An inconsistent radiology monitor in a PACS setup leads to diagnostic uncertainty. When images look different from one room to another—or even from morning to night—clinical confidence suffers. Build around verified DICOM Part 14 (GSDF), add luminance stabilization and uniformity correction, and keep QA logs audit-ready. Calibrate at operational lux, lock profiles fleet-wide, and standardize hardware and room conditions to deliver predictable, defensible reads.

Build PACS around DICOM Part 14 you can prove—then keep it stable. Choose radiology monitors with luminance stabilization, ambient-light compensation, uniformity correction, and audit-ready QA logs. Calibrate at operational lux, lock profiles, and standardize across rooms. The payoff: consistent reads shift-to-shift, fewer disputes, and faster, safer decisions.

Achieving a truly reliable PACS environment goes beyond purchasing a monitor that claims DICOM compliance. It requires treating the PACS monitor1 as a managed clinical asset with verifiable calibration2, active stabilization technologies, and documented environmental controls. When every element—from front sensors and firmware to reading-room light fixtures—is specified and validated, diagnostic interpretation sits on a stable, reproducible foundation.

Why PACS Needs Verified DICOM Part 14 Monitors

Claiming DICOM compliance is easy; proving it continuously is what matters. A radiology monitor that cannot verify its own performance leaves a critical gap in quality assurance and makes consistency impossible to enforce in PACS.

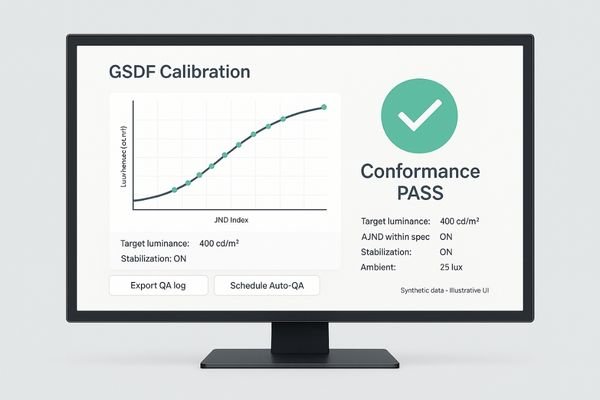

A truly effective PACS display must have verifiable DICOM Part 14 (GSDF) conformance—via integrated sensors, automated calibration, audit-ready QA logs, and fleet-wide profile locking tested under operational lux.

DICOM Part 14 defines the GSDF for consistent perception, but compliance must be an active, verifiable state, not a one-time factory event. A radiology monitor like the MD46C uses a built-in front sensor to run automated GSDF calibration3and generate downloadable QA logs without user intervention. Physics teams can schedule checks and confirm every display meets targets across time and rooms. Crucially, profile locking prevents ad-hoc changes that break calibration. Perform acceptance testing at documented room-lux levels to confirm both the GSDF curve and the monitor’s stabilized luminance before go-live.

Luminance Stabilization and Uniformity for PACS Consistency

A monitor’s brightness can drift through warm-up and long shifts, changing the appearance of low-contrast findings and inviting diagnostic disagreements or rescans.

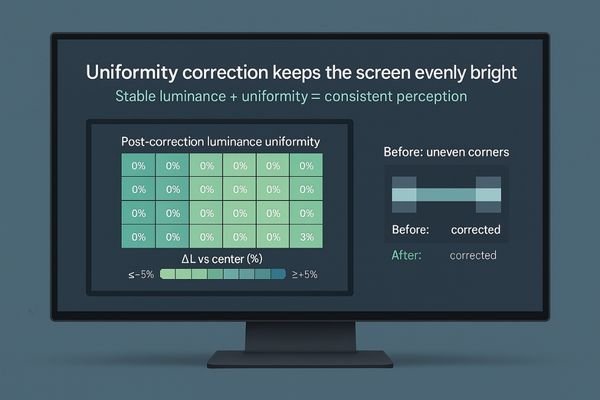

Closed-loop luminance stabilization and factory uniformity correction are essential for shift-to-shift consistency, keeping targets steady and the panel evenly bright across the entire screen.

Radiologist perception is highly sensitive to luminance. Luminance stabilization counters warm-up drift so the target cd/m² holds throughout extended reading sessions. Factory uniformity correction maps the panel and compensates for corner fall-off to preserve near-threshold detail. A dependable PACS monitor4 like the MD26C integrates both systems, delivering the same GSDF response at 08:00 and 20:00 and improving reader agreement across shifts.

Reading Room Control: ALC, Wall Color, Acceptance QA

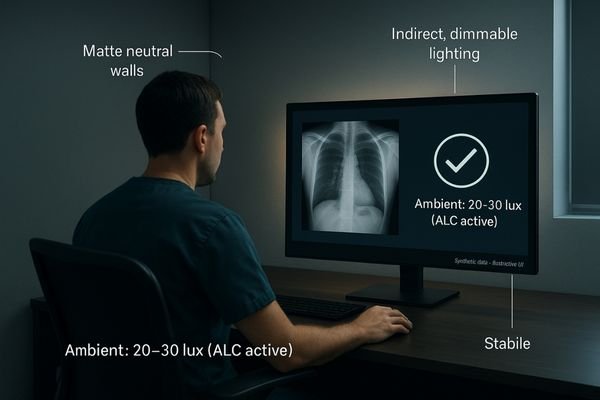

A perfectly calibrated display can be defeated by uncontrolled room lighting: glare lifts shadows, reflections alter perceived grayscale, and reader fatigue rises.

Treat the reading room as part of the PACS chain. Pair monitors with ambient light compensation (ALC) and specify neutral, matte walls and dimmable indirect lighting, then verify performance under real operating lux.

Specify neutral, non-reflective wall colors and clear rules for task lighting5 and shades. Choose a radiology monitor with an ALC sensor that measures room illuminance and adjusts luminance to maintain GSDF perceptual linearity6. A multi-purpose diagnostic display such as MD85CA uses ALC to keep contrast predictable from dark reading rooms to brighter teaching spaces. Acceptance QA should confirm GSDF and luminance at documented lux with paint, lamps, and shades in place; sign off the ALC response as part of commissioning.

| Reading Room Factor | Impact on PACS Display | Best Practice |

|---|---|---|

| Ambient Light | Causes glare and alters perceived contrast. | Use monitors with ALC, specify dimmable, indirect lighting, and document lux targets. |

| Wall Color | Reflective or bright colors can create distracting glare. | Specify neutral, matte-finish paint (e.g., Munsell N5–N7). |

| Ergonomics | Poor placement increases fatigue and angle errors. | Use adjustable stands/arms and define viewing distance/geometry. |

Mixed-Modality PACS: Accurate Color and DICOM Grayscale

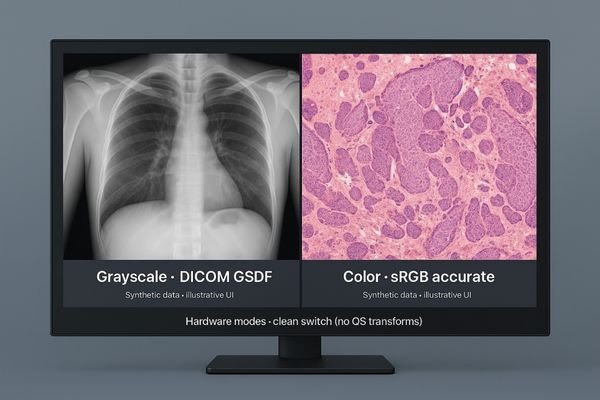

Modern PACS workflows blend grayscale CT/MR with color overlays, reports, ultrasound clips, or pathology slides—often side-by-side.

Select a radiology monitor that hardware-calibrates to DICOM GSDF and provides a validated color mode (e.g., sRGB) with clean driver-level switching and no OS transforms.

If a display cannot render both DICOM grayscale and standard color accurately, readers must mentally compensate, increasing cognitive load and risk. A monitor like the MD22CA supports hardware-calibrated GSDF7 for grayscale and a separate, accurate sRGB mode8 for color content, letting users switch confidently without hidden OS color manipulations. This dual capability streamlines multidisciplinary reviews and complex case comparisons.

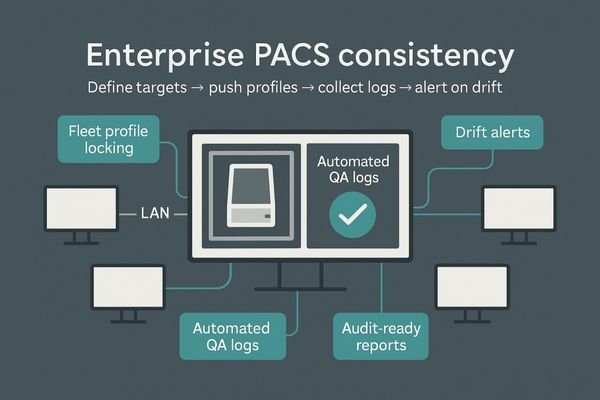

Fleet Profile Locking and QA Logs for Enterprise PACS

In enterprise environments, inconsistency across rooms undermines standardized practice and invites disputes.

Fleet-wide profile locking and centralized QA logging turn policy into reproducible, auditable performance across the PACS estate.

Consistency cannot rely on manual checks. A PACS admin[^9 should define luminance, white point, and GSDF targets and push a locked profile to every PACS monitor. Pair displays like the MD45C with QA software9 to collect automated logs and surface drift alerts. Recommended SOP:

- Define luminance/white-point/GSDF targets.

- Push a locked profile to every workstation.

- Collect QA logs centrally and enable alerts.

- Re-verify after OS/GPU updates or room changes.

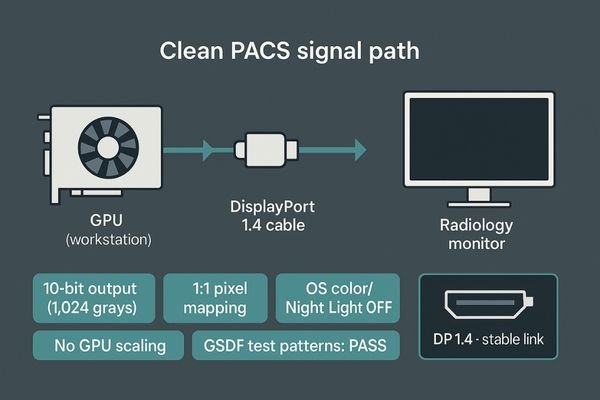

MD46CClean GPU-to-Monitor Pipeline: DP 1.4 and 10-bit

Even the best monitor fails if the signal path is compromised. Misconfigured GPUs, OS color features, and scaling can silently degrade image quality.

Document and validate a clean pipeline: DisplayPort 1.4, 10-bit output, 1:1 pixel mapping, and no OS-level manipulations.

- Use DisplayPort 1.4 and confirm 10-bit output for 1,024 gray levels (vs. 256 at 8-bit).

- Enforce 1:1 pixel mapping; disable GPU/OS scaling.

- Turn off OS “night light,” dynamic contrast, and consumer ICC profiles.

- Validate with GSDF test patterns before sign-off.

A workstation monitor such as the MD32C with DP 1.4 provides the right hardware endpoint; the IT team must lock GPU drivers and OS settings to preserve the calibrated GSDF signal.

Conclusion

A reliable PACS monitor strategy pairs a verified DICOM Part 14 radiology monitor with luminance stabilization, uniformity correction, ALC-controlled rooms, and fleet-level QA logs, ensuring consistent, defensible reads across shifts, rooms, and sites. 🩻

👉 For expert guidance and Reshin PACS monitor solutions, contact martin@reshinmonitors.com.

-

Understanding PACS monitors is crucial for ensuring reliable medical imaging and compliance with standards. ↩

-

Exploring verifiable calibration can enhance your knowledge of maintaining accuracy in medical imaging. ↩

-

Exploring automated GSDF calibration can reveal how it enhances efficiency and accuracy in medical imaging, crucial for healthcare professionals. ↩

-

Exploring the advantages of PACS monitors can enhance your knowledge of efficient image management in radiology. ↩

-

Explore this link to understand how to optimize task lighting for better diagnostic accuracy and comfort. ↩

-

Learn about GSDF perceptual linearity to ensure accurate image interpretation and maintain quality in radiology. ↩

-

Understanding hardware-calibrated GSDF can enhance your knowledge of display technology and its importance in accurate imaging. ↩

-

Exploring accurate sRGB mode will help you grasp its significance in achieving true color representation in various applications. ↩

-

Exploring top QA software options can enhance your workflow and ensure compliance in medical imaging. ↩