Surgical displays are often heavy and difficult to maneuver on equipment booms. This makes positioning them during a procedure cumbersome, adding unnecessary strain and complexity to the operating room workflow.

Yes, carbon fiber can be used to create ultra-light surgical displays. Its exceptional strength-to-weight ratio allows for the design of durable, rigid, and significantly lighter monitor housings compared to traditional materials like aluminum or plastic.

In the modern operating room, every piece of equipment must be optimized for performance, usability, and safety. The weight and bulk of a surgical monitor directly impact how easily it can be positioned and handled. While traditional materials like aluminum and medical-grade plastics have served well, they have limitations. The pursuit of even lighter and more durable equipment has led many industries to adopt advanced composite materials. Carbon fiber is at the forefront of this movement. Its unique properties present an exciting opportunity to revolutionize surgical display design1. This article explores the potential of using carbon fiber2, examining its advantages, challenges, and practical applications in the medical field.

What Are the Mechanical Advantages of Carbon Fiber in Medical Equipment?

You need a display that is both lightweight and extremely sturdy. Standard materials force a trade-off; lighter plastics can feel flimsy, while strong metals add significant weight, straining mounting systems.

Carbon fiber’s main advantage is its remarkable strength-to-weight ratio. It is significantly lighter than aluminum yet can be engineered to be much stronger and more rigid, preventing flex and vibration.

The mechanical properties of carbon fiber composite3 make it an exceptional material for high-performance applications. It is created by embedding carbon fibers in a polymer resin, resulting in a material that is both incredibly strong and surprisingly light. For medical equipment, this means we can design a monitor housing that is far less bulky without sacrificing durability. This is especially important for displays mounted on surgical booms or mobile carts. A lighter display reduces the load on articulated arms, allowing for smoother, more precise positioning with less effort. It also reduces the risk of mechanical sag over time, ensuring the display stays exactly where the surgeon needs it. The material’s inherent stiffness also helps to dampen vibrations, which can be critical for maintaining a stable, clear image during a procedure. Our current models, like the MS275P 27" 4K Surgical Monitor, already use lightweight materials4, but exploring carbon fiber could push these weight savings even further.

Is Carbon Fiber Suitable for Sterilization and Cleaning Protocols?

You worry that a new, advanced material might not hold up to harsh hospital disinfectants. If a material degrades or cannot be properly cleaned, it is unusable in a sterile environment.

Yes, carbon fiber can be made suitable for sterilization. While raw carbon fiber composite can be porous, it is sealed with a medical-grade resin or coating that makes it non-porous and resistant to chemical disinfectants.

The ability to withstand rigorous cleaning protocols is non-negotiable for any equipment used in the operating room. Raw, unfinished carbon fiber composite5 is not suitable for this environment because its microscopic surface texture could harbor contaminants. Therefore, any carbon fiber component for medical use must be completely sealed. This is typically achieved with a durable, non-porous topcoat. The specific resin or coating used is critical. It must create an impenetrable barrier that is chemically resistant to a wide range of common hospital-grade sterilizing agents6, such as hydrogen peroxide, bleach, and quaternary ammonium compounds. The surface must also be perfectly smooth, without any cracks or crevices where bacteria could accumulate. This finishing process is a key part of the manufacturing design, ensuring the final product is not only lightweight and strong but also safe and hygienic for clinical use. We apply similar principles of sealed design in our MS321PC 32" 4K Surgical Monitor to ensure its enclosure can be easily and effectively cleaned.

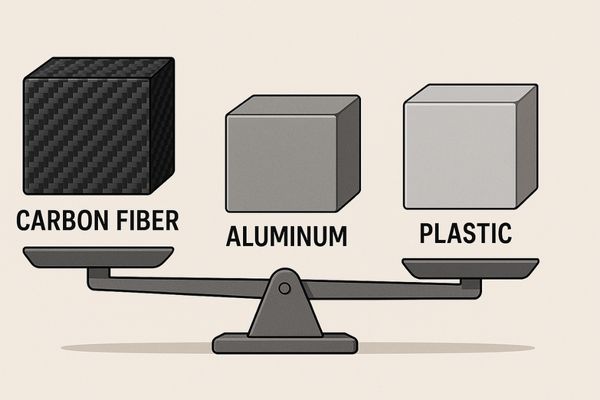

How Does Carbon Fiber Compare to Aluminum and Plastics in Weight Reduction?

You want the lightest possible display, but you are unsure which material truly delivers the best results. It is difficult to know if the benefits of an advanced material justify its adoption.

Carbon fiber offers the most significant weight reduction. For the same level of strength and rigidity, a carbon fiber housing can be up to 50% lighter than aluminum and 20-30% lighter than standard plastics.

When it comes to pure weight savings without compromising structural integrity, carbon fiber stands in a class of its own. While lightweight metals like aluminum are a significant improvement over steel, carbon fiber takes it a step further. Its low density combined with its high tensile strength allows engineers to design parts that use far less material to achieve the same or even greater stiffness than a metal equivalent. Plastics like ABS are very light, but they cannot match the rigidity of carbon fiber7, meaning a plastic housing might require thicker walls or internal ribbing to prevent flexing, which adds back weight. This makes carbon fiber particularly compelling for large-format displays, where the overall weight of the housing is a major factor. A lighter 55-inch display, for example, is far easier to install and safer to mount. The benefits of this weight reduction8 are already a focus in our large displays, such as the MS550P 55" 4K Surgical Monitor, and carbon fiber could enhance this advantage even more.

Material Property Comparison

| Property | Carbon Fiber Composite | Aluminum (6061) | ABS Plastic |

|---|---|---|---|

| Density (g/cm³) | ~1.6 | ~2.7 | ~1.04 |

| Tensile Strength (MPa) | High (600 – 1500+) | Medium (~310) | Low (~40) |

| Stiffness (GPa) | Very High (70 – 200+) | High (~69) | Low (~2.3) |

| Relative Weight | Lightest | Medium | Light |

Are There Cost Considerations When Using Carbon Fiber for Display Housings?

You are intrigued by the benefits of carbon fiber, but you suspect it comes at a high price. The cost of new technology is often a major barrier to its adoption in practice.

Yes, cost is the primary challenge. The raw materials are expensive, and the manufacturing process is labor-intensive and complex, making carbon fiber monitor housings significantly more costly to produce than those made from plastic or aluminum.

While the performance benefits of carbon fiber are clear, its cost remains a significant hurdle. The process of creating a carbon fiber9 part is far more complex than injection molding plastic or machining aluminum. It involves manually laying sheets of carbon fiber fabric into a mold, infusing them with resin, and then curing them under heat and pressure for several hours. This is a slow, labor-intensive process that requires skilled technicians and expensive tooling. The raw materials themselves are also much more expensive than aluminum billets or plastic pellets. This combination of high material cost and complex manufacturing means that a carbon fiber housing for a surgical display could be several times more expensive to produce than a conventional one. This cost must be weighed against the performance benefits, making it a solution best suited for premium, specialized applications where minimal weight is the absolute top priority. This cost-benefit analysis10 is something we always consider when developing products like our MS247SA 24" FHD Endoscopic Monitor.

Cost Breakdown for Housing Production

| Cost Factor | Injection-Molded Plastic | Machined Aluminum | Carbon Fiber Composite |

|---|---|---|---|

| Raw Material Cost | Low | Medium | Very High |

| Tooling/Mold Cost | High | Medium | High |

| Labor & Cycle Time | Very Low | Medium | Very High |

| Overall Unit Cost | Low | Medium | High |

How Is Reshin Exploring Advanced Materials Like Carbon Fiber in Surgical Display Design?

You want a partner who is always looking ahead. You need to know that your supplier is investing in future technologies that will improve the tools you use every day.

We are actively researching and prototyping with advanced composites, including carbon fiber. Our goal is to develop the next generation of ultra-light surgical monitors that are easier to mount and maneuver without sacrificing the durability and image quality our customers expect.

Innovation is at the core of our mission. We are constantly exploring new materials and manufacturing techniques to enhance the performance and usability of our products. Our research and development team is currently investigating the feasibility of incorporating carbon fiber and other lightweight composites11 into future surgical display designs. This process involves more than just swapping one material for another. We are building prototypes to analyze the real-world benefits in weight reduction, rigidity, and handling. At the same time, we are conducting a thorough analysis of the manufacturing challenges and cost implications. Our aim is to find the right balance—where the tangible benefits for the surgeon justify the investment in advanced technology. This forward-looking research ensures that we can continue to offer best-in-class solutions, from our current reliable models like the MS430PC 43" 4K Surgical Monitor to the next wave of innovation in medical imaging.

Conclusion

Carbon fiber offers tremendous potential for creating lighter, stronger surgical displays. While high costs present a challenge, ongoing research is paving the way for its future use in specialized medical equipment. To stay informed about innovative materials in medical displays, contact Reshin at martin@reshinmonitors.com.

-

Learn about the latest innovations in surgical display design and how they improve usability and efficiency in operating rooms. ↩

-

Discover how carbon fiber can enhance surgical equipment performance and safety, making it a game-changer in the medical field. ↩

-

Discover how carbon fiber composite enhances medical equipment performance and durability, making it a game-changer in healthcare. ↩

-

Learn how lightweight materials revolutionize surgical monitor design, enhancing mobility and precision in medical settings. ↩

-

Explore this link to understand how carbon fiber composites enhance medical equipment durability and safety. ↩

-

Learn about hospital-grade sterilizing agents to ensure effective cleaning and safety in healthcare environments. ↩

-

Explore the benefits of carbon fiber in engineering to understand its superior strength-to-weight ratio and applications. ↩

-

Learn how weight reduction can enhance installation safety and efficiency for large-format displays. ↩

-

Exploring this resource will provide insights into the benefits and challenges of using carbon fiber, essential for informed decision-making. ↩

-

This link will guide you through the process of performing a cost-benefit analysis, crucial for evaluating material choices in production. ↩

-

Discover the impact of lightweight composites on surgical displays, focusing on performance and usability enhancements. ↩