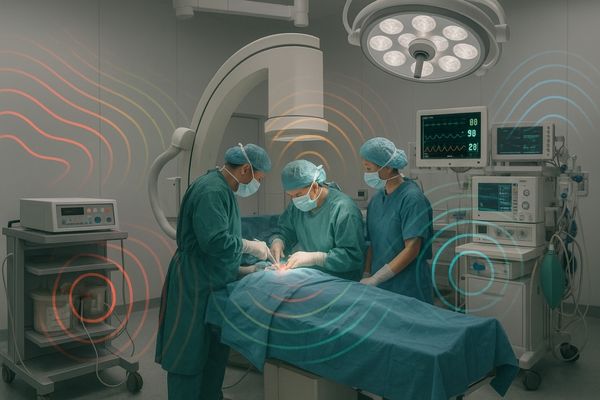

Unseen electronic noise can cause critical equipment to fail in the operating room. This interference risks patient safety, but the right monitor materials provide a crucial defense against this invisible threat.

Yes, medical monitor materials are rigorously tested for electromagnetic shielding. This is mandated by safety standards like IEC 60601-1-2. Materials such as metal housings provide superior protection, ensuring devices do not emit or receive harmful interference in sensitive clinical environments.

In my experience, electromagnetic compatibility1 is one of the most important, yet least visible, aspects of medical device safety2. I have seen how stray electronic signals can disrupt vital equipment. This is why shielding is not just a technical feature. It is a fundamental safety requirement. The materials and design of a monitor’s housing play a direct role in its ability to function safely alongside other devices. In this article, I will explain why this shielding3 is so critical, the standards that govern it, and how we ensure our displays are safe for any surgical environment.

Why is electromagnetic shielding critical in surgical environments?

A patient’s vital signs suddenly appear erratic on screen. This false data could lead to a dangerous clinical decision, but proper shielding ensures that all readings remain true and reliable.

Electromagnetic shielding is critical because it prevents electromagnetic interference (EMI) from disrupting essential surgical equipment. This ensures the stable operation of devices like patient monitors, anesthetic machines, and imaging systems, which is paramount for maintaining patient safety during procedures.

A modern operating room is a dense electronic environment. It is filled with devices that generate electromagnetic energy. These sources include electrosurgical units (ESUs)4, which use high-frequency currents to cut tissue, as well as C-arms, communication systems, and anesthetic machines. At the same time, many devices are also susceptible to this energy. For example, EMI could cause a patient monitor to display incorrect heart rate data, an infusion pump to deliver the wrong dose, or a surgical display to flicker or freeze. Patient safety depends on every single one of these devices working perfectly and without interruption. Electromagnetic shielding ensures that each device is a "good electronic citizen." It prevents a device from emitting enough EMI to disturb its neighbors. It also ensures the device is immune to the ambient EMI from other equipment. A monitor like the compact MS192SA, often used in tight spaces on equipment booms, must have excellent shielding to perform reliably while being in close proximity to numerous other electronic instruments.

What standards govern EMI testing for medical displays?

You see a monitor advertised as "shielded," but there is no proof. Without verification from a trusted authority, you are taking a significant risk with equipment reliability and patient safety.

The primary standard governing EMI testing is IEC 60601-1-2. This global standard sets strict limits for both the electromagnetic emissions from a device and its immunity to external interference. Compliance is mandatory for legal market approval in most regions.

Manufacturers cannot simply claim their devices are safe from EMI. They must prove it through standardized testing. The international benchmark for this is the IEC 60601-1-2 standard5. This regulation is a collateral standard within the broader IEC 60601 family, which covers the basic safety and essential performance of all medical electrical equipment. The EMI standard has two main pillars. The first is emissions6. This test measures the amount of electromagnetic noise the monitor generates during operation. The device must not exceed strict limits, ensuring it does not interfere with other equipment. The second pillar is immunity7 (or susceptibility). This test exposes the monitor to controlled levels of various types of electromagnetic energy to ensure it can continue to operate safely without performance degradation. Passing these tests is not optional. It is a legal requirement to obtain the CE mark for sale in Europe and is closely aligned with FDA requirements in the United States. Our MS247SA monitor, like all our medical products, undergoes this rigorous third-party testing to guarantee it meets these essential safety requirements.

Key Requirements of IEC 60601-1-2

| Test Category | Purpose | Example Test Method |

|---|---|---|

| Emissions | To ensure the device does not interfere with other equipment. | Measuring radiated and conducted electronic noise. |

| Immunity | To ensure the device can withstand external interference. | Exposing the device to electrostatic discharge (ESD) and radio waves. |

| Risk Management | To identify and mitigate risks related to EMI. | Analyzing potential hazards from EMI in the intended use environment. |

How do materials like metal housings contribute to shielding effectiveness?

A monitor with a weak enclosure can act like an open window for electronic noise. This exposes sensitive internal components to interference, but a metal housing acts as a protective fortress.

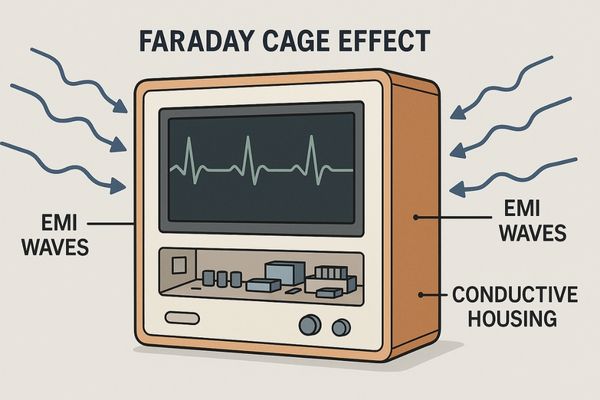

Metal housings, made from materials like aluminum or steel, create a Faraday cage. This conductive enclosure absorbs and reflects ambient electromagnetic waves, effectively blocking them from reaching sensitive internal electronics or escaping from the device.

A metal housing provides EMI shielding8 based on a principle discovered by Michael Faraday in the 1830s. A conductive shell, known as a Faraday cage9, blocks electromagnetic fields. When an external electromagnetic wave hits the metal casing, it induces an electrical current in the conductive material. This current creates its own electromagnetic field that perfectly cancels out the external wave’s effect inside the enclosure. This effectively isolates the sensitive internal electronics from outside interference. The same principle works in reverse, preventing electronic noise generated by the monitor’s own internal components from radiating outward. The choice of metal is important. Aluminum is lightweight and has excellent conductivity, making it a popular choice. Steel provides superior shielding against low-frequency magnetic fields. However, the material alone is not enough. The design must be continuous. Any gaps, seams, or holes for cables and ventilation can act as leaks. Therefore, these openings are protected with conductive gaskets10, EMI mesh screens, and shielded connectors to maintain the integrity of the Faraday cage. Our MS275P surgical monitor uses a robust aluminum alloy housing engineered to provide this seamless shielding.

Are plastic enclosures reliable for EMI protection in medical devices?

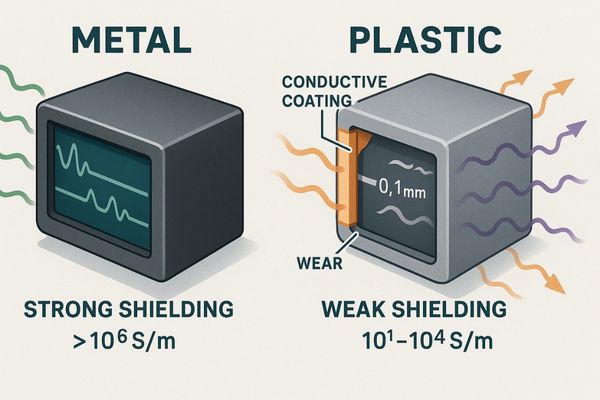

Plastic enclosures are lightweight, but they are naturally transparent to electronic noise. This makes them a potential liability in a medical environment unless they are specially treated to block interference.

Standard plastic enclosures are not reliable for EMI protection because plastic is an electrical insulator. To provide shielding, they must be treated with conductive coatings or filled with conductive materials, which can be less durable and consistent than a solid metal housing.

Plastic is fundamentally an insulator, which means it does not conduct electricity and therefore does not block electromagnetic waves. A standard, untreated plastic housing offers virtually no EMI shielding11. To make a plastic enclosure suitable for a medical device, it must undergo secondary processing to make it conductive. There are two common methods for this. The first is applying a conductive coating12, where the interior of the plastic shell is sprayed with a thin layer of metal like copper or nickel. This creates a functional Faraday cage. The second method involves using conductive plastics13, where conductive fibers like carbon or stainless steel are mixed into the plastic resin before it is molded. Both methods can allow a device to pass EMI certification tests. However, they have drawbacks compared to a solid metal housing. Conductive coatings can be scratched or can flake off over time, especially during maintenance, which compromises the shield. The conductivity of treated plastics may not be as uniform as solid metal. While these solutions are often lighter, the long-term reliability and durability of a solid metal housing are generally superior for critical applications. This is why for a robust monitor like the MS321PB, material selection is a critical part of the design process.

EMI Shielding Material Comparison

| Feature | Solid Metal Housing | Treated Plastic Housing |

|---|---|---|

| Inherent Shielding | Excellent | None (requires treatment) |

| Durability | High | Lower (coatings can scratch) |

| Consistency | Uniform and predictable | Can be non-uniform |

| Weight | Heavier | Lighter |

| Cost | Generally higher material cost | Lower base cost, but treatment adds expense |

How does Reshin ensure its surgical monitors meet EMI safety requirements?

You need absolute confidence that your monitor is safe and compliant. A simple claim from a manufacturer is not sufficient; a rigorous, verifiable testing process is the only way to guarantee performance.

We ensure EMI compliance through a multi-stage process. This begins with designing monitors with shielding in mind, using robust metal housings. We then conduct extensive in-house pre-compliance tests before submitting every model for official third-party certification against IEC 60601-1-2.

Ensuring our monitors are safe from electromagnetic interference14 is a core part of our design and quality assurance philosophy. Our process is built on three key stages. First, we design for compliance from the very beginning. This means selecting the right materials, such as high-grade aluminum alloy housings, and using shielded components and connectors. The internal layout of the electronics is carefully planned to minimize internal crosstalk and potential emissions. Second, we perform extensive pre-compliance testing15 in our own dedicated lab. We use specialized equipment to simulate the harsh electromagnetic environment of a modern operating room. This allows us to identify and resolve any potential EMI issues long before the product is finalized. This in-house stage saves significant time and ensures a higher probability of passing the final certification. The third and final stage is independent verification. We send the finished product to an accredited, third-party laboratory. They conduct the official, unbiased tests required for IEC 60601-1-2 certification16. This final step provides the definitive proof that our monitors, including large-format displays like the MS430PC, are safe, reliable, and ready for the most demanding surgical environments.

Conclusion

Medical monitors are tested for electromagnetic shielding according to strict international standards. This is a non-negotiable safety feature, achieved through careful design, robust materials like metal, and rigorous, independent certification. For medical displays engineered with advanced electromagnetic protection, contact Reshin at martin@reshinmonitors.com.

- Understanding electromagnetic compatibility is crucial for ensuring the safety and effectiveness of medical devices in various environments. ↩

- Learning about medical device safety can help you understand the critical aspects that ensure patient safety and device reliability. ↩

- Exploring the importance of shielding can provide insights into how it protects vital medical equipment from interference. ↩

- Learn about ESUs to appreciate their importance in surgical procedures and the potential risks of EMI. ↩

- Understanding this standard is crucial for manufacturers to ensure compliance and safety in medical devices. ↩

- Learn about emissions testing to understand how devices can be evaluated for electromagnetic safety. ↩

- Explore immunity testing to see how devices are protected against electromagnetic interference, ensuring safe operation. ↩

- Explore advanced techniques and materials for effective EMI shielding to enhance your electronic device’s performance. ↩

- Understanding the Faraday cage principle is essential for grasping how EMI shielding protects sensitive electronics. ↩

- Learn about conductive gaskets and their critical role in maintaining the integrity of EMI shielding in electronic devices. ↩

- Understanding EMI shielding is crucial for ensuring device reliability in medical applications. Explore this link for in-depth insights. ↩

- Learn about conductive coatings and their role in enhancing plastic enclosures for medical devices. This resource provides valuable information. ↩

- Discover the process and benefits of conductive plastics in device manufacturing, essential for modern technology applications. ↩

- Understanding electromagnetic interference is crucial for ensuring device safety and performance. Explore this link to learn more about its impact. ↩

- Pre-compliance testing can save time and costs in product development. Learn how it enhances product reliability and compliance. ↩

- IEC 60601-1-2 certification is vital for medical device safety. Discover its significance and requirements through this informative resource. ↩