Investing in medical displays is a significant commitment. When a screen fails prematurely, it disrupts critical procedures and strains budgets. Understanding what makes a display last is key to protecting this investment and ensuring uninterrupted patient care, a challenge I’ve helped countless hospitals navigate.

A medical display’s longevity is determined by a combination of critical factors. The most pivotal include:

- Operating Temperature and Thermal Management

- Backlight Technology and Longevity

- Power Supply Stability and Protection

- Usage Patterns and Operational Hours

- Environmental Humidity and Moisture Risks

- Chemical Resistance to Cleaning Agents

- Prevention of Image Retention and Burn-In

- The Manufacturer’s Core Engineering Philosophy

Let’s explore these eight factors to help you make more informed decisions and maximize the life of your equipment.

1. Operating Temperature and Thermal Management?

Intense heat in an operating room can compromise display performance. This can lead to screen flickering or outright failure mid-procedure. Effective, reliable cooling is therefore absolutely essential for operational safety.

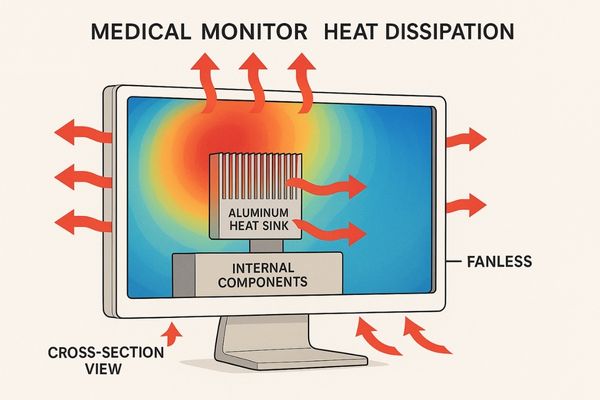

Surgical monitors must dissipate heat effectively to prevent component degradation and maintain image stability. An advanced thermal management system, including passive cooling and fanless designs, is crucial for extending lifespan and ensuring consistent performance in demanding environments.

From my experience, thermal management1 is one of the most overlooked yet critical aspects of display longevity. Every electronic component, from the processor to the LCD panel itself, generates heat. In a sealed, sterile environment like an operating room, this heat has nowhere to go without a purpose-built dissipation system. Sustained high temperatures can accelerate the aging of internal components, leading to color shifts, decreased brightness, and eventually, total failure. At Reshin, we prioritize fanless designs that use conductive cooling2. The aluminum alloy chassis of our monitors, such as the large-format MS550P 4K Surgical Monitor, acts as a giant heat sink, passively drawing warmth away from sensitive electronics without the need for failure-prone fans that can circulate contaminants. This silent, reliable cooling ensures stable performance during long procedures and significantly extends the monitor’s service life.

| Cooling Method | Pros | Cons | Ideal Application |

|---|---|---|---|

| Passive (Heat Sink) | Silent, reliable, no moving parts | Less effective for extreme heat loads | Medical OR, Cleanrooms |

| Active (Fan-based) | High cooling capacity | Noise, potential point of failure, circulates dust | Consumer electronics, Data centers |

| Liquid Cooling | Superior heat dissipation | Complex, expensive, risk of leaks | High-performance computing |

2. Backlight Technology and Longevity?

An aging backlight means a dim, inaccurate display. This compromises diagnostic confidence and surgical precision. Modern LED technology provides a clear, long-lasting solution that I always recommend.

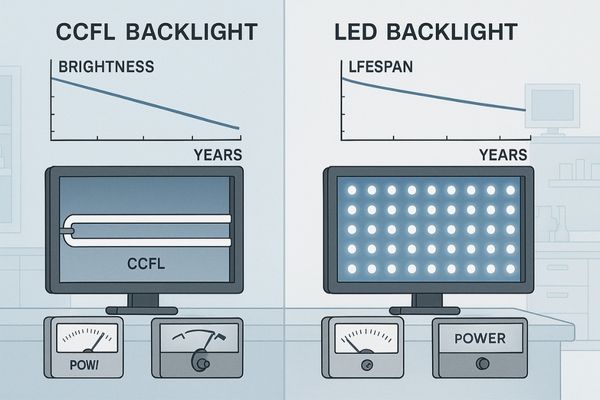

LED backlights offer a lifespan of 50,000 to 100,000 hours, far surpassing older CCFL technology. This ensures consistent brightness and color accuracy over many years, which is critical for medical imaging where visual fidelity is paramount.

The backlight is the heart of a display’s brightness and color reproduction. For years, Cold Cathode Fluorescent Lamps (CCFLs) were the standard, but their lifespan was limited, and their performance degraded unpredictably. I recall facilities struggling with monitors whose brightness would decline by 50% in just a few years. The shift to Light Emitting Diode (LED) backlights3 has been a game-changer. LEDs not only last three to five times longer but also maintain their brightness and color temperature with far greater stability. This consistency is vital for diagnostic displays that must adhere to the DICOM standard for grayscale imaging4. For a high-precision display like our MD120C 12MP monitor, a stable LED backlight with an integrated sensor ensures that the screen remains calibrated for accurate diagnosis throughout its entire lifespan, providing a reliable return on investment.

| Feature | LED Backlight | CCFL Backlight |

|---|---|---|

| Average Lifespan | 50,000 – 100,000 hours | 15,000 – 25,000 hours |

| Power Consumption | Low | High |

| Brightness Stability | High, consistent over time | Declines significantly with use |

| Environmental Impact | Mercury-free | Contains mercury |

3. Power Supply Stability and Protection?

Unstable power grids can silently kill expensive medical displays. A single surge can cause irreversible damage, leading to unexpected downtime and the high cost of replacement.

A stable, medical-grade power supply with built-in surge protection is essential. It shields sensitive internal components from electrical fluctuations, preventing catastrophic failures and ensuring the display operates reliably in critical hospital environments where power quality can vary.

Hospitals are complex electrical environments. With countless high-draw devices running simultaneously, power fluctuations like surges, sags, and electrical noise are common. A standard consumer-grade power supply is simply not built to withstand this. I’ve seen entire fleets of monitors fail prematurely due to inadequate power protection5. Medical-grade power supplies6, like those we integrate into our displays, are different. They provide superior filtering to clean up electrical noise and offer robust protection against voltage spikes. This ensures a clean, stable current reaches the delicate internal circuitry. For a large, central display in an integrated OR, such as the MS430PC 4K Surgical Monitor, this protection is non-negotiable. It’s the invisible shield that guarantees the monitor remains operational during the most critical moments.

4. Usage Patterns and Operational Hours?

Running monitors 24/7 seems necessary but drastically shortens their life. This constant use accelerates wear on every component, leading to premature aging and expensive replacement cycles.

Continuous operation accelerates wear on the backlight and electronic components. Features like automatic standby, presence sensors, and scheduled power-off modes can significantly mitigate this degradation, extending the monitor’s useful life without compromising its availability when needed.

A monitor’s lifespan is often measured in Mean Time Between Failures (MTBF)7, a metric directly influenced by operational hours. A display left on 24/7 will exhaust its backlight and stress its capacitors much faster than one used for 8-10 hours a day. In busy radiology reading rooms, for instance, displays are often left on overnight. To counter this, we build intelligent power management features8 into our products. Our diagnostic displays, including the MD52G 5MP Grayscale Mammography Monitor, can be configured with presence sensors that automatically dim the screen when the user steps away, and wake it instantly upon their return. This simple feature can add thousands of hours to a monitor’s operational life, reducing energy consumption and delaying capital expenditure without impacting clinical workflow.

5. Environmental Humidity and Moisture Risks?

Humidity and fluids are constants in clinical settings. Unprotected displays risk internal corrosion and short circuits, a silent threat that can cause sudden, catastrophic equipment failure.

Medical displays must have robust sealing, often meeting IPX ratings, to prevent moisture ingress from cleaning or spills. This protection is vital for preventing corrosion of internal circuits and ensuring safe, long-term operation in sterile environments.

The operating room is a challenging environment where accidental splashes and rigorous cleaning protocols are daily realities. Moisture is the enemy of electronics. If it seeps inside a monitor’s housing, it can corrode circuit boards and connectors, leading to intermittent failures or a complete short circuit. For this reason, we design our surgical monitors9 with protective sealing. The front panels of models like the MS275P 27" 4K Surgical Monitor are often rated to IP6510, meaning they are fully protected against dust ingress and low-pressure water jets. This robust construction ensures that routine cleaning and sterilization procedures won’t compromise the monitor’s internal components, guaranteeing both safety and a long, reliable service life in the most demanding settings.

6. Chemical Resistance to Cleaning Agents?

Harsh disinfectants are essential for infection control but can destroy monitor screens. This damage can compromise image quality and even void warranties, creating unexpected expenses and compliance issues.

Displays used in medical settings must feature chemically resistant materials and coatings. The housing and front screen need to withstand common hospital-grade cleaning agents without yellowing, cracking, or degrading, ensuring both safety and long-term durability.

Infection control is paramount, but the chemical agents used to achieve it can be incredibly destructive to plastics and screen coatings. I’ve seen monitor housings become brittle and screens develop a permanent haze from repeated exposure to the wrong type of cleaner. A truly medical-grade display must be built from materials selected for their chemical resilience11. We use specialized polymers for our housings and apply a protective, anti-glare tempered glass12 or PMMA layer on the front of our displays. This allows monitors like our portable MS192SA HD Endoscopic Monitor, which is frequently handled and cleaned between procedures, to withstand common disinfectants like isopropyl alcohol and quaternary ammonium compounds without damage, maintaining both optical clarity and structural integrity.

7. Prevention of Image Retention and Burn-In?

Static images on a screen can leave a permanent "ghost" behind. This burn-in degrades image quality, making accurate diagnosis impossible and rendering an expensive monitor useless.

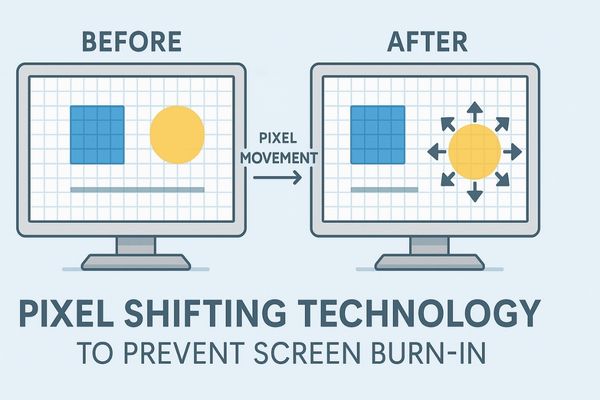

Image retention, or burn-in, occurs when static pixels are overused. Modern displays use technologies like pixel shifting, screen savers, and auto-dimming to mitigate this. These features are crucial for preserving image integrity, especially in applications with static user interfaces.

Image burn-in13 is a serious concern, particularly in diagnostic environments where parts of the screen may display a static software interface for hours on end. This can cause pixels to age unevenly, leaving a faint but permanent afterimage that interferes with the clinical image. To prevent this, we incorporate several protective measures. Pixel shifting14, for example, subtly moves the entire image by a few pixels periodically, ensuring that no single pixel is constantly illuminated. We also include a range of programmable screen savers and power-saving modes. On a workstation using our MD46C Dual-screen Diagnostic Monitor, these features work in the background to protect the panel during periods of inactivity, ensuring that the screen remains uniform and artifact-free for years of reliable use.

8. Reshin’s Engineering for Extended Lifespan?

Choosing a monitor based on specs alone is a gamble. Without a holistic focus on long-term reliability, you risk premature failure and performance issues despite impressive features on paper.

At Reshin, we design for longevity. By integrating industrial-grade components, long-life LED backlights, and advanced thermal management, our monitors are built to endure the rigors of continuous clinical use, ensuring a superior return on investment.

%[Blueprint of a Reshin medical display showing internal components](https://reshinmonitors.com/wp-content/uploads/2025/07/blueprint-Reshin-medical-display-internal-components-durable-design.jpg ‘Reshin\’s Engineering for Durability’)

Our entire design philosophy is built around durability. We know that a medical display is not a disposable commodity; it’s a critical asset. That’s why we don’t just assemble parts—we engineer a complete system. This approach is exemplified in models like the MS321PC 4K Surgical Monitor15. It combines a fanless cooling chassis, a 100,000-hour rated LED backlight, a medical-grade power supply16, and chemically-resistant housing into one cohesive unit. We source industrial-grade components with high MTBF ratings and subject our designs to rigorous testing that simulates years of hospital use. This is the same proven reliability that has made us a trusted OEM/ODM partner for global brands like Philips and Fujifilm, who rely on our engineering to prevent issues like image lag and color inconsistency in their own systems.

Conclusion

A monitor’s lifespan depends on a blend of technology, usage, and robust engineering. Choosing a display built for durability ensures long-term performance and value for any medical institution. For medical displays engineered for lasting reliability, contact Reshin at martin@reshinmonitors.com.

-

Understanding thermal management is crucial for ensuring the longevity and reliability of electronic devices, especially in sensitive environments. ↩

-

Exploring conductive cooling can reveal innovative solutions for efficient heat dissipation, enhancing device performance and lifespan. ↩

-

Explore this link to understand how LED backlights enhance display quality and longevity, crucial for professional use. ↩

-

Learn about the DICOM standard to appreciate its role in medical imaging and ensure compliance in diagnostic displays. ↩

-

Discover why power protection is essential for hospital equipment to prevent failures and ensure patient safety. ↩

-

Explore this link to understand how Medical-grade power supplies enhance safety and reliability in critical medical environments. ↩

-

Understanding MTBF helps in evaluating monitor reliability and lifespan, crucial for informed purchasing decisions. ↩

-

Exploring these features reveals how they enhance efficiency and longevity, making them essential for modern display technology. ↩

-

Explore this link to discover top-rated surgical monitors that ensure safety and reliability in demanding environments. ↩

-

Understanding the IP65 rating can help you choose electronics that withstand moisture and dust, crucial for operating room equipment. ↩

-

Explore this link to understand how chemical resilience is crucial for maintaining the integrity of medical displays. ↩

-

Discover the benefits of anti-glare tempered glass in medical settings and how it enhances display usability. ↩

-

Understanding image burn-in is crucial for maintaining monitor quality in clinical settings. ↩

-

Learn how pixel shifting technology can extend the life of your display and enhance image quality. ↩

-

Explore this link to understand how 4K Surgical Monitors enhance precision and clarity in medical procedures. ↩

-

Learn why a medical-grade power supply is crucial for safety and reliability in healthcare technology. ↩