A splash of saline solution hits your monitor during a procedure, causing flickering and eventual failure. This equipment damage not only disrupts the surgery but requires costly replacement and creates infection control concerns.

For surgical monitors, IPX4 is typically enough while IPX1 is insufficient. IPX1 only protects against vertically dripping water, offering minimal protection in medical settings. IPX4 resists splashes from all directions, making it suitable for operating rooms where liquids frequently spray during procedures and cleaning.

When selecting monitors for surgical environments, waterproofing1 is not merely a convenience feature—it’s a critical safety and longevity consideration. Medical devices in operating rooms are routinely exposed to bodily fluids, irrigation solutions, and aggressive disinfectants. A monitor that fails due to liquid ingress doesn’t just represent a financial loss; it can disrupt critical procedures and compromise patient care. The distinction between IPX1 and IPX4 ratings2 might seem subtle on paper, but in practice, it represents a significant difference in protection capability. Understanding these ratings and matching them to your specific needs can prevent costly equipment failures and ensure your displays remain functional through years of clinical use. This article explores the real-world implications of these waterproof standards and helps you determine the appropriate level of protection for your facility’s needs.

What do IPX1 and IPX4 waterproof ratings specifically mean?

You see "IPX4" on a product specification but wonder if the less expensive "IPX1" option would suffice. The technical descriptions sound vague, making it difficult to translate these ratings into practical protection levels.

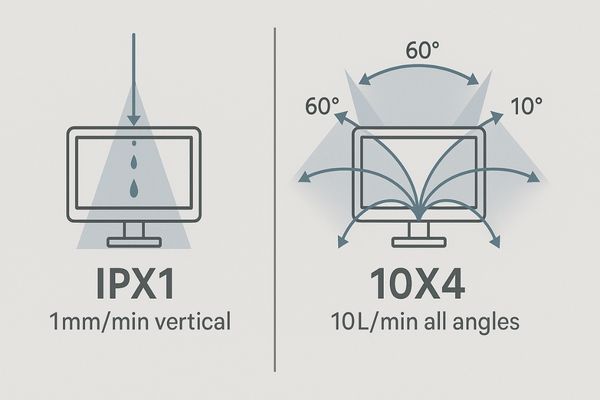

IPX1 means the device is protected against vertically falling water drops, simulating light condensation or minimal dripping. IPX4 provides significantly more protection, resisting water splashed from any angle up to 60 degrees from vertical. This represents protection against real-world sprays and splashes from multiple directions.

The IP (Ingress Protection3) rating system was developed by the International Electrotechnical Commission (IEC) to provide a standardized method for evaluating the protection level of electrical equipment against solid particles and liquids. The "X" in IPX1 and IPX4 indicates that the solid particle protection level (normally the first digit) is unspecified, while the second digit specifically addresses liquid ingress protection. For IPX14, the testing procedure involves dripping water equivalent to 1mm of rainfall per minute for 10 minutes from directly overhead. This simulates minimal exposure—essentially light dripping or condensation. In contrast, IPX45 testing is much more rigorous. The equipment is sprayed with water from a nozzle or oscillating tube from all directions for at least 10 minutes, with a flow rate equivalent to 10 liters per minute. The water pressure is set at 80-100 kPa and sprayed from a distance of 300-500mm. This simulates real splashing scenarios that might occur in clinical environments. The MS321PC monitor undergoes this exact testing to ensure its water resistance meets operating room requirements, providing a reliable defense against the unpredictable nature of liquid exposure during procedures.

IP Rating System Explained

| IP Code Component | Meaning | Example |

|---|---|---|

| First Digit (0-6) | Protection against solid objects/particles | 5 = Dust protected, 6 = Dust tight |

| Second Digit (0-9) | Protection against liquids | 1 = Dripping water, 4 = Water splashes |

| IPX1 Test | Device rotated at 1 RPM while water drips from above at 1mm/min for 10 minutes | Similar to light rain directly overhead |

| IPX4 Test | Water splashed from all directions at 10L/min with pressure of 80-100 kPa for 10 minutes | Similar to splashing from any angle |

| Common Applications | IPX1: Indoor electronics with minimal liquid exposure IPX4: Bathroom electronics, outdoor equipment, medical devices |

IPX1: Standard monitors IPX4: Surgical displays, patient monitors |

How much water exposure occurs in a typical operating room environment?

You might think that operating rooms are primarily dry environments. But you’re uncertain about how much liquid exposure your equipment truly faces during regular use and cleaning procedures.

Typical operating rooms expose equipment to significant liquid contact. During procedures, monitors may encounter splashes from irrigation fluids (1-3L per case), bodily fluids, and saline sprays. Cleaning protocols involve multiple daily disinfectant sprays from various angles, often with alcohol-based solutions that can penetrate casings more easily than water.

The operating room6 is an inherently wet environment, with liquids used throughout surgical procedures. In orthopedic surgeries, irrigation fluids are frequently used to clean tissue sites, creating splashes that can travel several feet. In laparoscopic procedures, condensation from the patient’s internal cavity can spray when instruments are exchanged. Even in seemingly "dry" procedures, unexpected bleeding or fluid release can occur. Beyond the procedure itself, operating room equipment is subjected to stringent cleaning protocols. Between cases, rapid turnover cleaning often involves liberal application of disinfectants sprayed directly onto surfaces. At the end of the day, terminal cleaning is even more thorough, with disinfectants7 applied from multiple angles to ensure complete coverage. These disinfectants often contain alcohols or quaternary ammonium compounds that can penetrate small openings more effectively than water alone. The MS270P monitor is designed with these realities in mind, featuring sealed edges and protected ventilation openings that prevent liquid ingress during normal OR operations while still allowing for proper thermal management.

Is IPX1 sufficient for surgical monitors that undergo frequent cleaning?

Your budget constraints make the less expensive IPX1 monitors tempting. However, you’re concerned about whether they’ll withstand your facility’s rigorous cleaning protocols over time.

No, IPX1 is insufficient for surgical monitors that undergo frequent cleaning. IPX1 only protects against vertically dripping water, while cleaning involves sprays from multiple angles. Disinfectants are often more penetrating than water and applied under pressure. IPX1 monitors typically fail prematurely in healthcare settings due to liquid damage during routine disinfection.

The limitations of IPX1 protection8 become immediately apparent when considering modern infection control protocols. In today’s healthcare facilities, especially post-pandemic, cleaning has intensified significantly. Surface disinfection is no longer a simple matter of light wiping—it now involves thorough spraying of disinfectants to ensure coverage of all surfaces, including sides and backs of equipment. An IPX1 rating assumes water ingress will only come from above, in a controlled dripping fashion. This fails to account for the reality of disinfection procedures, where liquids are applied from multiple angles, often with some pressure to ensure proper coverage. Moreover, many disinfectants have different viscosity and surface tension properties than pure water, allowing them to penetrate smaller openings in device casings. This creates a significant risk for electronic components inside the monitor. The MS430PC monitor addresses these challenges with comprehensive sealing around all potential ingress points—including button interfaces, ventilation openings, and cable connections—ensuring that it can withstand years of aggressive cleaning without internal damage.

When should medical facilities consider choosing IPX4-rated equipment?

You recognize the extra cost of IPX4-rated monitors, and wonder whether this higher standard is truly necessary for your specific department or if it’s an unnecessary expense.

Medical facilities should choose IPX4-rated equipment in any environment where fluid splashes are possible or where thorough disinfection is required. This includes all operating rooms, interventional suites, emergency departments, and intensive care units. The minimal cost difference is justified by significantly longer equipment lifespan and reduced failure rates.

The decision to invest in IPX4-rated equipment9 should be based on a realistic assessment of the environment and the total cost of ownership10, not just initial purchase price. Beyond the obvious high-fluid environments like operating rooms, many medical settings present hidden risks to electronic equipment. In emergency departments, the unpredictable nature of cases means equipment may be exposed to bodily fluids without warning. In intensive care units, bedside procedures and frequent cleaning create regular exposure to liquids. Even in seemingly controlled environments like catheterization labs or ultrasound rooms, the combination of gel products and disinfection protocols creates significant fluid exposure over time. When calculating the true cost difference between IPX1 and IPX4 equipment, facilities must consider not just the purchase price, but also: replacement costs for prematurely failed equipment11, downtime and procedural delays when equipment fails, infection control risks if equipment cannot be properly cleaned, and maintenance costs associated with liquid damage. The MS247SA monitor, with its IPX4 rating, may represent a slightly higher initial investment, but this is quickly offset by its significantly longer functional lifespan in clinical environments.

Cost Analysis: IPX1 vs. IPX4 Monitors Over 5 Years

| Cost Factor | IPX1 Monitor | IPX4 Monitor |

|---|---|---|

| Initial Purchase | $4,500 | $5,200 |

| Average Lifespan | 2-3 years in medical settings | 5+ years in medical settings |

| Replacement Frequency | 1-2 times in 5 years | Typically 0 in 5 years |

| Downtime Costs | $2,000-4,000 (1-2 incidents) | Minimal |

| Maintenance Visits | 3-5 service calls | 0-1 service calls |

| Total 5-Year Cost | $10,500-13,000 | $5,200-6,000 |

How does Reshin address waterproofing in its surgical monitor designs?

You’ve experienced previous monitors that claimed water resistance but still failed after cleaning. You’re skeptical about manufacturer claims and want to understand the actual design elements that contribute to genuine waterproofing.

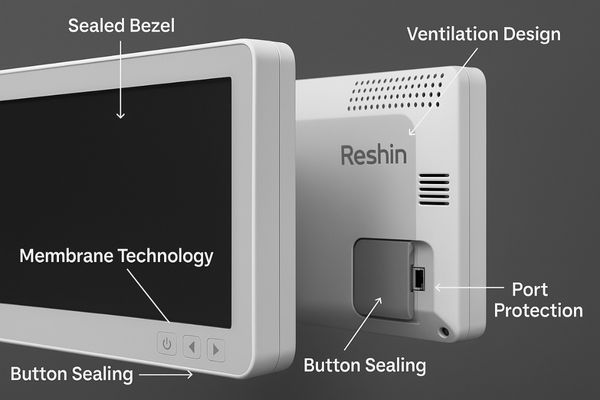

Reshin addresses waterproofing through comprehensive design rather than surface treatments. Our monitors feature fully sealed bezels with specialized gaskets, protected rear ventilation systems that prevent vertical water entry, hermetically sealed button interfaces, and reinforced I/O panels with water-resistant port designs—all validated through rigorous testing beyond standard IPX4 requirements.

Waterproofing is not an afterthought in our design process but a foundational consideration from the earliest stages of product development. Unlike manufacturers who simply add water-resistant coatings12 to standard commercial designs, we engineer our monitors from the ground up for medical environments. This begins with a specialized front bezel design that incorporates medical-grade silicone gaskets13 between the screen and frame, creating a complete seal against liquid ingress. The monitor housing uses a unibody design whenever possible to minimize seams where liquids could penetrate. For necessary openings like ventilation, we implement a labyrinth design—a series of baffles that allow air to flow while preventing direct water pathways to internal components. All control interfaces, whether touch buttons or physical controls, use sealed membrane technology rated independently for water resistance. Even the mounting systems are designed with water drainage channels to prevent pooling around potential entry points. The MS275P exemplifies this approach with its streamlined design that eliminates unnecessary seams while maintaining a slim profile. This comprehensive approach ensures that the IPX4 rating14 is not just met but exceeded, providing reliable protection throughout years of clinical use.

Conclusion

For surgical environments, IPX1 is insufficient while IPX4 provides the necessary protection against splashes from all directions. This higher standard ensures monitors can withstand both procedural fluids and thorough disinfection, justifying the modest price difference through significantly longer equipment life. To upgrade to surgical displays with robust IPX4 protection, contact Reshin at martin@reshinmonitors.com.

-

Exploring waterproofing benefits can enhance your understanding of its critical role in surgical settings, ensuring safety and longevity. ↩

-

Understanding the differences between these ratings is essential for selecting the right equipment to protect patient care and prevent failures. ↩

-

Understanding Ingress Protection ratings is crucial for selecting the right equipment for safety and reliability in various environments. ↩

-

Exploring the specifics of the IPX1 rating helps in assessing the suitability of equipment for environments with minimal water exposure. ↩

-

Learning about the differences between IPX1 and IPX4 ratings can guide you in choosing equipment that can withstand more rigorous water exposure. ↩

-

Explore this link to understand essential practices that ensure a safe and sterile operating room, crucial for successful surgeries. ↩

-

Learn about the most effective disinfectants used in surgical settings to enhance safety and prevent infections during procedures. ↩

-

Understanding the limitations of IPX1 protection is crucial for ensuring the safety and longevity of medical equipment in modern healthcare environments. ↩

-

Explore the advantages of IPX4-rated equipment to understand its importance in protecting electronic devices in medical environments. ↩

-

Understanding total cost of ownership helps in making informed decisions about medical equipment investments, ensuring long-term savings. ↩

-

Learn about the financial impact of equipment failure and how it affects healthcare facilities’ budgets and operations. ↩

-

Explore how water-resistant coatings enhance the durability and reliability of medical devices, ensuring safety in clinical environments. ↩

-

Learn about the importance of medical-grade silicone gaskets in creating effective seals for medical monitors, enhancing their performance. ↩

-

Understand the significance of the IPX4 rating in ensuring water resistance for medical equipment, crucial for clinical safety. ↩