Diagnostic monitors are essential for accurate medical judgments. Their unexpected failure can disrupt critical healthcare workflows. What causes these vital tools to malfunction?

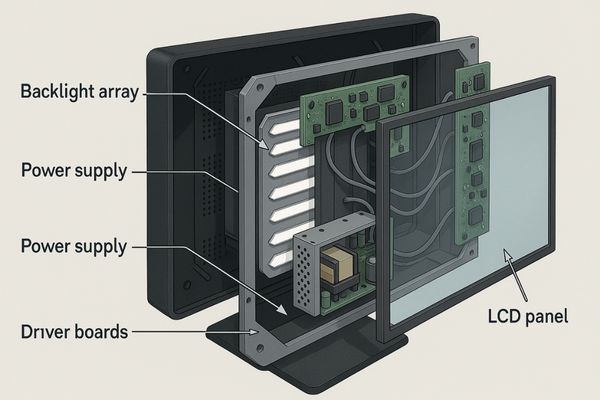

The main failure points in diagnostic monitors often involve the backlight system, power supply units, and LCD panels due to heat, prolonged use, and electrical stress. Understanding these vulnerabilities helps maintain diagnostic accuracy and monitor longevity.

The reliability of a diagnostic monitor is not just a matter of convenience; it is a cornerstone of patient safety and effective diagnosis. In this article, I will delve into the common issues that can lead to monitor failure. We will explore the vulnerable components, the impact of usage patterns, and environmental influences. Understanding these aspects is key to ensuring consistent performance.

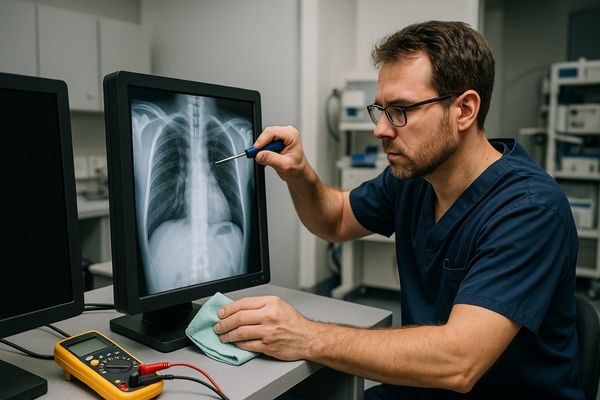

Which components are most vulnerable in diagnostic-grade monitors?

Radiologists depend on consistently clear images for their work. When a component fails, this clarity is lost. Which parts of a diagnostic monitor are most prone to issues?

The most vulnerable components in diagnostic-grade monitors are often the backlight system (especially LEDs), power supply units (PSUs), LCD driver integrated circuits (ICs), and image processing boards. These parts are sensitive to heat, electrical stress, and aging.

Several key components within a diagnostic monitor bear the brunt of continuous operation and are therefore more susceptible to failure. The backlight system1, typically composed of LEDs in modern displays, is critical for illuminating the screen. These LEDs can degrade over time, especially under high brightness settings, leading to dimming or uneven illumination. Power supply units2 convert AC power to the DC voltages needed by the monitor’s internal circuitry. PSUs are vulnerable to power surges, fluctuations, and component aging, particularly capacitors, which can lead to complete monitor failure or intermittent issues. LCD driver ICs3, responsible for controlling the individual pixels on the screen, can fail due to electrical stress or manufacturing defects, resulting in dead pixels, lines on the screen, or incorrect image display. Finally, the image processing boards, which handle tasks like DICOM calibration and image enhancement, contain complex circuitry that can be affected by heat and electrical instability. These components often work hard, generating heat, which if not managed, accelerates their degradation.

Common Points of Failure

Understanding these specific vulnerabilities helps in maintenance and design.

- Backlight Units: LEDs have a finite lifespan. Prolonged use, especially at high brightness levels, shortens this.

- Power Modules: These components handle significant electrical loads. They are sensitive to input power quality and internal heat buildup.

- LCD Driver ICs: These delicate circuits control the pixel array. They can be damaged by electrostatic discharge or thermal stress.

- Image Processors: These complex boards manage image data. Overheating or component failure can lead to various display artifacts.

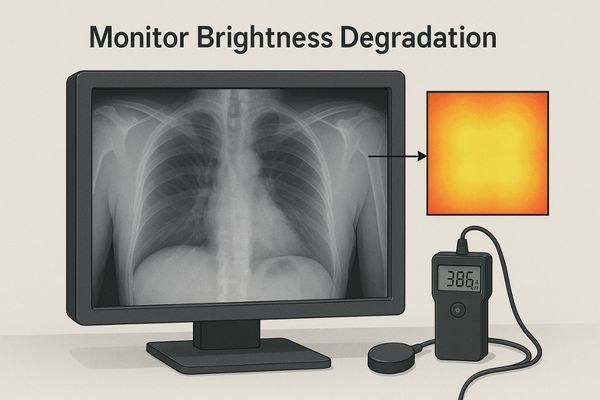

How does prolonged high-brightness usage affect performance?

Bright screens are essential for viewing subtle details in medical images. This constant demand for high luminance must have some effect. How does it impact the monitor’s performance over its lifespan?

Prolonged high-brightness usage accelerates the degradation of the LED backlight system. This leads to reduced overall luminance, non-uniform brightness across the screen, and potential color shifts, compromising DICOM compliance and image quality.

Diagnostic monitors, particularly those used for mammography or chest X-rays, are often operated at very high brightness levels to ensure subtle pathologies are visible. While this is necessary for diagnostic accuracy, it places significant stress on the backlight system, typically comprised of Light Emitting Diodes (LEDs)4. Continuous operation at peak brightness generates more heat and drives the LEDs harder, accelerating their natural degradation process. This degradation manifests in several ways. Firstly, the overall maximum luminance the monitor can achieve decreases over time. Secondly, brightness uniformity5 across the screen can suffer. Some areas may become dimmer than others as individual LEDs or groups of LEDs age at different rates. This non-uniformity can make it difficult to compare image densities across different parts of an image. Thirdly, color shifts can occur as the spectral output of the LEDs changes with age. This can affect the accurate representation of color images if the monitor is used for multi-modality viewing. Ultimately, these changes can lead to the monitor falling out of compliance with DICOM Part 14 standards6, which are crucial for consistent medical image display.

Consequences of Backlight Degradation

The effects extend beyond just a dimmer screen.

- Reduced Luminance: The screen’s maximum brightness capability diminishes over time.

- Luminance Non-Uniformity: Brightness variations appear across the display surface.

- Color Shifts: The color temperature and accuracy can change, affecting image fidelity.

- DICOM Non-Compliance: The monitor may no longer meet the grayscale display standards required for medical diagnosis.

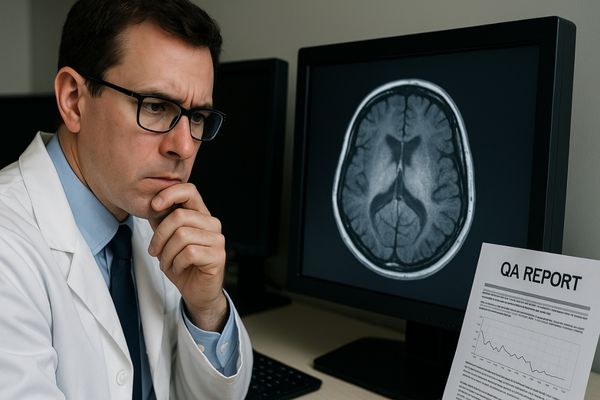

Can calibration drift lead to clinical image misinterpretation?

Accurate diagnosis relies on images being displayed consistently. If a monitor’s calibration settings change over time, crucial details could be missed. Can this drift result in significant diagnostic errors?

Yes, calibration drift can absolutely lead to clinical image misinterpretation. An uncalibrated monitor may not accurately display grayscale values, potentially obscuring subtle pathologies or misrepresenting lesion characteristics, thereby affecting diagnostic decisions.

Diagnostic monitors are calibrated to a specific standard, most commonly the DICOM Part 14 Grayscale Standard Display Function (GSDF)7. This standard ensures that differences in pixel values in a medical image correspond to perceptually linear changes in displayed luminance. In simple terms, it ensures that shades of gray are displayed correctly and consistently, allowing radiologists to accurately perceive subtle variations in tissue density. However, over time, due to factors like backlight aging and electronic component drift, a monitor’s grayscale response can deviate from this calibrated state. This is known as calibration drift8. When drift occurs, the monitor may no longer display the full range of grayscale values accurately. For example, subtle low-contrast lesions or the fine edges of a tumor might become less distinct or even invisible if the monitor’s dark grays are too bright or its light grays are not bright enough. This is particularly critical in modalities like mammography, where detecting tiny microcalcifications depends on precise grayscale rendition, or in chest radiography for spotting faint lung nodules. Regular quality assurance and recalibration9 are essential to counteract this drift and maintain diagnostic integrity. Failure to do so risks misdiagnosis or delayed diagnosis.

What environmental factors accelerate diagnostic monitor failure?

Diagnostic monitors often operate in busy, demanding clinical settings. The environment itself can present hidden challenges. What specific conditions can negatively impact a monitor’s durability and lead to premature failure?

Environmental factors like high ambient temperature, humidity, dust accumulation, unstable power supply (surges or dips), and poor ventilation significantly accelerate diagnostic monitor failure by causing overheating and component stress.

The environment in which a diagnostic monitor operates plays a significant role in its longevity and reliability. Several factors can accelerate wear and tear, leading to premature failure. High ambient temperatures in a reading room, often exacerbated by multiple heat-generating workstations and poor air circulation, can cause internal monitor temperatures to rise. This excess heat stresses electronic components, speeding up their degradation. Humidity is another concern. High humidity10 can lead to condensation on internal circuit boards, potentially causing short circuits or corrosion over time. Dust is a pervasive enemy in many environments. It can accumulate inside the monitor, clogging ventilation pathways and acting as an insulator on components. This traps heat and further contributes to overheating. An unstable power supply, characterized by voltage spikes, sags, or frequent interruptions, can damage sensitive power supply units and other electronic components. Finally, poor ventilation11 around the monitor itself, such as placing it too close to a wall or in a confined space, prevents effective heat dissipation, leading to higher internal operating temperatures. Managing these environmental factors through proper room design, air conditioning, dust control, and use of uninterruptible power supplies (UPS) is crucial for maximizing monitor lifespan.

Key Environmental Stressors and Their Impact

| Environmental Factor | Impact on Monitor |

|---|---|

| High Ambient Temperature | Increases internal operating temperature, accelerates component aging. |

| High Humidity | Risk of condensation, corrosion, and short circuits on internal electronics. |

| Dust Accumulation | Clogs vents, insulates components, leads to overheating, can cause short circuits. |

| Unstable Power Supply | Damages power supply unit and other sensitive electronics through surges or sags. |

| Poor Ventilation | Prevents effective heat dissipation, leading to increased internal temperatures. |

Addressing these environmental factors is a key part of a good maintenance strategy for any facility relying on diagnostic displays.

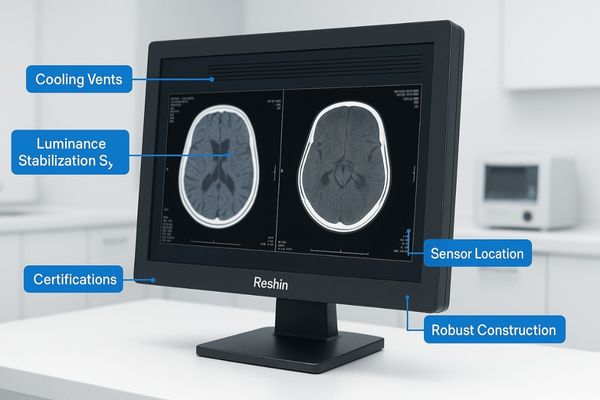

How does Reshin enhance the reliability of its diagnostic display systems?

Ensuring that diagnostic monitors last and perform consistently is vital for healthcare facilities. Frequent breakdowns are not just costly but also disruptive to patient care. How do we design our displays to endure these challenges?

Reshin enhances diagnostic display reliability by incorporating features such as automatic luminance stabilization, robust circuit protection against power fluctuations, and advanced thermal management systems. These ensure consistent performance and extended lifespan under demanding workloads.

At Reshin, we focus on building robust diagnostic display systems designed for longevity and stable performance, even under intensive daily use. We achieve this through several key design philosophies and incorporated technologies. For instance, many of our MD-series monitors, like the MD120C 12MP High-Precision Diagnostic Monitor, feature automatic luminance compensation12 or stabilization. This typically involves an integrated front sensor that continuously monitors the screen’s brightness and adjusts the backlight output to maintain consistent luminance levels over time, compensating for LED aging and warm-up characteristics. This ensures stable DICOM compliance. We also implement robust circuit protection mechanisms within our power supply units and other critical boards. These are designed to safeguard the monitor against common electrical issues such as voltage spikes or brownouts, which can be prevalent in some healthcare facility power grids. Furthermore, active thermal management13 is a cornerstone of our design. This includes strategically placed heat sinks, optimized internal airflow pathways, and sometimes low-noise fans to efficiently dissipate heat generated by the backlight and other electronics. By keeping internal components cooler, we significantly reduce thermal stress and prolong their operational life. These measures collectively contribute to ensuring our monitors, provide reliable service for over 5+ years, supporting clinicians in their critical diagnostic tasks.

Conclusion

Understanding common failure points such as backlight wear, power issues, and environmental stress helps maintain monitor reliability. This knowledge ensures consistent diagnostic accuracy and extends the life of these vital medical tools. For reliable medical displays engineered to withstand clinical challenges, contact Reshin at martin@reshinmonitors.com.

-

Understanding the backlight system’s role can help you maintain optimal display performance and longevity. ↩

-

Learn how PSUs impact monitor reliability and how to protect them from failures. ↩

-

Explore the challenges faced by LCD driver ICs to better understand monitor display problems. ↩

-

Learning about LEDs in diagnostic monitors helps understand their role in image quality and longevity, important for healthcare technology. ↩

-

Exploring brightness uniformity can reveal its impact on diagnostic accuracy and image quality, vital for medical professionals. ↩

-

Understanding DICOM Part 14 standards is essential for ensuring compliance in medical imaging, which is crucial for accurate diagnoses. ↩

-

Understanding GSDF is crucial for ensuring accurate medical imaging and diagnosis. Explore this link to learn more about its importance. ↩

-

Learn about calibration drift to understand its impact on medical imaging accuracy and the importance of regular recalibration. ↩

-

Discover the significance of quality assurance and recalibration in maintaining diagnostic integrity and preventing misdiagnosis. ↩

-

Exploring the effects of humidity on electronics can guide you in creating a safer environment for your diagnostic monitors. ↩

-

Learning about the risks of poor ventilation can help you implement better practices to enhance the lifespan of your monitors. ↩

-

Learn about automatic luminance compensation to see how it maintains consistent image quality in medical displays. ↩

-

Discover the importance of active thermal management in prolonging the life of electronic devices and ensuring optimal performance. ↩