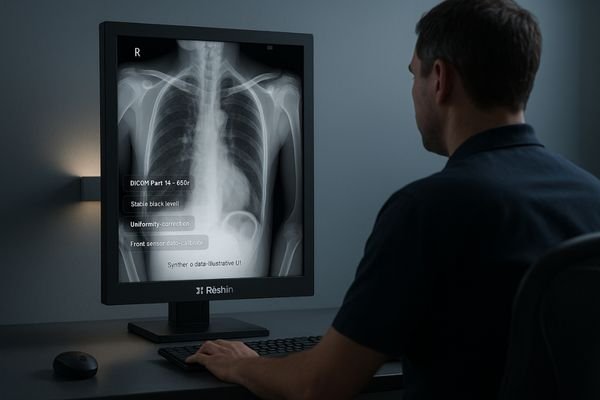

Using a non-compliant display for medical imaging can distort grayscale tones, leading to missed diagnoses. This inconsistency across workstations puts diagnostic confidence and patient safety at risk.

Prioritize GSDF-accurate luminance, stable black level, and screen-wide uniformity on any DICOM Part 14 monitor. Front-sensor auto-calibration, TG-18 constancy reports, and AR-bonded glass preserve micro-contrast; sRGB/BT.709 fidelity keeps overlays true. Choose medical DICOM displays with centralized QA for fleet consistency.

Recommended models

Choosing the right diagnostic monitor is not about chasing the highest resolution or largest size. Instead, the decision must be grounded in clinical risk reduction1. The cornerstone of a reliable medical display is its adherence to the DICOM Part 14 standard2. This ensures that every grayscale value is rendered predictably, providing a stable and consistent foundation for every interpretation. This article breaks down the essential technical and workflow criteria that define a truly effective diagnostic monitor, moving beyond marketing claims to focus on what delivers tangible clinical value.

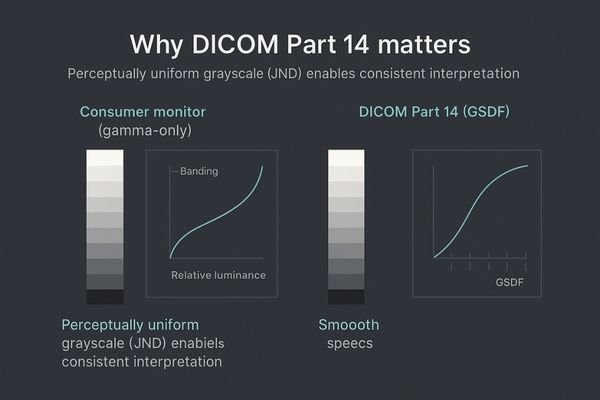

Why DICOM Part 14 Matters for Diagnostic Confidence

A standard office monitor might look sharp, but it can subtly distort contrast gradients. This alters detection thresholds and makes follow-up comparisons unreliable, creating diagnostic uncertainty.

DICOM Part 14 maps luminance to the GSDF curve, making each grayscale step perceptually uniform. This single capability ensures consistent image interpretation across rooms, readers, and time, underpinning all diagnostic confidence.

The Grayscale Standard Display Function (GSDF)3 is the core principle of DICOM Part 14. Its purpose is to ensure that the relationship between the digital value in an image file and the luminance produced by the screen is standardized and perceptually linear. This means that for every step up in the grayscale value, a viewer perceives an equal step up in brightness, also known as a Just Noticeable Difference (JND). This consistency is mission-critical. When a radiologist performs a window/level adjustment, the behavior must be identical whether they are at their primary workstation, in a consult room, or reviewing a study from home. This uniformity ensures that subtle, low-contrast findings remain visible regardless of the display used. Using a monitor like the MD22CA guarantees this baseline consistency, forming the shortest path to fewer rescans, faster consensus in multi-disciplinary teams (MDTs), and an auditable trail of image quality. This is why DICOM compliance4 must be the first filter in any procurement process.

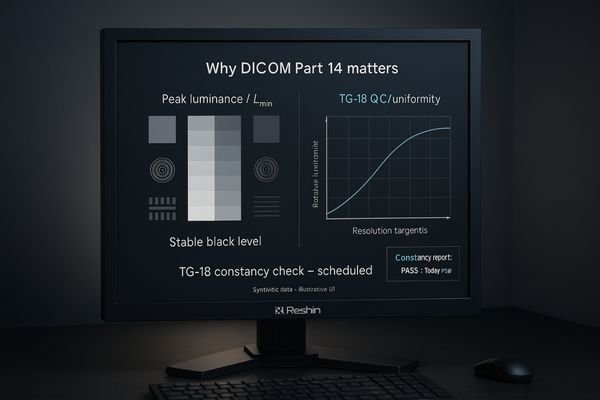

Luminance, Uniformity, and AAPM TG-18 Practical Verification Workflow

A monitor might be DICOM compliant at its center, but what about the corners? Peak luminance, black level, and spatial uniformity all determine if GSDF is delivered consistently across the entire screen.

A practical workflow using AAPM TG-18 test patterns verifies real-world performance. This ensures stable black levels, adequate luminance, and screen-wide uniformity, preventing diagnostic bias and reducing quality assurance labor.

The American Association of Physicists in Medicine (AAPM) Task Group 18 (TG-18) provides a set of standardized test patterns and procedures for evaluating display performance5. This framework translates theoretical compliance into a practical, repeatable verification workflow. The process is straightforward: measure key metrics, compare them to established limits, correct any deviations, and log the results. High-quality diagnostic displays integrate this process. For instance, built-in front sensors on a monitor like the MD26GA can automate these TG-18 constancy checks6, measuring luminance and color at scheduled intervals without human intervention. This ensures stable black levels, which prevent low-contrast details from being "washed out," and guarantees screen-wide uniformity, which eliminates the risk of a lung nodule or brain lesion being missed simply because it appeared in a dimmer corner of the screen. In 2025, this verification must be automated and report-driven. If a quality check is not logged, for all practical purposes, it never happened.

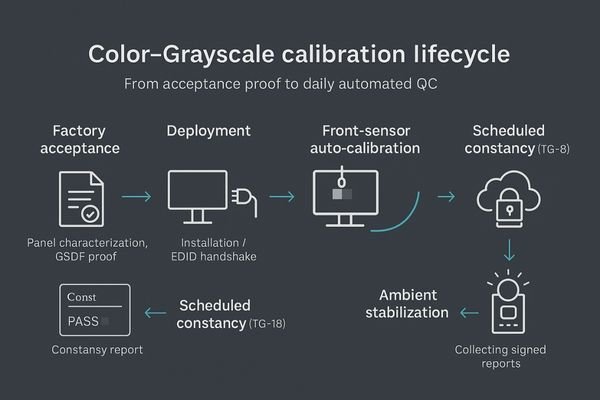

Color–Grayscale Calibration: From Factory Acceptance to Daily QC

Calibration is not a one-time event; it is a continuous lifecycle. A monitor that is perfect out of the box can drift over time, slowly eroding the consistency that DICOM promises.

Effective calibration begins with factory acceptance proof and continues with automated daily self-calibration and constancy checks. This lifecycle approach ensures every reader at every workstation sees the exact same image, day or night.

A trustworthy diagnostic monitor must manage its own calibration throughout its entire lifespan. The process starts at the factory, with detailed characterization of the LCD panel and proof of GSDF conformance. Once deployed, the monitor must maintain this standard. The best solution for this is an integrated front sensor that performs automated self-calibration7, along with internal sensors that stabilize backlight output. Together, these systems perform scheduled constancy checks, tracking performance and issuing signed reports that can be managed centrally by a physics team. For modern multi-modality radiology, this must extend beyond grayscale. The MD32C is an example of a monitor that pairs its DICOM calibration8 with accurate color representation for standards like sRGB, ensuring that clinical photos or color-coded overlays are rendered faithfully. This comprehensive, automated approach changes behavior: radiologists trust the display, and physicists can proactively manage performance drift before it ever becomes a clinical issue.

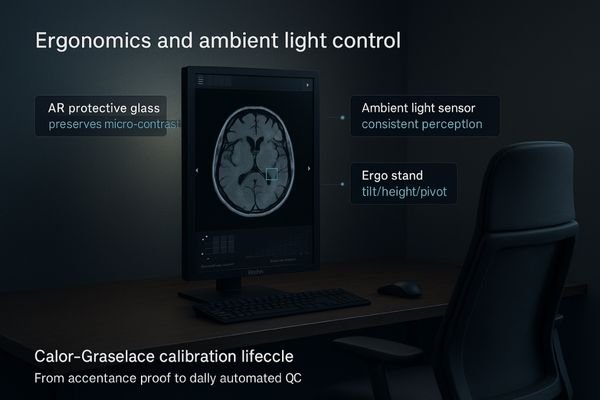

Ambient Light Control, AR Glass, and Reading Ergonomics

A perfectly calibrated monitor can be defeated by a poorly controlled reading environment. Reflections from overhead lights or windows can create veiling glare, obscuring subtle but critical details.

Managing the reading environment is part of the display system. A combination of anti-reflection (AR) glass, ambient light sensors, and ergonomic design is crucial for reducing eye strain and maintaining contrast in real-world conditions.

The reading room itself is an integral part of the diagnostic imaging chain. To combat environmental factors, a high-performance diagnostic monitor must incorporate several key features. Anti-reflection (AR) protective glass9 is essential for cutting down glare from ambient light sources without sacrificing the micro-contrast needed to see fine details. When combined with optical bonding, this technology makes the image appear crisp and clear, even in brighter rooms. Furthermore, an integrated ambient light sensor10 allows the monitor to automatically adjust its brightness to maintain a consistent perceptual experience as room conditions change. The physical design also plays a critical role in ergonomics. A monitor with a wide range of height, tilt, and pivot adjustments, like the MD33G, allows radiologists to maintain a neutral posture, reducing fatigue over long reading sessions. These features work together to ensure that low-contrast liver lesions or subtle brain edema remain visible across different shifts and readers.

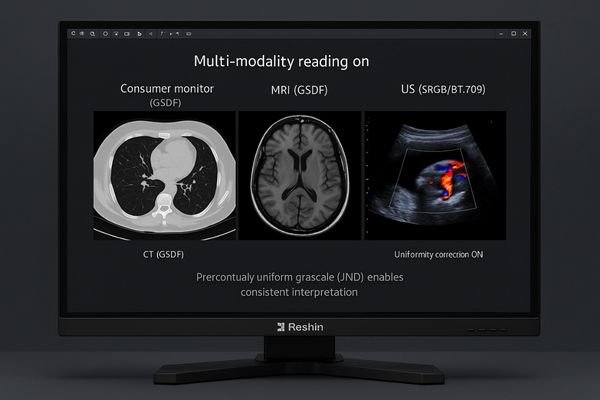

Multi-Modality Reading: CT, MRI, Ultrasound on One Display

Modern radiology departments no longer work in isolated silos. A typical workflow involves comparing grayscale CT and MRI scans alongside color Doppler ultrasound or 3D fusion imaging.

An effective multi-modality medical DICOM display must deliver GSDF-accurate grayscale and faithful color simultaneously. This ensures radiologists can interpret diverse studies on a single desktop without cognitive friction or diagnostic compromise.

To support today’s integrated workflows, a diagnostic monitor must be a versatile performer. It needs to provide a DICOM Part 14 compliant11 grayscale backbone for anatomical imaging while also rendering color spaces like sRGB and BT.70912 accurately for functional and supplemental information. This dual capability allows a radiologist to review a CT angiography study, a PET/CT fusion image, and an ultrasound clip on the same screen, trusting that both the grayscale anatomy and the color data are correct. High-quality displays manage this with sophisticated internal lookup tables (LUTs) and uniformity correction, ensuring that one modality’s color does not compromise another’s grayscale integrity. The practical benefit is a streamlined workflow, especially in tumor boards or on-call scenarios. It speeds up consensus-building and reduces the mental "gear-shifting" required when moving between different types of studies, ultimately leading to a more efficient and reliable diagnostic process.

| Modality | Key Display Requirement | Why It Matters |

|---|---|---|

| CT/MRI/X-Ray | DICOM Part 14 GSDF Compliance | Ensures consistent and accurate representation of grayscale anatomy. |

| Ultrasound | Accurate Color (sRGB/BT.709) | Faithfully renders color Doppler, elastography, and other functional data. |

| PET/SPECT | Hybrid Color/Grayscale | Correctly displays fusion overlays without distorting underlying CT/MRI. |

| PACS/RIS UI | Low Latency & Font Clarity | Provides a responsive user experience for window/level and navigation. |

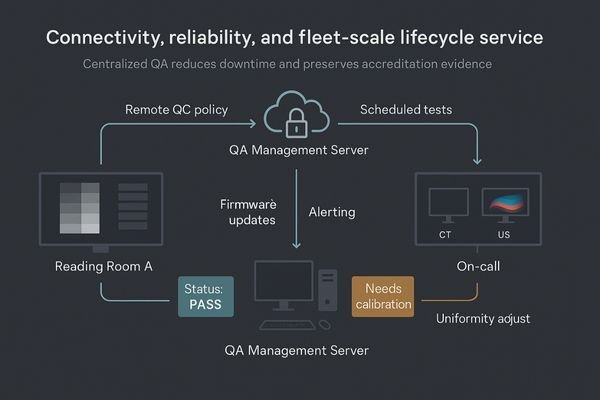

Connectivity, Reliability, and Fleet-Scale Lifecycle Service for Hospitals

Hospitals purchase display fleets, not just single screens. The total cost of ownership is determined by reliability, serviceability, and the ability to manage the entire fleet efficiently.

Long-term value depends on robust connectivity, reliable hardware, and centralized lifecycle management. Features that support remote QC, firmware updates, and fast panel replacement drastically reduce downtime and preserve accreditation evidence.

When deploying diagnostic monitors13 at scale, enterprise-grade features become paramount. At the hardware level, this means reliable power supplies, effective thermal management, and stable panel sourcing to ensure a monitor purchased in 2025 is serviceable in 2028. Connectivity must be robust, with DisplayPort and HDMI ports that handle EDID communication predictably. More importantly, the monitor must be designed for fleet management. This requires a secure network connection (LAN) or USB interface that allows a central quality assurance server to remotely deploy QC policies, schedule tests, run firmware updates, and collect logs. This capability transforms maintenance from a reactive, manual task into a proactive, automated process. It cuts down on the labor required from the physics team, minimizes workstation downtime, and creates a clear, auditable record of compliance for accreditation bodies. For any large-scale standardization project, these lifecycle management features14 are just as important as the monitor’s optical performance.

Conclusion

A true diagnostic monitor delivers confidence through strict DICOM Part 14 compliance, automated quality assurance, and a design focused on real-world ergonomics and reliable, fleet-scale management. ✅

👉 For expert recommendations and Reshin diagnostic display solutions, contact martin@reshinmonitors.com.

-

Exploring clinical risk reduction can help you make informed decisions about diagnostic monitors, enhancing patient safety and care quality. ↩

-

Understanding the DICOM Part 14 standard is crucial for ensuring accurate medical imaging, making this resource invaluable for healthcare professionals. ↩

-

Understanding GSDF is crucial for ensuring consistent image quality in medical imaging, making this resource invaluable for professionals. ↩

-

Exploring DICOM compliance helps ensure that medical imaging meets industry standards, enhancing patient care and diagnostic accuracy. ↩

-

Understanding display performance is crucial for accurate diagnostics; explore this link to enhance your knowledge. ↩

-

Learn how TG-18 constancy checks ensure display reliability, which is vital for patient safety and accurate diagnoses. ↩

-

Understanding automated self-calibration can enhance your knowledge of monitor performance and reliability in medical imaging. ↩

-

Exploring DICOM calibration will provide insights into its critical role in ensuring accurate medical imaging and diagnostics. ↩

-

Explore this link to understand how AR glass enhances image quality and reduces glare, crucial for accurate diagnostics. ↩

-

Discover how ambient light sensors optimize brightness for consistent viewing, enhancing the diagnostic experience. ↩

-

Understanding DICOM Part 14 compliance is crucial for ensuring accurate medical imaging, which enhances diagnostic reliability. ↩

-

Exploring sRGB and BT.709 will help you grasp their significance in delivering accurate color representation in medical imaging. ↩

-

Explore this link to understand effective strategies for deploying diagnostic monitors, ensuring reliability and efficiency in large-scale environments. ↩

-

This resource will provide insights into the importance of lifecycle management features, enhancing your understanding of monitor performance and maintenance. ↩