Hospitals demand clear imaging without energy waste. Unchecked power use strains budgets and heats equipment. I apply layered strategies to keep surgical displays efficient, safe, and clinically reliable.

This article maps practical power management for surgical displays: adaptive brightness, standby, efficient PSUs, thermal design, and intelligent scheduling. I connect engineering choices to OR workflow, reliability, and sustainability outcomes.

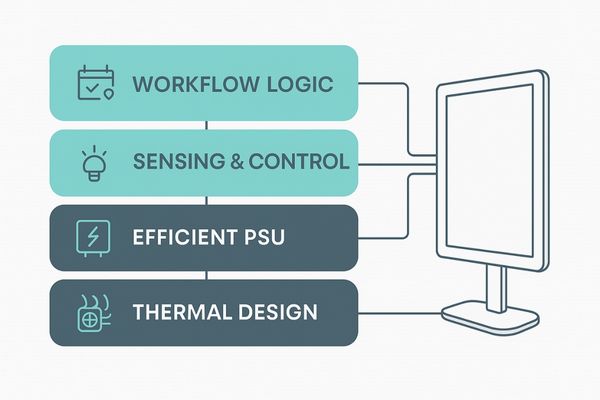

A modern https://reshinmonitors.com/top-medical-display-manufacturers-2025/1 must deliver consistent luminance, color stability, and fail-safe behavior while consuming as little energy as the task allows. That balance depends on context-aware controls, robust electronics, and predictable thermal behavior. I structure power management2 as a stack: sensing and control at the top, conversion efficiency in the middle, and heat flow at the bottom. Above that stack sits workflow logic, which ensures the screen is active only when the team needs it. One practical reference point is the compact surgical platform represented by MS192SA, which highlights how right-sized panels, calibrated luminance targets, and guarded standby states reduce total energy without sacrificing detail. Clear policies matter as much as hardware. The team gains confidence when displays wake instantly, preserve calibration, and never throttle mid-procedure. With the right instrumentation—ambient light sensors, internal power telemetry, and thermal probes—we can tune settings to room conditions and case type, cutting waste while protecting image integrity.

Strategy-versus-impact snapshot

| Strategy | Typical energy reduction | Primary clinical impact |

|---|---|---|

| Adaptive brightness | 10–35% | Stable visibility, less glare |

| Low-power standby | 60–95% (idle periods) | Lower thermal stress |

| High-efficiency PSU | 5–12% | Less heat, higher reliability |

| Optimized thermal path | 3–10% | Steady luminance over time |

| Intelligent scheduling | 10–25% (per day) | Fewer distractions, readiness |

Adaptive brightness control reduces unnecessary power consumption

Bright screens ensure precision, yet fixed maximum luminance wastes power. Excess brightness also increases glare and eye fatigue. Adaptive control senses ambient light and content, then delivers the minimum safe luminance.

Adaptive brightness aligns luminance to ambient conditions and content. The method preserves contrast, limits glare, and reduces backlight load. The result is stable visibility with meaningful power savings across diverse surgical lighting scenarios.

Adaptive brightness works when sensors, control loops, and calibration agree on a target. OR lights vary by case phase, so the display must update luminance smoothly and predictably. A good controller filters sensor noise, respects minimum luminance floors, and preserves grayscale tracking. The backlight driver should modulate in small steps to avoid pumping or flicker during endoscopic scenes with rapidly changing average picture level. In surgical use, reliable visibility beats raw brightness. We bind targets to clinical tasks: higher during incision and suturing, lower during positioning and documentation. A well-tuned curve limits glare, reduces eye strain, and improves camera dynamic range perception. The backlight ages more slowly because it runs cooler, and power draw drops during long, quiet phases of a case. Color accuracy remains intact when dimming is paired with gamma compensation and white-point maintenance. A surgical display3 like MS220SA exemplifies this approach with responsive control that prioritizes clarity over brute-force luminance.

Low-power standby modes extend component lifespan

Displays often idle between cases. Idle power wastes electricity and cooks components. Simple power-off is too slow for busy rooms. Smart standby keeps readiness while shrinking thermal and electrical stress.

Well-designed standby drops consumption to fractions of active power, preserves calibration data, and resumes in seconds. The approach cuts heat cycles, extends component life, and supports tight OR turnaround times.

Standby design must segment the system into always-on and switchable domains. The always-on microcontroller4 listens for wake triggers from the OR tower, video signal, or staff console. The panel power, backlight, and high-load logic rails shut down. This topology slashes idle draw while keeping control logic alert. Resume must be fast: surgeons expect a live image within a few seconds, with reference luminance ready and color stable. To prevent thermal shock, soft-start current limiting and staged rail sequencing protect capacitors and LEDs. We also store calibration in non-volatile memory and verify it on wake without lengthy warm-up. For infection control, front glass heaters, if present, should remain off in standby unless humidity demands minimal anti-fog support. Policies matter: an auto-standby5 after no-signal helps at night, while manual hold is safer during brief turnovers. Over months, reduced hot-soak time lengthens LED backlight life and slows electrolyte evaporation in capacitors. A responsive platform like MS247SA demonstrates these standby priorities in daily OR use.

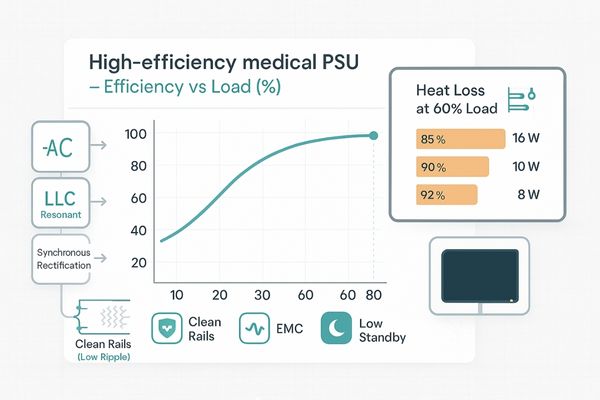

Efficient power supplies improve energy conversion rates

Inefficient power conversion turns watts into heat. Extra heat prompts fan activity, noise, and earlier component aging. High-efficiency medical PSUs reduce losses and stabilize thermal behavior under variable video loads.

Raising PSU efficiency from mid-80s to low-90s trims waste heat, shrinks acoustic noise, and improves reliability. Tighter regulation also prevents luminance drift when scenes or peripherals change the system load.

The power supply sets the floor for energy performance. Medical-grade designs must meet IEC 606016 safety, leakage, and EMC requirements while still achieving high efficiency at realistic loads. OR usage rarely pins maximum power; typical loads sit near 30–60% of PSU rating. That range must be the optimization target. Low standby draw, synchronous rectification7, and resonant topologies help, but firmware plays a role by coordinating panel dimming, signal processing, and USB power budgeting. Less dissipation means cooler operation, which raises component mean time between failures and stabilizes luminance because the LED backlight and LCD optics drift less with temperature. Ripple and transient response matter for image stability; clean rails prevent artifacts when endoscopic light sources modulate intensity. Selecting an efficient platform such as MS270P showcases how small percentage gains translate into meaningful temperature drops and quieter cooling. Over a year of continuous duty, a few watts saved per unit becomes significant energy and cost reduction.

Efficiency-to-loss reference (typical 150 W max, 60% load)

| PSU efficiency | Input power | Output power | Power lost as heat |

|---|---|---|---|

| 85% | 106 W | 90 W | 16 W |

| 90% | 100 W | 90 W | 10 W |

| 92% | 98 W | 90 W | 8 W |

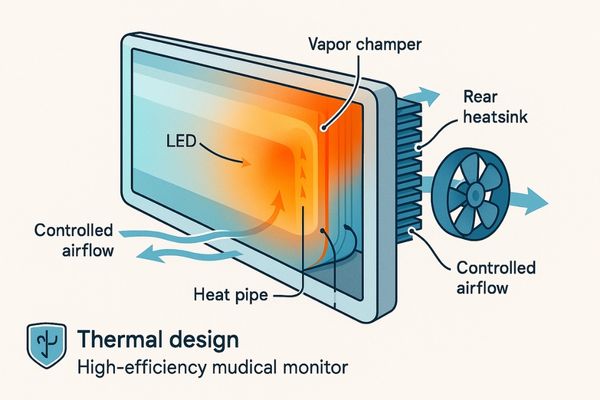

Thermal management impacts overall energy efficiency

Poor heat flow raises panel temperature and increases leakage, LED forward voltage spread, and fan duty. Hot spots also age components faster. Good thermal paths reduce electrical loss and keep images consistent.

Thermal design is energy design. Lower junction temperatures cut resistive loss, allow quieter fans, and maintain calibrated luminance. The display stays reliable through long cases, even under bright OR lights.

Thermal strategy begins with mapping heat sources: backlight drivers, scalar SoCs, and power converters. We route heat to the chassis with heat pipes8 or vapor chambers, then to ambient air with controlled convection. When fans are necessary, large, slow impellers beat small, fast ones for acoustic comfort and efficiency. Intelligent fan curves consider inlet air temperature and dust load, limiting unnecessary RPM spikes that consume power and distract staff. Lower die temperature reduces leakage currents and keeps LED output uniform, which stabilizes calibration. Every ten degrees of temperature rise can roughly double certain failure rates, so heat is reliability’s enemy. Sealed fronts for splash resistance complicate airflow; side channels and rear sinks must compensate without pulling contamination toward sterile zones. The design must keep hands-safe surface temperatures while avoiding thermal throttling of image processing during 4K video. A platform exemplified by MS321PB shows how robust heat paths sustain luminance targets without racing fans or wasteful headroom.

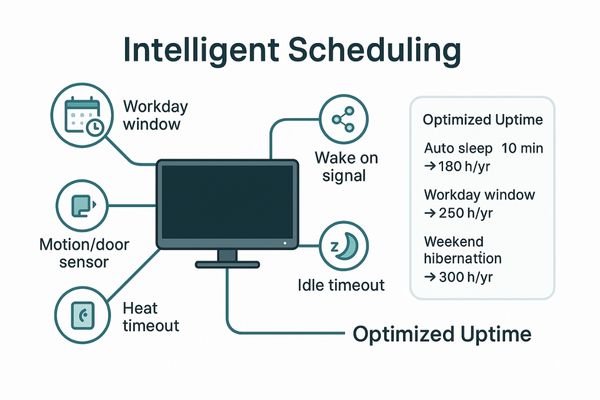

Intelligent scheduling optimizes display uptime and downtime

Many screens run longer than needed due to habits and fear of delays. Unscheduled runtime wastes power and shortens life. Smart schedules align operation with clinical rhythms without risking readiness.

Schedules enforce discipline without friction. Signal-based wake, calendar rules, and motion or door sensors cut idle hours, protect components, and keep teams confident that displays are ready exactly when needed.

Scheduling succeeds when automation is trustworthy and transparent. The display should wake on video presence from the endoscopic tower, on network commands from the OR system, or at set times before cases start. It should sleep after defined idle periods, yet avoid nuisance offs during brief pauses. A human override must be simple and logged. When several rooms share equipment, fleet policies prevent drift in settings across devices. Analytics reveal daily patterns so we can tailor schedules to specialties that operate late or have rapid turnovers. Integrating with building systems enables night setbacks and weekend hibernation while preserving security updates. Staff training focuses on what not to worry about; predictability reduces workaround behavior. Over months, reduced runtime lowers cumulative heat exposure and preserves backlight output. A scheduling-aware display9 such as MS321PB demonstrates that the best energy savings rarely require a single compromise to workflow or image quality.

Example schedule outcomes (per display, typical OR)

| Policy | Setting | Annual runtime saved | Energy saved (kWh) |

|---|---|---|---|

| Auto sleep on no-signal | 10 minutes | 180 hours | 54 |

| Workday calendar | 07:00–19:00 active window | 250 hours | 75 |

| Weekend hibernation | Saturday–Sunday deep sleep | 300 hours | 90 |

Efficient power supplies improve energy conversion rates

Inefficient power conversion turns watts into heat. Extra heat prompts fan activity, noise, and earlier component aging. High-efficiency medical PSUs reduce losses and stabilize thermal behavior under variable video loads.

Raising PSU efficiency from mid-80s to low-90s trims waste heat, shrinks acoustic noise, and improves reliability. Tighter regulation also prevents luminance drift when scenes or peripherals change the system load.

The power supply sets the floor for energy performance. Medical-grade designs must meet IEC 6060110 safety, leakage, and EMC requirements while still achieving high efficiency at realistic loads. OR usage rarely pins maximum power; typical loads sit near 30–60% of PSU rating. That range must be the optimization target. Low standby draw, synchronous rectification11, and resonant topologies help, but firmware plays a role by coordinating panel dimming, signal processing, and USB power budgeting. Less dissipation means cooler operation, which raises component mean time between failures and stabilizes luminance because the LED backlight and LCD optics drift less with temperature. Ripple and transient response matter for image stability; clean rails prevent artifacts when endoscopic light sources modulate intensity. Selecting an efficient platform such as MS270P showcases how small percentage gains translate into meaningful temperature drops and quieter cooling. Over a year of continuous duty, a few watts saved per unit becomes significant energy and cost reduction.

Efficiency-to-loss reference (typical 150 W max, 60% load)

| PSU efficiency | Input power | Output power | Power lost as heat |

|---|---|---|---|

| 85% | 106 W | 90 W | 16 W |

| 90% | 100 W | 90 W | 10 W |

| 92% | 98 W | 90 W | 8 W |

Reshin integrates eco-friendly power management into product design

Hospitals want greener ORs without compromising image quality. Disconnected features do not add up. Integrated design bakes efficiency into optics, electronics, firmware, and workflow from the first sketch.

Reshin approaches power holistically: adaptive controls, efficient PSUs, thoughtful thermals, and automation. The design reduces energy, heat, and noise, while supporting long life and consistent clinical performance across procedures.

Eco-friendly design12 begins with requirements that value lifecycle outcomes. We target aggressive efficiency at realistic loads, specify recyclable materials where possible, and favor serviceable assemblies that extend product life. Firmware exposes clear power profiles for day, night, and deep-clean periods. Integration with OR towers ensures instant wake on signal while respecting strict standby limits at other times. Thermal solutions aim for passive-first, fans-second, because quiet rooms help concentration and save watts. Calibration stability under varying temperatures preserves image trust without forcing higher-than-needed backlight duty. Fleet tools propagate schedules and policy updates, so gains scale across all rooms. Documentation quantifies savings to support sustainability reports and regulatory needs. When hospitals measure total cost of ownership13, lower energy, fewer replacements, and shorter downtime matter as much as purchase price. A 55-inch class surgical platform like MS550P shows how these choices converge into a dependable, efficient, and environmentally considerate display fleet.

Conclusion

Thoughtful power management—controls, conversion, cooling, and scheduling—delivers reliable images, longer life, quieter rooms, and measurable energy savings without compromising surgical performance.

📩 Want medical displays with advanced power management features? Contact Martin at martin@reshinmonitors.com to learn more about Reshin’s energy-efficient solutions.

- Explore this link to understand the essential features and technologies that enhance surgical displays for better performance. ↩

- Learn about the intricacies of power management in surgical displays and how it impacts efficiency and performance. ↩

- Exploring surgical display features can help you appreciate the technology that improves visibility and precision in medical environments. ↩

- Explore this link to understand how always-on microcontrollers enhance system efficiency and responsiveness. ↩

- Learn about auto-standby features and their role in energy conservation and device longevity. ↩

- Understanding IEC 60601 is crucial for ensuring compliance and safety in medical device design, making this resource invaluable. ↩

- Exploring synchronous rectification can enhance your knowledge of power supply design, leading to better efficiency and performance. ↩

- Exploring heat pipes can enhance your knowledge of efficient thermal management solutions, vital for electronics and engineering. ↩

- Explore this link to understand how scheduling-aware displays enhance efficiency and energy savings in medical environments. ↩

- Understanding IEC 60601 is crucial for compliance in medical device design, ensuring safety and reliability. ↩

- Exploring synchronous rectification reveals its benefits in enhancing power supply efficiency, crucial for energy-saving designs. ↩

- Exploring this resource will provide insights into how eco-friendly design can enhance sustainability and efficiency in products. ↩

- Understanding total cost of ownership is crucial for making informed decisions in healthcare investments, ensuring long-term savings and efficiency. ↩