Your high-resolution display runs hot, causing performance dips. This heat silently degrades components, but the monitor’s material choice is the key to lasting reliability and stable performance.

Yes, materials are a primary factor in a monitor’s heat dissipation. Metals like aluminum alloys conduct heat away from internal components far more effectively than plastics, directly influencing thermal stability, performance consistency, and the overall lifespan of the display.

I have spent my career focused on the engineering that goes into a high-performance display1. While people often focus on pixels and brightness, the physical construction is just as important. A monitor is an integrated system where electronics and materials must work together. The choice of materials for the housing and internal components is not an aesthetic decision; it is a fundamental engineering choice that dictates how well the monitor can survive the stress of continuous operation. Heat is the primary enemy of all electronics, and in a high-stakes environment like a clinic or operating room, managing it is not optional. In this article, I will explain why modern displays generate so much heat, how different materials handle it, and why this is critical for the safety and longevity of your equipment.

Why do high-resolution monitors generate more heat?

Upgrading to a high-resolution display often means more heat. This is not your imagination; it is a direct consequence of the advanced technology packed inside the screen.

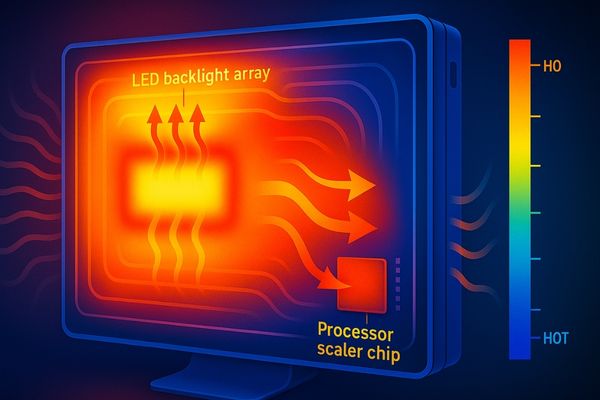

High-resolution monitors generate more heat due to their higher pixel density, brighter backlights, and more powerful internal processors. Rendering millions of pixels requires more electrical energy, and a significant portion of this energy is inevitably converted into thermal energy.

A monitor’s primary function is to convert electrical signals into light, and this process is not 100% efficient. Some energy is always lost as heat. With high-resolution displays2, the factors that generate heat are amplified significantly. First, a screen with more pixels, like a 4K or 8K display3, needs a more powerful backlight unit to push light through the denser LCD matrix and maintain high brightness levels. These powerful LED arrays consume more electricity and produce more heat. Second, processing the vast amount of data required for a high-resolution image demands a more powerful internal processor or scaler. This chip works like the CPU in a computer, and it gets hot under heavy load. In a medical setting, where a monitor might display a complex, multi-layered image for hours, this processing load is constant. The combination of a brighter backlight and a harder-working processor creates a substantial thermal challenge. Our 8MP Diagnostic Display4 is designed to render extremely detailed multi-modality images, and managing the heat from its powerful electronics is a core part of its engineering to ensure image stability over long reading sessions.

How do materials influence thermal conductivity in displays?

Two monitors can look similar, but one is plastic and the other metal. This is not just for style; this choice fundamentally determines how well the monitor can cool itself.

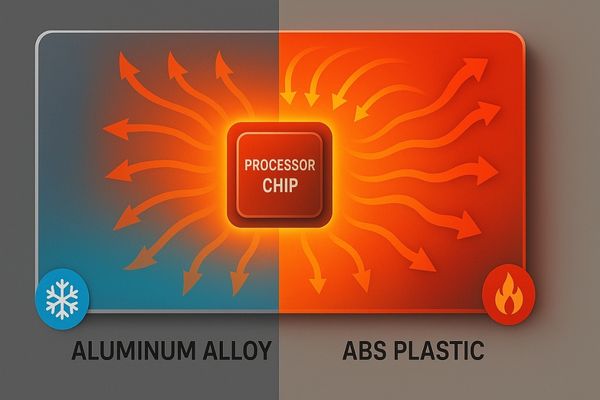

Materials influence thermal conductivity by their innate physical properties. Metals like aluminum are highly conductive, actively pulling heat from processors and LEDs to the chassis surface for dissipation. Plastics, being thermal insulators, trap heat internally, preventing efficient cooling and raising component temperatures.

Thermal conductivity is a measure of a material’s ability to transfer heat. You can feel this difference in everyday life. A metal spoon left in a hot cup of tea will quickly become hot to the touch, while a plastic spoon will remain cool. The metal conducts heat away from the liquid, and the plastic insulates against it. The same principle applies directly to monitor design. When a display’s chassis is made from a material with high thermal conductivity5, like an aluminum alloy, it acts as a large, passive heat sink. It pulls thermal energy away from hotspots, such as the main processor and LED driver board, and spreads it across the entire surface of the monitor. This distribution allows the heat to dissipate safely into the surrounding air. A plastic enclosure does the opposite. As a thermal insulator6, it traps heat inside, concentrating it around the very components that are most vulnerable to heat damage. This is why material selection is a critical engineering decision. For our MS430PC – 43" 4K Surgical Monitor, we use a metal chassis7 to ensure heat from the 4K processor is managed effectively, preventing any performance loss during long surgical procedures.

| Material | Thermal Conductivity (W/mK) | Typical Use in Monitors |

|---|---|---|

| Copper | ~400 | Heat Pipes, Heatsink Cores |

| Aluminum Alloy | ~180-220 | Chassis / Housing, Heatsinks |

| Steel | ~50 | Structural Brackets |

| Plastic (ABS) | ~0.2 | Enclosures (Consumer-grade) |

What are the common heat-dissipating materials in medical-grade displays?

What makes a medical display’s cooling superior to a standard office monitor? It is not magic, but a deliberate engineering choice of advanced, heat-dissipating materials inside.

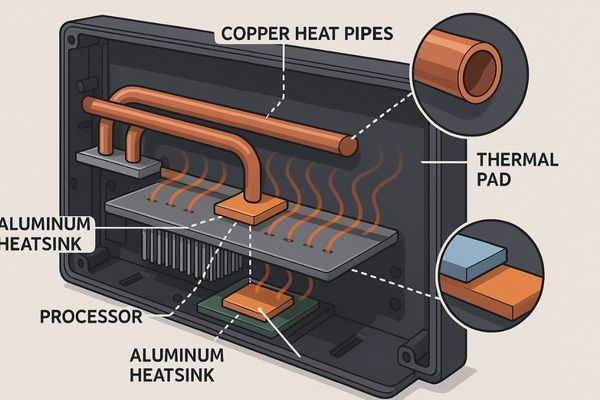

Common heat-dissipating materials in medical displays include anodized aluminum alloy for the housing, which acts as a large heatsink. Internally, copper heat pipes transfer heat from hotspots, and graphite thermal pads are used to spread heat evenly away from critical electronic components.

In my work, designing for a medical environment means prioritizing reliability above all else. This requires a system of high-performance thermal materials. The first line of defense is typically an anodized aluminum alloy chassis8. The aluminum itself is an excellent conductor, and the anodization process can slightly increase its surface emissivity, helping it radiate heat more effectively while also making it durable and easy to clean. Inside the monitor, we use more specialized materials to target specific hotspots. For a high-power processor, a small, finned aluminum or copper heatsink might be attached directly to it. To move heat from a chip in a tight space to the larger chassis, we often use copper heat pipes9. These are remarkable devices that use an internal, phase-changing fluid to transfer heat with extreme efficiency. In some designs, we also use thermal pads made of graphite10. These pads are excellent at spreading heat horizontally, helping to eliminate concentrated hotspots on a circuit board. These materials work together as a passive cooling system, designed to operate silently and without moving parts that could fail or circulate contaminants. Our MD45C – Dual-screen Diagnostic Monitor (Single Panel) uses such a system to manage heat across its large, integrated electronics board, ensuring both screens remain stable.

Can poor material selection lead to thermal failure or reduced lifespan?

Is a hot monitor just an inconvenience? Over time, that heat actively degrades components, leading to dimming, image artifacts, and eventually, a much shorter operational life.

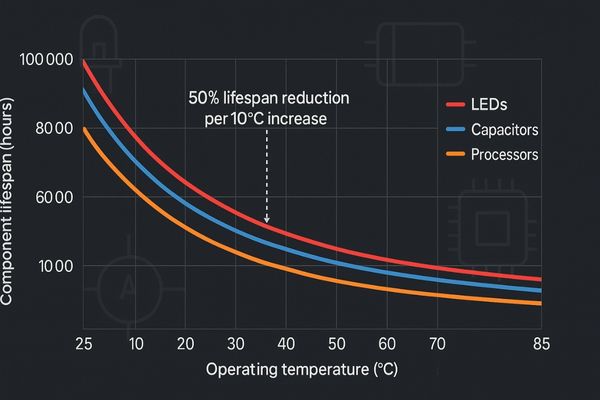

Yes, poor material selection is a direct cause of thermal failure and reduced lifespan. Trapped heat accelerates the aging of LEDs, capacitors, and processors, leading to problems like brightness degradation, color shifts, image artifacts, and eventually, complete component failure.

The relationship between temperature and the lifespan of electronic components is well-documented and unforgiving. As a general rule of thumb in electronics engineering, for every 10°C (18°F) increase in operating temperature1, the expected lifespan of a semiconductor component is cut in half. A monitor built with poor thermal materials, like a simple plastic shell with no internal heat management, will run significantly hotter. This sustained heat becomes a silent killer for the display’s internal parts. The LED backlight will be one of the first victims, with its brightness dimming at an accelerated rate and its color accuracy shifting over time. The capacitors on the power supply and mainboard, which are crucial for stable operation, can dry out and fail, leading to power issues or a completely dead monitor. The image processor itself can start to "throttle," or slow down, to protect itself from overheating, resulting in image lag or stutter. In the worst-case scenario, the heat causes permanent damage. This is why material choice is directly linked to the total cost of ownership2 and patient safety. Our MD50C – 5MP Color Mammography Monitor relies on superior thermal management3 to ensure its luminance and color stability do not drift over its long service life, which is critical for comparative mammogram readings.

| Component | Effect of Sustained High Temperature | Potential Failure |

|---|---|---|

| LED Backlight | Accelerated lumen decay | Dimming, Color Shift |

| LCD Panel | Increased liquid crystal response time | Image Ghosting, Motion Blur |

| Processor/Scaler | Throttling, faster silicon aging | Performance Loss, System Crash |

| Capacitors | Electrolyte evaporation | Power Failure, Screen Flickering |

How does Reshin leverage material engineering to optimize heat dissipation?

How can you be sure a monitor is built to last? Many brands look good but use cheap materials. We focus on advanced material engineering for superior, long-term thermal performance.

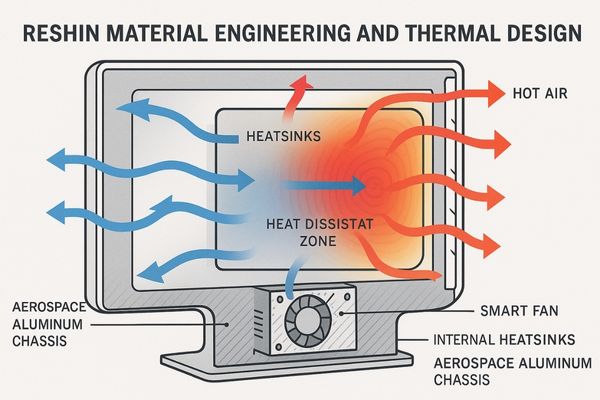

Reshin optimizes heat dissipation by using high-conductivity materials like aerospace-grade aluminum for the chassis and custom internal heatsinks. This passive cooling is often supplemented with smart, thermally-controlled fans and optimized airflow designs to ensure stable, quiet performance under demanding, continuous operation.

My philosophy has always been to build solutions from the ground up, and that starts with the right materials. We do not treat the enclosure as a simple box; we engineer it as a core part of the thermal system. We start with aerospace-grade aluminum alloys11 for the chassis of our high-performance monitors. These materials offer an excellent balance of strength, low weight, and, most importantly, high thermal conductivity. The chassis is designed to act as a giant, passive heatsink12. We then design custom internal heatsinks and heat-spreading components that are tailored to the specific layout of the electronics in each model. This ensures there is a clear, efficient path for heat to travel from the core components to the outside of the monitor. For our most powerful displays, we augment this passive system with active cooling. This is not just a simple fan. We use smart, thermal-sensing fan control13, where the fan speed is precisely modulated based on the real-time temperature of the system. This allows the monitor to run silently during normal operation and only use the fan when absolutely necessary. Our MD120C – 12MP High-Precision Diagnostic Monitor uses this hybrid approach to manage the intense heat from its advanced electronics, ensuring flawless performance for the most demanding radiological applications.

Conclusion

Ultimately, a monitor’s materials are not just cosmetic. They are fundamental to its thermal performance, directly impacting image stability, reliability, and the display’s overall lifespan in a demanding medical environment. To explore medical displays built with performance-optimized materials, contact Reshin at martin@reshinmonitors.com.

- Understanding the features of high-performance displays can help you make informed decisions for your needs. ↩ ↩

- Understanding the heat challenges of high-resolution displays can help in selecting the right monitor for demanding tasks. ↩ ↩

- Exploring the energy and heat implications of 4K and 8K displays can guide informed purchasing decisions for tech enthusiasts. ↩ ↩

- Learning about the 8MP Diagnostic Display can provide insights into advanced imaging technology for medical applications. ↩

- Understanding thermal conductivity is essential for making informed material choices in engineering, especially for heat management. ↩

- Learning about thermal insulators helps in understanding their role in protecting sensitive components from heat damage. ↩

- Exploring the benefits of a metal chassis can reveal how it enhances performance and longevity in electronic devices. ↩

- Explore how anodized aluminum enhances durability and heat management in medical devices, ensuring reliability in critical environments. ↩

- Learn about the efficiency of copper heat pipes in transferring heat, crucial for maintaining performance in compact electronic designs. ↩

- Discover how graphite thermal pads help in heat distribution, preventing hotspots and improving the reliability of electronic circuits. ↩

- Explore the advantages of aerospace-grade aluminum alloys in engineering for high-performance applications. ↩

- Learn about passive heatsinks and their role in efficient thermal management for electronics. ↩

- Discover how thermal-sensing fan control enhances cooling efficiency and performance in electronic devices. ↩