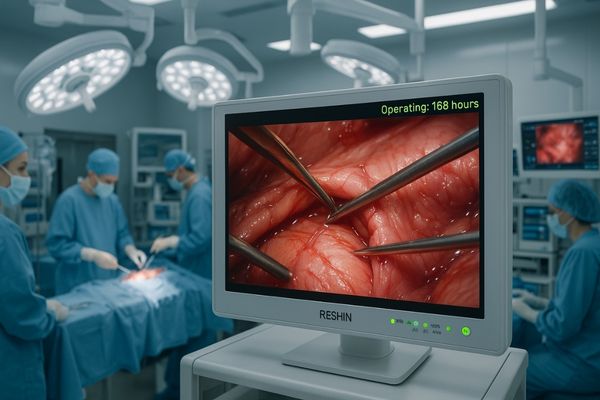

Your operating room runs nonstop, but you worry your surgical monitors will fail under constant use. A flicker or overheat during a procedure is a risk you cannot afford.

Reshin monitors maintain 24/7 performance through industrial-grade components, advanced thermal management, long-life LED backlights, and real-time calibration. These features, validated by IEC 60601 certification, ensure continuous stability, consistent image quality, and reliable operation in demanding medical environments.

The reliability of a surgical display1 is not accidental. It is the result of deliberate engineering choices designed to withstand the pressures of continuous use. From the internal power supply to the external housing, every element plays a role in ensuring that the monitor performs flawlessly, hour after hour. This article will break down the specific technologies and design principles we employ to build monitors capable of true 24/7 operation. We will explore the components that ensure stability, the thermal systems2 that prevent overheating, and the calibration technologies3 that maintain perfect image quality over time, providing the dependability your surgical team requires.

What internal components ensure continuous stability in Reshin monitors?

You have experienced monitor failures caused by cheap internal parts. This unpredictable equipment downtime disrupts surgical schedules and erodes your confidence in the technology you rely on every day.

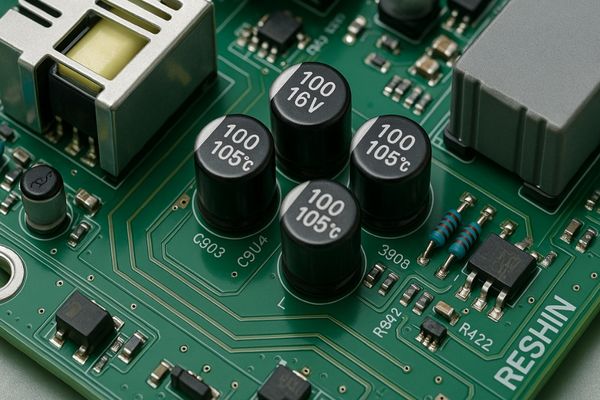

We use industrial-grade components, including medical-grade power supplies with high-efficiency conversion, robust capacitors rated for high temperatures and long lifespans, and durable panel driver boards. These elements are specifically selected to withstand the electrical and thermal stress of continuous operation without performance degradation.

A monitor’s long-term stability begins with its core components. Unlike consumer-grade displays designed for intermittent use, our surgical monitors are built from the ground up for continuous operation. The foundation of this reliability is the medical-grade power supply unit (PSU)4. These PSUs provide clean, stable power and are designed to operate with high efficiency, which minimizes waste heat and reduces stress on all downstream electronics. We pair these with high-endurance, solid-state capacitors5 that are rated for extended lifespans at higher operating temperatures. Standard capacitors are often the first components to fail in electronics under constant load, but our selected components maintain their performance for tens of thousands of hours. The MS247SA, a 24-inch FHD monitor6, is engineered with this philosophy. Its internal circuit boards use thicker copper traces and a robust substrate to manage electrical loads and dissipate heat effectively. Every component, from the video processor to the panel driver board, is chosen for its proven durability in demanding industrial applications, not just for its initial performance. This comprehensive approach to component selection ensures that the monitor provides consistent, reliable service in high-throughput environments where equipment is expected to run without interruption.

How does advanced thermal management prevent overheating during 24/7 use?

You have felt the heat radiating from a monitor during a long surgery. This is a clear sign of potential failure, and overheating can cause image artifacts or a complete shutdown when you need the display most.

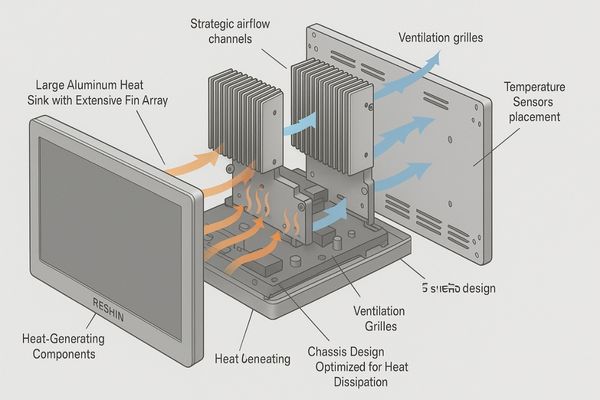

Our monitors use a passive cooling system with oversized aluminum heat sinks, strategic internal airflow channels, and temperature sensors. This design efficiently dissipates heat from critical components like the CPU and power supply without fans, preventing overheating, ensuring silent operation, and maintaining performance.

Heat is the primary enemy of electronic reliability. Continuous operation generates a significant thermal load that can degrade components and lead to performance issues like image flickering, color shifts, or even total system failure. To combat this, we utilize an advanced passive thermal management system7. We deliberately avoid using cooling fans, which are common points of failure, create noise, and can circulate airborne pathogens in a sterile operating room. Instead, our design relies on natural convection. We place large, custom-designed aluminum heat sinks8 in direct contact with the main heat-generating components, such as the central processor and power regulation modules. These heat sinks draw thermal energy away from the sensitive electronics. The monitor’s chassis and internal layout are then engineered to create strategic airflow channels. Vents are carefully positioned to allow cool air to enter from below and hot air to naturally rise and exit from above, creating a silent and continuous cooling cycle. The MS270P surgical display is a prime example of this design, where its chassis is optimized to maximize surface area for heat dissipation, making it ideal for lengthy procedures. This fanless design9 ensures silent operation and long-term reliability without compromising on cooling performance.

Comparison of Cooling Systems in Medical Environments

| Feature | Fan-Based Cooling | Reshin Passive Cooling |

|---|---|---|

| Noise Level | Audible noise (30-45 dB) | Silent operation (0 dB) |

| Reliability | Fans are mechanical points of failure | No moving parts, higher reliability |

| Infection Control | Circulates airborne dust and pathogens | Does not disturb airflow, easier to sterilize |

| Maintenance | Fans require cleaning and eventual replacement | Maintenance-free |

| Power Consumption | Higher due to fan operation | Lower energy consumption |

Do Reshin monitors use special backlight technologies to reduce wear over time?

Over time, you notice your older monitors are not as bright as they used to be. This gradual dimming forces you to strain your eyes and can compromise the visibility of critical anatomical details during surgery.

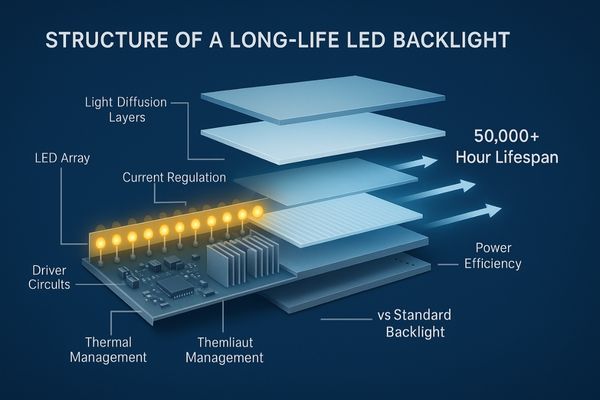

Yes, we use long-life LED backlights with advanced driving circuits that operate the LEDs below their maximum rating to reduce stress and slow brightness decay. This ensures consistent luminance over a lifespan exceeding 50,000 hours, far beyond that of consumer-grade displays.

A monitor’s brightness is not infinite; all backlights degrade over time, leading to a dimmer image. This phenomenon, known as luminance decay10, can significantly shorten the useful life of a surgical display. We address this challenge by focusing on the longevity of our LED backlight systems11. First, we select high-quality LED components that are rated for over 50,000 hours of operation, which translates to more than five years of continuous 24/7 use. However, the more critical element is our advanced driving circuitry. Instead of running the LEDs at their maximum power to achieve a high peak brightness, we engineer our systems to operate them at a more conservative level, typically around 80-90% of their capacity. This simple but effective technique dramatically reduces the electrical and thermal stress on the LEDs, which is the primary cause of their degradation. The MS275P, a 27-inch 4K monitor, utilizes this technology to ensure its brilliant, high-resolution image remains consistent for years. This approach not only extends the backlight’s lifespan but also contributes to greater energy efficiency12 and reduced internal heat, which further enhances the overall reliability of the entire system. The result is a much flatter brightness curve over time, providing a consistent and dependable visual experience throughout the monitor’s service life.

How does real-time calibration maintain consistent image quality?

You’re reviewing a case with a colleague, and the image looks different on their monitor than on yours. This inconsistency in image quality erodes diagnostic confidence and can lead to misinterpretations.

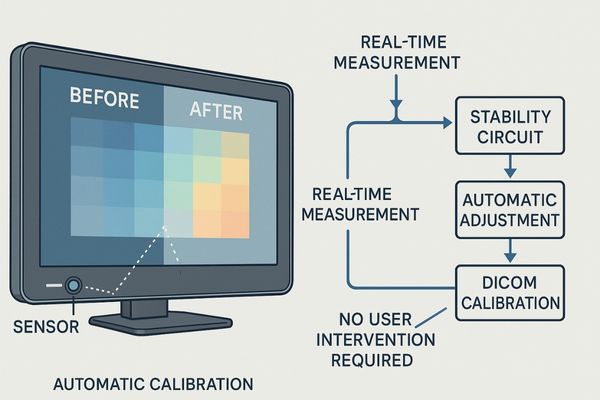

Our monitors integrate a front-facing sensor and a stability system that continuously monitor the backlight’s luminance and color output. This system automatically adjusts the display in real-time to counteract any drift, ensuring consistent brightness and adherence to DICOM or other color standards 24/7.

A monitor’s image quality can drift from its factory settings due to factors like warm-up time, ambient temperature changes, and backlight aging. In a medical setting, this inconsistency is unacceptable. To solve this, we build an automated, real-time calibration system13 directly into our monitors. This system consists of an integrated sensor, often placed discreetly in the front bezel, which periodically measures the light output of the screen. A dedicated stability circuit then compares this measurement against the factory-calibrated reference standard, such as the DICOM Part 14 grayscale curve14 or a specific color profile. If any deviation is detected, the system instantly and automatically adjusts the backlight and video processing engine to bring the image back into perfect alignment. This entire process happens continuously in the background without any user intervention. The MS321PB, a 32-inch 4K surgical monitor, features this technology to provide an unwavering level of image consistency15. For complex specialties like neurology or cardiology where subtle image details are critical, this ensures that the display surgeons rely on is always accurate, from the first minute of operation to the last.

Comparison of Monitor Calibration Methods

| Method | Manual Calibration | Reshin Real-Time Calibration |

|---|---|---|

| Process | Requires external sensor and manual adjustment | Fully automatic, internal sensor |

| Frequency | Periodic (e.g., monthly, yearly) | Continuous, real-time monitoring |

| Consistency | Can drift between calibrations | Consistently accurate at all times |

| Downtime | Requires taking monitor out of service | Zero downtime required |

| Operator Skill | Requires a trained technician | No user action needed |

What certifications validate Reshin monitors’ suitability for continuous medical operation?

You need to present a purchase justification to your hospital’s procurement committee. Without the right certifications, your request for new, reliable monitors will be rejected, leaving your OR with outdated equipment.

Our monitors are validated by essential medical certifications, including IEC 60601-1 for basic safety and essential performance, and IEC 60601-1-2 for electromagnetic compatibility (EMC). These certifications confirm their suitability for continuous, safe operation within the demanding medical environment.

Certifications are more than just formalities; they are documented proof that a device has undergone and passed rigorous testing for safety, reliability, and performance in a clinical setting. We subject our surgical monitors16 to the most stringent international standards to validate their fitness for 24/7 operation. The most critical of these is IEC 60601-1, the globally recognized standard for the basic safety and essential performance of medical electrical equipment. This certification covers risks such as electrical shock, fire, and mechanical hazards, ensuring the monitor is fundamentally safe for use in a patient environment. Equally important for a modern OR is IEC 60601-117-2, which governs electromagnetic compatibility (EMC)18. This standard ensures that the monitor does not emit harmful electromagnetic interference that could affect other sensitive devices and that it is not susceptible to interference from them. The MS550P, our 55-inch 4K large-format display, carries these certifications, providing hospital administrators and technical staff with the confidence that it can be safely integrated into a complex electronic ecosystem. Compliance with these standards is a non-negotiable part of our design process, validating that our monitors are not only high-performing but also fundamentally safe and reliable for continuous medical use.

Conclusion

We achieve 24/7 reliability through durable components, advanced cooling, stable backlights, and real-time calibration, all validated by key medical certifications. This design philosophy ensures dependable performance for modern healthcare.

-

Explore this link to understand the essential features that make surgical displays reliable for continuous use in medical settings. ↩

-

Learn about the importance of thermal systems in maintaining the performance and longevity of surgical displays in demanding environments. ↩

-

Discover the calibration technologies that ensure surgical monitors deliver consistent and accurate image quality over time, crucial for medical professionals. ↩

-

Explore how medical-grade PSUs enhance reliability and performance in surgical monitors, ensuring continuous operation and stability. ↩

-

Learn about the advantages of high-endurance capacitors in electronics, particularly in demanding environments, for longevity and performance. ↩

-

Discover essential features of 24-inch FHD monitors tailored for medical applications, ensuring optimal performance and reliability. ↩

-

Explore this resource to understand how passive thermal management systems enhance electronic reliability without the need for fans. ↩

-

Learn about the effectiveness of aluminum heat sinks in dissipating heat and ensuring optimal performance in electronic devices. ↩

-

Discover the advantages of fanless designs, including noise reduction and increased reliability, in various electronic applications. ↩

-

Understanding luminance decay is crucial for maintaining display quality over time. Explore this link to learn more about its impact on monitors. ↩

-

Discover the technology behind LED backlight systems and how they enhance display longevity and performance. This resource is invaluable for tech enthusiasts. ↩

-

Learn about the advantages of energy efficiency in monitors, including cost savings and environmental impact. This knowledge is essential for informed purchasing decisions. ↩

-

Explore this link to understand how automated calibration systems enhance monitor performance and image quality, especially in critical settings. ↩

-

Learn about the DICOM Part 14 grayscale curve to appreciate its role in ensuring accurate medical imaging and calibration standards. ↩

-

Discover why maintaining image consistency is crucial in medical environments, impacting diagnosis and patient care. ↩

-

Discover the essential features and certifications of surgical monitors to ensure safety and reliability in medical environments. ↩

-

Understanding IEC 60601-1 is crucial for ensuring medical devices meet safety and performance standards. Explore this link for in-depth insights. ↩

-

Learn about EMC’s role in preventing interference between medical devices, ensuring safe and effective operation in clinical settings. ↩