A standard office monitor can fail to show critical medical details. This failure can lead to diagnostic errors and patient harm. Medical displays built to strict standards ensure accuracy and safety.

Medical displays must adhere to rigorous development standards because clinical imaging demands higher precision than consumer-grade monitors. These standards ensure the accuracy, consistency, and safety necessary for reliable diagnosis.

These strict standards are not arbitrary rules. They are the foundation of diagnostic confidence1. For anyone involved in procuring or using medical equipment2, understanding these requirements is essential. Let’s explore why these standards are so critical for modern healthcare.

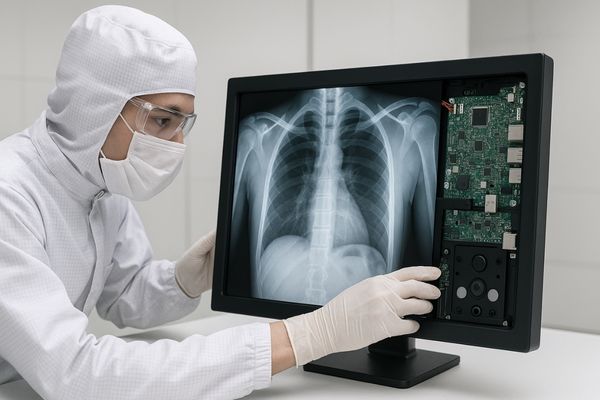

Medical Imaging Demands High Precision in Displays

Subtle grayscale variations can signal a serious condition. A consumer display might miss these nuances entirely. Medical displays are engineered to render every minute detail with absolute clarity.

In medical imaging, the smallest visual detail can be diagnostically significant. Therefore, medical displays require exceptionally high precision in brightness, contrast, and color fidelity to ensure accurate clinical interpretation.

The difference between a consumer monitor and a medical display comes down to precision. In radiology, a faint shadow on a lung X-ray or a subtle change in tissue density on a CT scan might be the only sign of an early-stage tumor. These details are represented by very small differences in grayscale values. A standard monitor lacks the luminance range and calibration to distinguish these subtle steps accurately, a concept known as Just-Noticeable Difference (JND)3. Medical displays are designed to meet specific JND standards, ensuring a perceptible difference for every grayscale value. Similarly, in color-dependent fields like pathology or endoscopy, accurate color reproduction4 is paramount. The exact shade of a stained tissue sample can differentiate between benign and malignant cells. Our MD120C – 12MP High-Precision Diagnostic Monitor with AI Calibration is designed for these scenarios. Its immense resolution and intelligent calibration systems ensure that every pixel and color value is rendered with the utmost fidelity, leaving no room for ambiguity.

Regulatory Bodies Define Strict Performance Criteria

Using an unregulated display for clinical work is a significant risk. It lacks the validated performance needed for patient care. Regulatory standards provide the necessary framework for quality and safety.

Global regulatory bodies, such as the FDA and CE, enforce stringent performance criteria for medical displays. These rules govern critical parameters to safeguard patient safety and ensure diagnostic reliability.

Medical displays are classified as medical devices for a reason. Their performance directly impacts patient outcomes. To manage this, regulatory bodies worldwide have established comprehensive standards. In the United States, the Food and Drug Administration (FDA) often requires 510(k) clearance5, demonstrating that a device is safe and effective. In Europe, the CE mark under the Medical Device Regulation (MDR) is mandatory. These certifications are not just paperwork. They require manufacturers to provide extensive evidence that their displays meet specific criteria for luminance, contrast, color accuracy, and image uniformity. They also mandate quality management systems for design and production. For example, the DICOM Part 14 standard6 is a global benchmark for grayscale calibration. Adhering to these regulations is a non-negotiable part of our development process. Our MD85CA – 8MP Multi-modality Diagnostic Monitor meets these international standards, making it a reliable choice for hospitals that need versatile and compliant imaging solutions.

| Standard/Regulation | Focus Area | Key Requirement |

|---|---|---|

| DICOM Part 14 | Grayscale Display | Adherence to the Grayscale Standard Display Function (GSDF) for perceptual linearity. |

| FDA 510(k) | Device Safety & Efficacy | Demonstration of substantial equivalence to a legally marketed device. |

| CE (MDR) | Health & Safety | Compliance with comprehensive safety and performance requirements for the EU market. |

| AAPM TG18 | Quality Control | Provides detailed test patterns and procedures for evaluating display performance. |

Consistency Across Devices Reduces Diagnostic Errors

An image viewed in radiology can look different in the operating room. This inconsistency creates a chain of uncertainty. Standardized displays ensure that every clinician sees the exact same image.

When image presentation varies between displays, the risk of misdiagnosis increases. Standardized displays provide visual consistency across a hospital, which is crucial for reliable consultations and accurate longitudinal studies.

In a hospital, a patient’s journey involves many specialists. A radiologist makes an initial reading, a surgeon reviews the scan for planning, and other physicians may consult on the case. If each specialist views the image on a monitor with different calibration, brightness, and contrast settings, they are not truly seeing the same information. A subtle finding visible on a high-contrast radiology monitor might be lost on a standard desktop screen. This is why consistency is a cornerstone of patient safety. By calibrating all displays to a common standard like DICOM7, we ensure that the image integrity is maintained everywhere. This is also vital for tracking a patient’s condition over time. Comparing a new scan to one taken six months ago is only meaningful if the displays render both images identically. Our MD45C – Dual-screen Diagnostic Monitor8 (Single Panel) addresses this challenge directly. By presenting two images on a single, seamless panel, it eliminates the slight variations that can exist even between two matched monitors, guaranteeing perfect consistency.

Testing Protocols Validate Display Quality and Safety

A new display may perform well initially. But will it remain accurate after years of constant use? Rigorous testing protocols are designed to validate long-term performance and safety.

Extensive testing protocols are essential to validate a medical display’s initial quality, long-term stability, and operational safety. This ensures the device performs reliably throughout its entire lifecycle in a clinical setting.

Manufacturing a medical display is more than just assembling components. It involves a deep commitment to quality validated through rigorous testing. These tests go far beyond a simple power-on check. We conduct performance testing9 using protocols like those from the American Association of Physicists in Medicine (AAPM TG18) to measure luminance, uniformity, and resolution. We also perform long-term stability tests, running displays for thousands of hours at high brightness to ensure they resist image retention and maintain color accuracy. Safety is another critical dimension. All our displays undergo stringent electrical safety tests10 to prevent any risk to patients or staff in the operating room. For surgical displays like our MS430PC – 43" 4K Surgical Monitor, we conduct additional tests for things like ingress protection, ensuring the housing is sealed against fluids. This multi-layered testing process guarantees that every monitor we ship is not only accurate but also durable and safe for clinical use.

Future Standards Will Integrate AI and Advanced Analytics

The volume and complexity of medical images are increasing rapidly. Manual review is becoming more challenging and time-consuming. Future standards will need to accommodate AI-driven tools to assist clinicians.

The next generation of medical display standards will likely incorporate protocols for AI and advanced analytics. This evolution is necessary to manage increasingly complex imaging data and support more sophisticated diagnostic workflows.

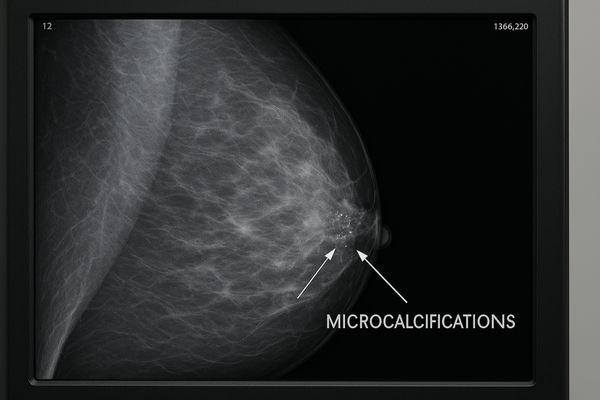

The role of the medical display is evolving from a passive viewing device to an active partner in the diagnostic process. As artificial intelligence becomes more integrated into healthcare, displays will need to do more than just show pictures. Future standards will have to address this shift. We can expect to see requirements for how displays handle AI-generated overlays11, such as those that automatically highlight suspicious nodules or measure anatomical structures. Standards will be needed to ensure these AI features are displayed accurately and do not obscure critical underlying information. Displays may also need to integrate with hospital analytics platforms to help prioritize worklists or flag cases that require urgent attention. This fusion of display technology and AI will help clinicians manage their workload and improve diagnostic efficiency12. High-precision displays like our MD52G – 5MP Grayscale Mammography Monitor provide the perfect canvas for these future tools, where the clarity of the underlying image is essential for the AI to function effectively.

Conclusion

Strict development standards are not a burden. They are the essential guarantee of quality, precision, and safety in medical displays. This commitment provides the foundation for diagnostic confidence and superior patient care. To learn more about Reshin’s commitment to high development standards in medical displays, contact us at martin@reshinmonitors.com.

-

Understanding diagnostic confidence is crucial for ensuring accurate medical assessments and improving patient outcomes. ↩

-

Exploring the standards for medical equipment can help ensure safety, efficacy, and compliance in healthcare settings. ↩

-

Understanding JND is crucial for appreciating how medical displays ensure precision in diagnostics. ↩

-

Explore the significance of color accuracy in distinguishing between benign and malignant cells in pathology. ↩

-

Understanding 510(k) clearance is crucial for manufacturers to ensure their devices meet safety and effectiveness standards. ↩

-

Exploring the DICOM Part 14 standard helps in grasping the importance of grayscale calibration in medical imaging. ↩

-

Understanding DICOM is crucial for ensuring image consistency in medical imaging, which directly impacts patient safety. ↩

-

Exploring the advantages of dual-screen monitors can enhance your understanding of their role in improving diagnostic accuracy and patient care. ↩

-

Understanding performance testing is crucial for ensuring the quality and reliability of medical displays, which directly impacts patient safety. ↩

-

Exploring the importance of electrical safety tests can provide insights into how they protect patients and staff in medical environments. ↩

-

Understanding AI-generated overlays is crucial for grasping how technology enhances diagnostic accuracy in healthcare. ↩

-

Exploring diagnostic efficiency can reveal how modern displays optimize clinical workflows and patient outcomes. ↩