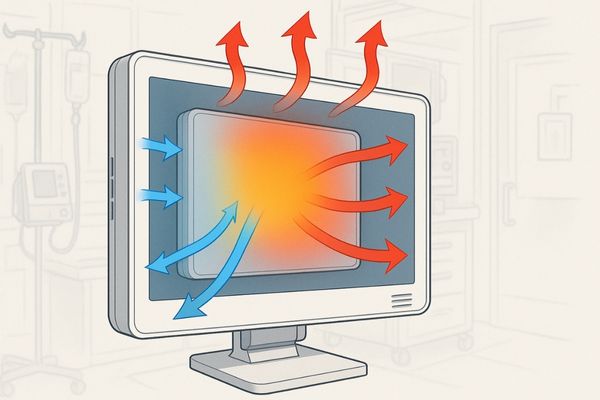

Medical displays often run for extended periods, and overheating can become a serious concern. This impacts performance and reliability when they are needed most. Understanding how to prevent this is key.

To avoid overheating in continuous-use displays, ensure they have efficient thermal management designs, such as adequate ventilation, heat sinks, and thermally conductive materials. Proper placement and ambient conditions also play a crucial role in maintaining optimal operating temperatures.

Displays used constantly in medical settings, from patient monitoring to surgical navigation, face the challenge of heat buildup. If not managed effectively, this can lead to a host of problems. We will explore why medical displays1 overheat, what design features help prevent it, compare cooling systems2, discuss the risks of prolonged overheating, and outline how we ensure thermal stability3 in our products

Why do medical displays overheat during continuous operation?

A display that suddenly becomes too hot to touch or shows image distortions can be alarming. This isn’t a random occurrence; specific components are responsible for this heat generation, especially under constant load.

Medical displays can overheat during continuous operation because key internal components like LCD drivers, power supply units, and backlight LED modules generate significant heat. Without effective heat dissipation mechanisms, this thermal energy accumulates.

Several internal components contribute to heat generation within a medical display, particularly when it operates for many hours without interruption. The Liquid Crystal Display (LCD) panel4 itself, or more specifically, the driver electronics that control the pixels, produce heat as they work. The backlight unit, which illuminates the screen, is another major heat source. Modern displays typically use Light Emitting Diodes (LEDs)5 for backlighting, and while LEDs are more efficient than older technologies like CCFLs, a large array of high-brightness LEDs still generates considerable thermal energy. Furthermore, the internal power supply unit6, which converts AC power from the wall outlet to the various DC voltages needed by the display’s circuitry, also produces heat as a byproduct of power conversion. During continuous operation, these components are constantly active, leading to a steady accumulation of heat. If this heat is not effectively removed from the system, the internal and surface temperatures of the display will rise, potentially leading to performance issues or component degradation.

What design features help prevent thermal buildup in displays?

A display that stays cool even after hours of use is often the result of careful engineering. Specific design choices can make a big difference in managing the heat generated internally.

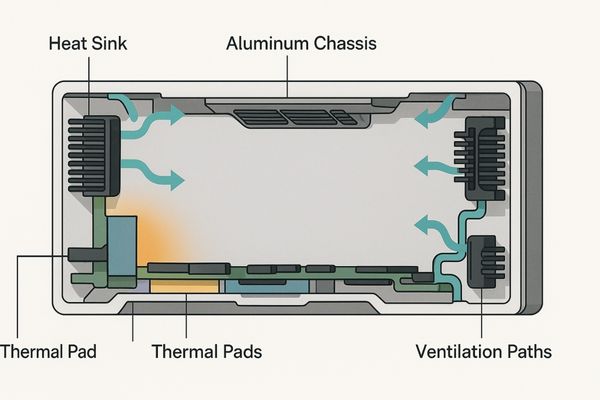

Design features that help prevent thermal buildup include ventilated chassis designs, the use of thermally conductive materials like aluminum for enclosures, and the strategic internal placement of heat sinks to draw heat away from critical components.

Effective thermal management7 in a display begins at the design stage. One common approach is to incorporate ventilation into the display’s enclosure. This can involve strategically placed vents or grilles that allow cooler ambient air to enter and warmer internal air to escape, facilitating natural convection. However, in medical environments, completely sealed units are often preferred for hygiene, so other methods become more critical. The choice of materials for the display’s housing plays a significant role. Metals like aluminum are excellent thermal conductors. Using an aluminum chassis8 or back panel allows heat generated by internal components to spread out over a larger surface area and dissipate more efficiently into the surrounding environment.

Internally, heat sinks9 are crucial. These are typically pieces of metal with a large surface area (often with fins) attached directly to heat-producing components like the main processor or power transistors. The heat sink absorbs thermal energy from the component and radiates it away, often into the path of any airflow or towards a conductive chassis. The layout of internal components is also considered to ensure that heat-generating parts are not clustered too closely together and have adequate pathways for heat to escape.

How do active vs. passive cooling systems compare?

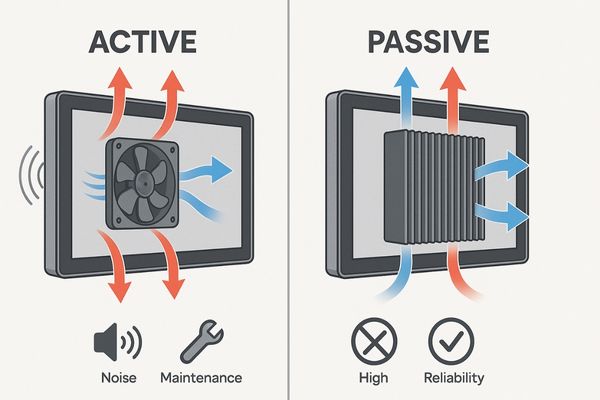

When it comes to removing heat, displays can use different strategies. Some use fans, while others rely on silent methods. Each approach has its own set of advantages and disadvantages for medical use.

Active cooling systems, like fans, offer rapid heat dissipation but can introduce noise and require maintenance. Passive cooling systems are quieter and more reliable, using heat sinks and convection, making them well-suited for many clinical environments.

Cooling systems in displays can be broadly categorized as active or passive. Each has distinct characteristics.

Active Cooling10

Active cooling systems involve components that consume energy to remove heat. The most common example is a fan, which forces air across hot components or out of the enclosure. Heat pipes are another active method, using a fluid phase-change cycle to transfer heat efficiently from a source to a dissipation area.

- Pros: Can remove large amounts of heat quickly, effective for high-power components.

- Cons: Fans generate noise, which can be distracting in quiet medical settings like reading rooms or bedside. They have moving parts that can fail and require maintenance (e.g., cleaning dust). Fans can also disrupt sterile airflow patterns in operating rooms.

Passive Cooling11

Passive cooling relies on natural processes like convection, conduction, and radiation to dissipate heat without powered components. This typically involves large heat sinks, thermally conductive chassis materials, and well-designed ventilation paths for natural airflow.

- Pros: Silent operation, no moving parts (higher reliability, no maintenance), does not disrupt airflow. Often results in sealed or semi-sealed designs which are easier to clean.

- Cons: May have a lower capacity for dissipating extremely high heat loads compared to aggressive active cooling. Performance can be more dependent on ambient temperature and orientation.

For many medical applications, especially those requiring low noise and high reliability, passive cooling systems are often preferred. The design must be carefully optimized to ensure sufficient heat dissipation12 without active components.

| Feature | Active Cooling (e.g., Fans) | Passive Cooling (e.g., Heat Sinks) |

|---|---|---|

| Noise Level | Can be noisy | Silent |

| Reliability | Moving parts can fail | Higher (no moving parts) |

| Maintenance | May require cleaning/replacement | Generally lower or none |

| Airflow Impact | Can disrupt local airflow | Minimal impact on ambient airflow |

| Heat Dissipation | High capacity, rapid | Moderate capacity, slower but steady |

| Suitability | High-power, less noise-sensitive | Noise-sensitive, high-reliability areas |

This table provides a clear comparison between active and passive cooling approaches.

What are the risks of prolonged overheating in medical monitors?

If a display runs too hot for too long, it is not just a minor inconvenience. This sustained thermal stress can lead to noticeable performance issues and even permanent damage, which is unacceptable for critical medical tasks.

Prolonged overheating in medical monitors can lead to degraded image quality such as reduced brightness or flickering, slowed system response times, and in severe cases, permanent damage to internal circuitry, potentially compromising diagnostic accuracy or surgical imaging.

Sustained overheating poses several significant risks to the performance and longevity of medical monitors. One of the first noticeable effects can be on image quality13. Excessive heat can cause the brightness of the display to become uneven or generally decrease. Color accuracy might drift, and some users may experience image artifacts like flickering, shimmering, or "image retention" where faint outlines of previous images persist. The display’s response time might also suffer, leading to motion blur or a laggy interface, which is particularly problematic for dynamic imaging modalities.

Beyond these visual degradations, prolonged exposure to high temperatures accelerates the aging of electronic components14. The delicate circuitry within the display, including processors, memory chips, and capacitors, can be permanently damaged. This can lead to intermittent failures, system instability, or complete device failure. For a medical monitor used in diagnostics or surgery, such failures are not merely inconvenient; they can directly impact patient care by providing inaccurate visual information or becoming unavailable during a critical procedure. Therefore, preventing overheating15 is essential for maintaining both the functional integrity and the safety profile of the medical display.

How does Reshin ensure thermal stability in its display products?

Ensuring a display remains stable and reliable even after many hours of continuous operation requires a deliberate engineering focus. We employ several strategies to manage heat effectively within our products.

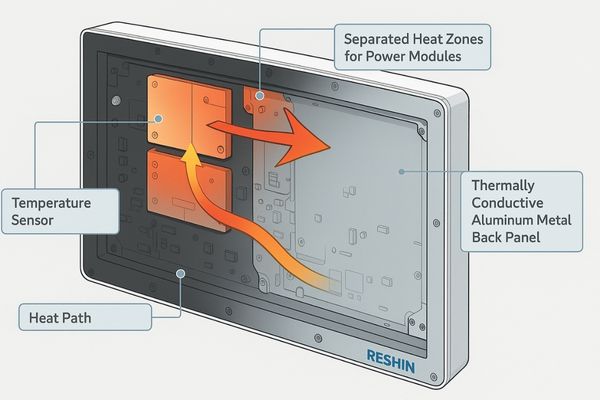

We ensure thermal stability in our MS and MD series displays by implementing multi-point temperature monitoring, creating separate heat zones for power modules, and utilizing thermally efficient metal back panels to optimize passive heat dissipation for consistent long-term performance.

We prioritize thermal stability16 in our display designs, particularly for our MS surgical displays and MD diagnostic monitors, which are often subjected to continuous use. Our approach is multi-faceted. Firstly, we incorporate robust passive cooling solutions17. This typically involves using high-quality, thermally conductive materials, such as aluminum alloys, for the rear chassis or specific internal structural components. These materials act as large heat sinks, drawing heat away from critical internal electronics and dissipating it efficiently into the ambient environment.

Secondly, we pay close attention to the internal layout. Heat-generating components, especially the power supply unit, are often isolated or strategically positioned to prevent their heat from overly affecting other sensitive electronics like the main processing board or the LCD panel itself. This creation of "heat zones[^318]" helps manage thermal loads more effectively. Some designs may incorporate internal temperature sensors at multiple points. While our primary goal is passive dissipation to prevent issues, such sensors could theoretically allow the system to make minor adjustments if an unexpected thermal situation arose, though our designs aim to avoid this necessity through superior passive cooling. This meticulous attention to thermal engineering ensures our displays, like the MS and MD series, can operate for extended periods, often well beyond 12 continuous hours, without performance degradation or risk of overheating, maintaining image stability and component longevity.

Conclusion

Avoiding overheating in continuous-use displays relies on thoughtful design, appropriate cooling methods, and understanding operational risks. This ensures reliable performance for critical medical tasks and prolongs device lifespan. To learn about Reshin’s advanced thermal management in medical displays, contact us at martin@reshinmonitors.com.

-

Understanding the challenges faced by medical displays can help improve their design and functionality, ensuring better patient care. ↩

-

Exploring different cooling systems can provide insights into effective thermal management solutions for medical technology. ↩

-

Learning about thermal stability in medical devices is crucial for ensuring their reliability and safety in critical environments. ↩

-

Understanding the heat generation in LCD panels can help in designing better cooling solutions for medical displays. ↩

-

Exploring the thermal characteristics of LEDs can provide insights into improving display efficiency and longevity. ↩

-

Learning about the power supply’s impact on heat can guide better design choices for reliable medical display systems. ↩

-

Understanding thermal management is crucial for optimizing display performance and longevity. Explore this resource for in-depth insights. ↩

-

Aluminum chassis enhance heat dissipation. Learn why they are favored in electronic design for better performance. ↩

-

Heat sinks are vital for cooling components. Discover how they function and their importance in device design. ↩

-

Understanding the pros and cons of Active Cooling can help you choose the right system for your needs, especially in sensitive environments. ↩

-

Exploring the benefits of Passive Cooling can reveal why it’s often favored in medical settings for its reliability and silent operation. ↩

-

Learning about heat dissipation mechanisms can enhance your knowledge of thermal management in electronics, crucial for performance and longevity. ↩

-

Understanding the factors that influence image quality can help ensure optimal performance and patient safety in medical settings. ↩

-

Exploring this topic reveals the critical impact of temperature on device reliability and longevity, essential for patient care. ↩

-

Learning about prevention strategies can enhance the lifespan and reliability of medical monitors, crucial for accurate diagnostics. ↩

-

Understanding thermal stability is crucial for ensuring the longevity and performance of displays, especially in demanding environments. Explore this link for in-depth insights. ↩

-

Passive cooling solutions are essential for maintaining optimal performance in electronics. Discover various methods and their benefits by exploring this resource. ↩