Outdated displays can compromise diagnostic accuracy and surgical precision. This creates unacceptable risks for patient care and professional liability. Advanced panel manufacturing provides the solution by engineering displays for specific clinical demands.

Panel technology advancements are improving resolution, brightness, user comfort, and durability. These innovations, combined with smart features and efficient production, are redefining the performance and reliability of modern medical displays.

These developments represent a fundamental shift in medical imaging capabilities1. The panel is the core of any display, and its underlying technology dictates everything from image fidelity to long-term reliability. The following sections explore how these manufacturing advances translate into tangible clinical benefits, demonstrating why choosing a display with the right panel technology2 is so critical.

Improved panel technologies deliver higher resolution and image clarity for medical applications

Low-resolution images can obscure fine anatomical details. This ambiguity can lead to diagnostic uncertainty or procedural errors. Modern panel technologies now provide the pixel density needed for confident clinical interpretation.

The industry has shifted from adapting consumer-grade technology to developing truly medical-grade manufacturing processes. This focus on clinical requirements ensures compliance with standards like DICOM and enables the high resolutions needed for precise diagnostics.

The transition to higher resolutions like 4K and 8K3 is one of the most significant advances in panel manufacturing. This is achieved by reducing the size of individual pixels and the space between them. This smaller pixel pitch allows more pixels to be packed into the same screen area, creating a smoother, more detailed image. This detail is critically important in medical imaging. In radiology, it allows for the clear visualization of microcalcifications in a mammogram or subtle nodules in a chest CT scan. Panel technologies like In-Plane Switching (IPS)4 have also become standard. They ensure not only high resolution but also excellent color accuracy and wide viewing angles. This means a consistent, reliable image is visible from various positions in a reading room or operating theater. Displays like the MD120C embody this progress, delivering the image clarity required for the most demanding diagnostic tasks.

| Resolution | Pixel Count (Width x Height) | Total Pixels | Primary Clinical Use |

|---|---|---|---|

| Full HD (2MP) | 1920 x 1080 | ~2.1 Million | Clinical Review, Modality Control |

| QHD (3MP/4MP) | 2560 x 1440 | ~3.7 Million | General Radiology, CT/MRI |

| 4K UHD (8MP) | 3840 x 2160 | ~8.3 Million | Multi-modality, Surgical, Mammography |

| 8K UHD (33MP) | 7680 x 4320 | ~33.2 Million | Advanced Surgical, Future Applications |

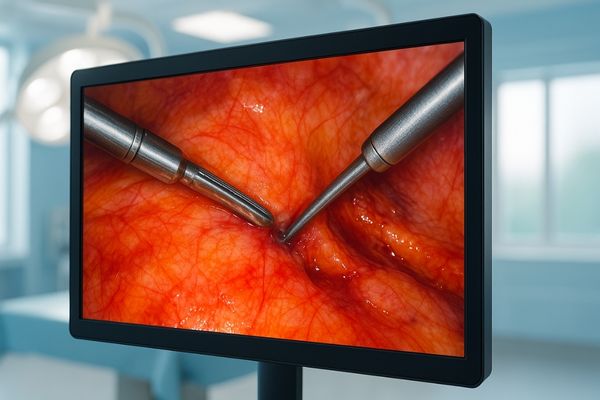

Enhanced brightness and contrast performance meet demanding surgical visualization requirements

Variable ambient light in an operating room can easily wash out a standard display image. This can dangerously obscure the surgeon’s view of the surgical field. High-brightness, high-contrast panels are built to overcome these conditions.

High-brightness and high-contrast panels are increasingly critical in surgical environments. Precision is paramount, and these enhanced panels cut through variable ambient lighting to ensure a consistently clear and detailed view of the anatomy.

Panel manufacturers have made significant strides in boosting both luminance and contrast ratios5. Brightness, measured in candelas per square meter (cd/m²), must be high enough to compete with the powerful overhead lights in an OR. Modern medical panels achieve brightness levels far exceeding those of consumer displays, ensuring the image remains vivid. At the same time, a high contrast ratio is essential for differentiating between subtle shades of tissue. This is especially important in the low-light conditions of endoscopic surgery. Advanced panel technologies achieve this with deeper black levels and more brilliant whites. This perception of depth allows surgeons to distinguish between delicate structures with greater confidence. The backlighting system is key to this performance. Direct LED backlighting6 gives more uniform brightness and better contrast control than older designs. A specialized display like the MS321PB integrates these panel advancements to deliver uncompromising visual performance.

Innovations in low blue light and anti-glare coatings reduce eye strain for medical professionals

Staring at bright screens for hours causes significant eye fatigue. This chronic strain can reduce diagnostic accuracy and impact the long-term well-being of medical professionals. New panel innovations prioritize user comfort.

Low blue light and flicker-free technologies improve more than just comfort. They actively reduce the eye strain and mental fatigue associated with long diagnostic reading sessions, helping to sustain professional endurance and accuracy.

Panel manufacturing now incorporates features specifically designed to mitigate the causes of digital eye strain. One major innovation is hardware-level low blue light technology7. These advanced panels modify the LED light source itself to reduce high-energy blue light while maintaining color accuracy. This is superior to simple software filters that cast a yellow tint over the image. This feature helps protect the user’s eyes and reduce disruptions to their circadian rhythm. Another key advance is flicker-free backlighting8. This system uses direct current (DC) to modulate brightness instead of the pulse-width modulation (PWM) that causes imperceptible but fatiguing screen flicker. Finally, advanced surface coatings are applied to the panel. Anti-glare (AG) coatings use a micro-textured surface to diffuse ambient light. Anti-reflection (AR) coatings use optical physics to cancel out reflected light waves. A monitor like the MD51CHY combines these technologies for a more comfortable viewing experience.

Advances in durability and cleanability support strict infection control protocols in hospitals

Harsh chemical disinfectants can quickly degrade an ordinary monitor’s housing and screen. This deterioration compromises hygiene and shortens the life of the equipment. Medical-grade panels are built to withstand these conditions.

Manufacturing advances in materials have led to stronger protective coatings and sealed panel designs. These features greatly improve a display’s durability against the frequent cleaning required to support strict hospital infection control.

The physical construction of a medical display panel is a critical design consideration. To meet infection control standards, panels are housed behind a seamless, edge-to-edge protective layer. This layer is often made of chemically strengthened glass or a durable acrylic. This design eliminates seams and gaps where contaminants could accumulate. The protective surface itself is manufactured to be non-porous and resistant to the harsh disinfectants used in hospitals, such as quaternary ammonium compounds. This ensures the optical clarity of the panel is not compromised over time by chemical damage. Furthermore, many medical displays have a high Ingress Protection (IP) rating9 on their front surface. An IP65 rating, for instance, certifies that the device is sealed against dust and jets of water. This allows for safe and thorough cleaning without risk of damage. The MS430PC is designed with these principles of durability and cleanability in mind, making it suitable for sterile environments.

Energy-efficient manufacturing processes reduce environmental impact and operational costs

Hospitals are under increasing pressure to reduce operational costs and their carbon footprint. Traditional displays can consume significant power and generate excess heat. Modern, energy-efficient panel manufacturing directly addresses these concerns.

Energy-efficient production methods, especially optimizations in LED backlighting, align with the healthcare industry’s growing commitment to sustainability. These advances reduce electricity consumption, lowering operational costs and supporting green hospital initiatives.

The universal shift from Cold Cathode Fluorescent Lamp (CCFL) backlights to Light Emitting Diodes (LEDs)10 has been an impactful change. LED backlights are significantly more energy-efficient, consuming less power to produce the same brightness. This evolution in manufacturing has substantially lowered the typical power draw of medical displays, leading to direct cost savings. This efficiency also means that the panels generate less heat. This can reduce the load on a hospital’s heating, ventilation, and air conditioning (HVAC) systems. Modern panels also incorporate smart power-saving features. For example, some displays have a presence sensor that automatically puts the monitor into a low-power sleep mode when the user steps away. These energy-saving designs11, found in monitors like the MD26GA, contribute to a lower total cost of ownership and help hospitals achieve their environmental goals.

| Feature | CCFL Backlight (Older Tech) | LED Backlight (Modern Tech) |

|---|---|---|

| Power Consumption | High | Low (approx. 30-50% less) |

| Heat Generation | Significant | Minimal |

| Lifespan | Shorter | Longer |

| Brightness Control | Limited | Precise and Dynamic |

Integration of smart calibration and uniformity correction streamlines display maintenance

Manual display calibration is a time-consuming and often inconsistent process. If not performed accurately, display performance can drift and compromise diagnostic confidence. Integrated smart sensors automate this critical task.

Built-in smart sensors that provide automated calibration and uniformity correction are a key manufacturing advance. This technology ensures consistent DICOM compliance over the display’s lifetime, simplifying maintenance and guaranteeing reliable image quality.

Medical displays used for radiology must comply with the DICOM Part 1412 standard for grayscale presentation. This once required periodic manual calibration by an engineer using an external photometer. Advanced panel manufacturing has revolutionized this process by integrating the calibration system into the display. These monitors feature a small sensor built into the front bezel. At scheduled intervals, this sensor measures the panel’s light output. It then automatically adjusts the display’s internal lookup table (LUT) to perfectly match the DICOM curve. Another integrated feature is uniformity correction13. This process measures the brightness at various points across the panel and adjusts them to ensure the screen is perfectly even. This is vital for comparing images accurately. Displays like the MD50C include these smart features, guaranteeing consistent performance and freeing up valuable technical staff time.

Brands like Reshin leverage cutting-edge panel manufacturing to deliver specialized surgical and diagnostic solutions

Generic, off-the-shelf panels cannot meet the diverse requirements of different medical applications. This forces healthcare providers to compromise on performance. Specialized brands overcome this by creating purpose-built displays.

Our adoption of advanced panel manufacturing processes positions us to meet future demands for higher resolution, better color accuracy, and increased reliability in specialized medical applications.

Our strategy is to harness these cutting-edge panel manufacturing processes to build solutions for specific clinical needs. We do not use a one-size-fits-all approach. For our surgical displays14, we select panels with the highest brightness, contrast, and fastest response times. We then integrate them into housings designed for durability and infection control. For our diagnostic displays15, we prioritize panels with exceptional pixel density, color accuracy, and built-in calibration for consistent DICOM compliance. We work closely with panel manufacturers and develop our own proprietary driving electronics and image processing algorithms. This allows us to optimize performance for each use case. This focus on specialized solutions, such as our MS275P, helps us meet and exceed the demands of modern medicine. This deep integration of technology is how we provide reliable, high-performance displays that empower medical professionals.

Conclusion

Advances in panel manufacturing are the primary engine of progress in medical visualization. These innovations enhance diagnostic confidence, surgical precision, and professional well-being, shaping the future of healthcare.

📧 Interested in next-generation panel technology for medical displays? Contact Martin at martin@reshinmonitors.com to explore Reshin’s cutting-edge solutions.

- Explore this link to understand how innovations in medical imaging are transforming healthcare and improving patient outcomes. ↩

- Discover the significance of panel technology in enhancing image quality and reliability in medical displays. ↩

- Explore how 4K and 8K resolutions enhance medical imaging, providing clearer and more detailed visuals for accurate diagnoses. ↩

- Learn about IPS technology and its advantages in delivering high resolution and color accuracy for medical displays. ↩

- Understanding contrast ratios can enhance your knowledge of medical display technology and its impact on surgical outcomes. ↩

- Exploring this topic will reveal how backlighting technology enhances image quality in medical environments. ↩

- Explore this link to understand how low blue light technology can protect your eyes and enhance your viewing experience. ↩

- Discover the advantages of flicker-free backlighting and how it can reduce eye strain during prolonged use. ↩

- Exploring IP ratings helps you grasp their significance in protecting medical devices from environmental hazards. ↩

- Explore this link to understand how LEDs enhance medical display technology, improving efficiency and reducing costs. ↩

- Discover the impact of energy-saving designs on hospital operations and cost management by visiting this resource. ↩

- Understanding DICOM Part 14 is crucial for ensuring compliance in medical imaging, enhancing your knowledge of radiology standards. ↩

- Exploring uniformity correction will help you grasp its importance in achieving accurate image comparisons in radiology. ↩

- Explore this link to discover cutting-edge innovations in surgical displays that enhance medical procedures and outcomes. ↩

- Learn about the importance of DICOM compliance in diagnostic displays and how it impacts medical imaging accuracy. ↩