A medical display faces constant use and harsh cleaning protocols. Inferior housing materials can crack, degrade, or harbor pathogens, compromising patient safety and equipment longevity. Choosing the right material is the first line of defense.

A display’s housing material defines its durability, safety, and regulatory compliance. Metal offers resilience and heat dissipation, plastic provides lightweight and cost benefits, and specialized surfaces are vital for infection control.

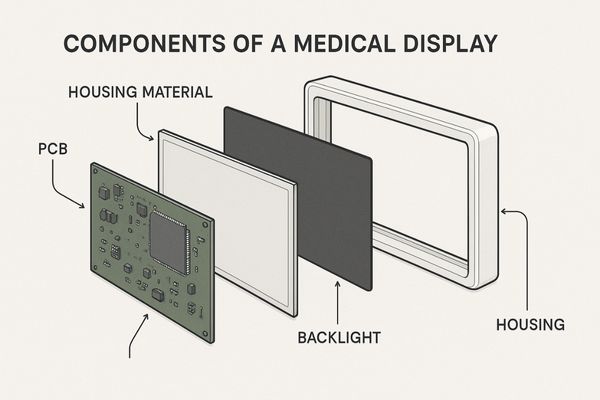

The outer casing of a medical display1 is far more than a simple protective shell. It is an engineered component that directly impacts the device’s performance, safety profile, and lifespan in a demanding clinical setting. Every material choice involves a series of trade-offs between physical durability, thermal management, weight, cost, and the ability to meet stringent hygiene and regulatory requirements. Understanding these material properties2 is essential for any professional involved in procuring or using medical technology. We will now explore the most common housing materials and surface treatments used in modern medical displays.

Metal Housings Provide Durability and Heat Dissipation

High-performance displays generate significant heat during use. Without effective cooling, they can overheat and fail, potentially during a critical procedure. A metal housing provides a robust, built-in solution.

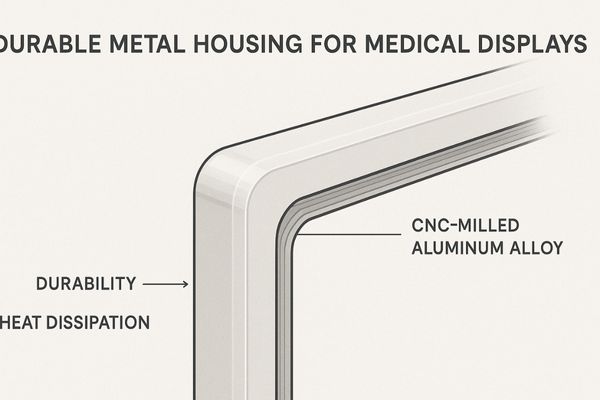

Metal housings, typically made of aluminum alloys, are exceptionally robust and dissipate heat efficiently. This makes them ideal for high-performance medical displays that must operate continuously without failure.

In critical care environments like operating rooms, displays must be reliable above all else. Metal housings, most often crafted from high-grade aluminum alloys, provide superior structural integrity. They are resistant to the physical impacts, bumps, and scrapes that are common in a busy clinical workspace. Beyond simple toughness, metal is an excellent thermal conductor. High-resolution surgical displays generate heat from their backlights and processing electronics. Instead of relying on failure-prone cooling fans that can circulate dust and pathogens, a well-designed metal housing acts as a large, passive heat sink. It draws heat away from sensitive internal components and dissipates it silently into the ambient air. This fanless design is quieter and, more importantly, more hygienic. The precision of CNC (Computer Numerical Control) milling3 allows for seamless, single-body construction, which further minimizes gaps where contaminants could accumulate. For these reasons, devices like the MS321PC – 32" 4K Surgical Monitor utilize metal housings4 to ensure peak performance and reliability.

| Property | Metal Housing (Aluminum Alloy) | Plastic Housing (Medical-Grade Polymer) |

|---|---|---|

| Durability | High (Resistant to impact and scratches) | Moderate (Can scratch or crack) |

| Heat Dissipation | Excellent (Acts as a passive heat sink) | Poor (Acts as an insulator) |

| Weight | Heavier | Lighter |

| Cost | Higher | Lower |

Plastic Housings Offer Lightweight and Cost Advantages

Hospitals need reliable displays everywhere, not just in the operating room. Heavy, expensive models are not always feasible for mobile carts or general-purpose use. Plastic offers a practical and versatile alternative.

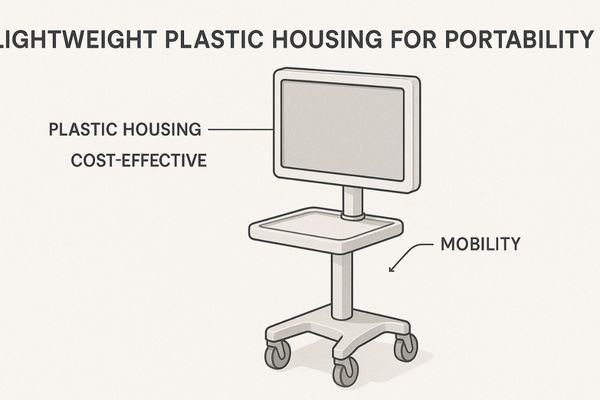

Plastic housings are lightweight and more cost-effective to produce. This makes them highly suitable for portable applications and budget-conscious scenarios, though they are generally less durable than metal options.

When a display needs to be mounted on a mobile equipment cart, an articulating arm, or a non-load-bearing wall, weight becomes a primary consideration. This is where medical-grade polymers5, such as polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) blends, offer a distinct advantage. These plastics are significantly lighter than metal, which reduces strain on mounting systems and makes equipment easier for staff to move and position. The manufacturing process for plastic housings, typically injection molding6, is also more cost-effective, especially for high-volume production. This allows institutions to deploy reliable displays in more locations without straining their budgets. Injection molding also provides greater design flexibility, enabling the creation of complex, ergonomic shapes with integrated handles or cable management features. While they may not offer the same level of impact resistance or passive cooling as aluminum, for many applications, the benefits of weight reduction and affordability are paramount. A model like the MS220S – 22" FHD Endoscopic Monitor is an excellent example of this balance, providing clinical-grade performance in a lightweight and economical package.

Antimicrobial Coatings Enhance Infection Control

Every surface in a hospital is a potential reservoir for infection. Standard materials can allow microbes to survive for hours or even days. An antimicrobial coating actively fights this persistent risk.

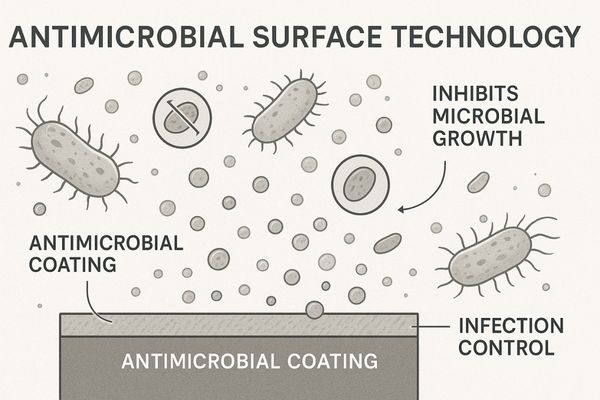

Specially formulated antimicrobial coatings actively inhibit or destroy microbial life on the housing’s surface. This provides an essential layer of protection in sensitive areas like operating rooms and intensive care units.

Infection control is a top priority in any healthcare facility. While regular cleaning is essential, antimicrobial technologies7 provide an additional, continuous line of defense. These are not just special paints; they are advanced coatings where an antimicrobial agent, commonly a silver-ion compound, is integrated directly into the material. The technology works on a microscopic level. When moisture from the air or touch is present, the coating releases silver ions (Ag+). These ions penetrate the cell walls of bacteria, disrupting their metabolism and preventing them from reproducing. This process is bacteriostatic8 (inhibits growth) and can also be bactericidal (kills existing microbes). This active protection helps to reduce the microbial load on high-touch surfaces between cleanings, lowering the risk of cross-contamination. For equipment used in sterile or highly sensitive environments, such as the MS270P – 27" FHD Surgical Display, an antimicrobial housing is not a luxury but a fundamental component of patient safety protocols.

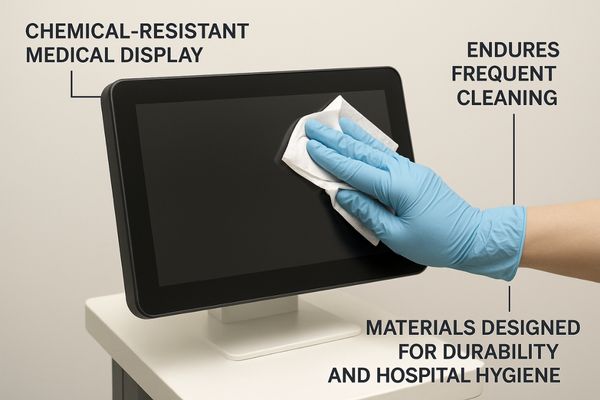

Chemical-Resistant Surfaces Support Frequent Cleaning

Harsh disinfectants are essential for hospital hygiene protocols. These chemicals, however, can degrade standard plastics and coatings over time, causing damage. Chemical-resistant materials are built to withstand this daily routine.

Displays with chemical-resistant surfaces can withstand frequent cleaning with powerful hospital-grade disinfectants. This durability ensures the housing maintains its integrity and meets stringent medical hygiene standards.

Hygiene protocols in hospitals require that equipment be cleaned and disinfected frequently, often multiple times a day. The cleaning agents used are powerful and chemically aggressive, including various alcohol solutions, quaternary ammonium compounds, and diluted bleach (sodium hypochlorite). Standard consumer-grade plastics and coatings are not designed for this kind of exposure. Over time, these chemicals can cause the material to become brittle, develop micro-cracks, yellow, or lose its smooth finish. This not only affects the device’s appearance but can also compromise its structural integrity and create textured surfaces where pathogens can hide. To prevent this, medical displays must use specific polymers and surface coatings that are engineered for chemical resistance9. These materials undergo rigorous testing to ensure they can withstand thousands of wipe-down cycles with common hospital disinfectants10 without degrading. This resilience is vital for maintaining a sterile environment and is a key feature of products like the MD32C – 3MP Diagnostic Monitor.

| Disinfectant Type | Common Active Ingredient | Potential Impact on Non-Resistant Materials |

|---|---|---|

| Alcohol-based | Isopropyl Alcohol, Ethanol | Can cause clouding, crazing, and brittleness. |

| Quaternary Ammonium | Benzalkonium Chloride | Can lead to discoloration and surface tackiness. |

| Bleach Solution | Sodium Hypochlorite | Highly corrosive; can embrittle and degrade plastics. |

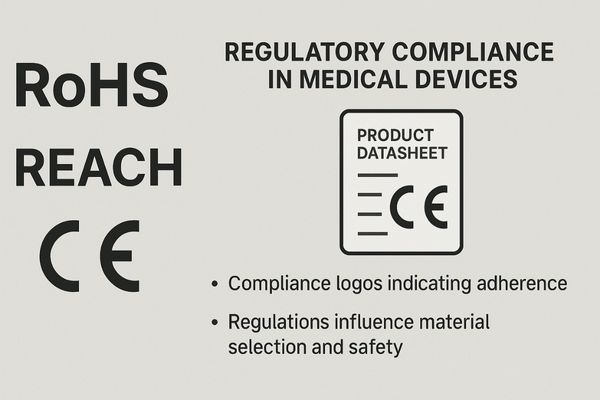

Material Selection Impacts Certification and Regulatory Compliance

Choosing a display is not only about its technical features. If its materials are not certified as safe, the product cannot legally be sold or used in a medical environment. Regulatory compliance is a non-negotiable requirement.

Housing materials must comply with environmental and safety standards like RoHS and REACH. This compliance is essential for obtaining necessary certifications and ensuring a smooth procurement process globally.

Before a medical display can enter the market, its components must pass a battery of safety and environmental tests. The choice of housing material is central to this process. Two of the most critical global regulations are RoHS11 and REACH. The RoHS (Restriction of Hazardous Substances) directive restricts the use of specific hazardous materials, such as lead, mercury, and cadmium, in electronic products. The REACH12 (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation governs a much broader range of chemical substances. Both are designed to protect human health and the environment from chemical risks. Compliance with these standards is a prerequisite for obtaining a CE mark for sale in Europe and is recognized by regulatory bodies worldwide. A manufacturer’s failure to use compliant materials would result in immediate failure of the certification process. Therefore, procuring teams must ensure that any considered product, especially a high-end device like the MD120C – 12MP High-Precision Diagnostic Monitor with AI Calibration, has its material compliance well-documented.

Conclusion

The housing material is not just a shell. It is a critical component that defines a medical display’s durability, safety, thermal performance, and ability to be certified for clinical use.

📩 Looking for medical displays engineered with durable and safe housing materials? Contact Martin at martin@reshinmonitors.com to learn more about Reshin’s solutions.

-

Exploring this link will provide insights into the essential features and specifications of medical displays, crucial for informed decision-making. ↩

-

This resource will help you understand the significance of material properties in enhancing the performance and safety of medical devices. ↩

-

Discover the advantages of CNC milling in creating high-quality medical devices with minimal contamination risks. ↩

-

Explore this link to understand how metal housings enhance durability and hygiene in critical care environments. ↩

-

Explore how medical-grade polymers enhance display mounting solutions, offering lightweight and cost-effective options for various applications. ↩

-

Learn about the advantages of injection molding in creating efficient, cost-effective, and flexible designs for plastic housings. ↩

-

Explore this link to understand how antimicrobial technologies enhance infection control and patient safety in healthcare settings. ↩

-

Learn about the significance of bacteriostatic properties in preventing bacterial growth and improving hygiene in medical environments. ↩

-

Understanding chemical resistance is crucial for ensuring the longevity and safety of medical equipment in hospitals. ↩

-

Exploring effective disinfectants can help maintain hygiene standards and prevent the spread of infections in healthcare settings. ↩

-

Understanding RoHS is crucial for manufacturers to ensure compliance and avoid penalties in the electronics market. ↩

-

Exploring REACH helps manufacturers navigate chemical regulations, ensuring safety and compliance in their products. ↩