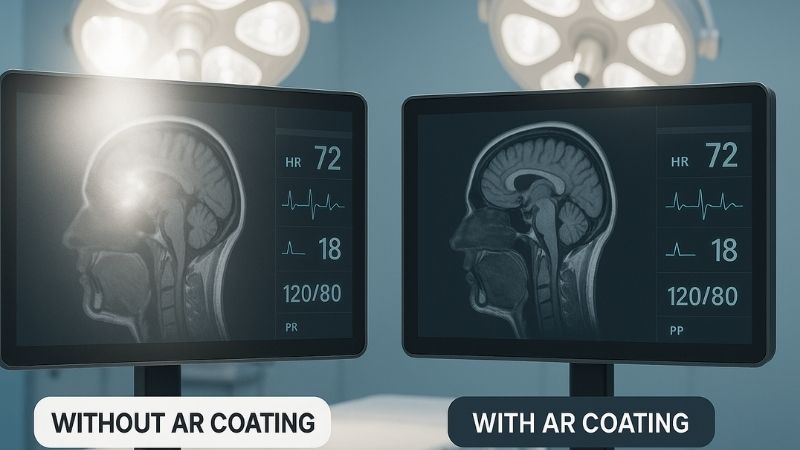

Ever struggled to see a medical display clearly because of harsh operating room lights? This glare can hide critical details. It makes a surgeon’s job even harder.

Medical display coatings are chosen based on criteria like anti-reflection, chemical resistance, antimicrobial properties, and compliance with international safety standards. These ensure image clarity, durability, and patient safety in demanding healthcare environments.

Choosing the right coating for a medical display1] is a very serious business. It’s not just about making the screen look good. It’s about safety, clarity, and durability. As someone working with Reshin, a specialist monitor manufacturer, I’ve seen how much thought goes into these choices. Our president, Martin, always emphasizes how crucial these details are, especially with his background in surgical imaging2. Let’s explore the key factors that guide us and other manufacturers in selecting these vital materials. Dr. Amy Chen, who ensures precise performance, would definitely be interested in these aspects.

Why is anti-reflective coating essential in surgical display environments?

Do bright surgical lights often wash out the image on your medical displays? This makes it hard to see vital information. Such reflections can compromise surgical precision.

Anti-reflective (AR) coating is essential because it reduces glare from strong ambient lighting, like surgical lamps. This enhances image contrast and clarity. It allows surgeons to see critical details without straining their eyes.

Let’s dive deeper into why AR coatings3 are so important. Operating rooms are brightly lit environments by necessity. Surgeons need excellent illumination to perform complex procedures. However, this intense lighting can create strong reflections and glare on display screens. Imagine trying to see fine details on a monitor when a bright light is shining directly onto it – it’s very difficult. This is where high-quality anti-reflective coatings4 come into play. My first insight highlights this perfectly: without AR coating, strong surgical lighting5 degrades image clarity.

These coatings work by using thin layers of specific materials applied to the screen surface. These layers are designed to manipulate light waves in a way that minimizes reflection. Think of it like noise-canceling headphones, but for light. The result is a screen that remains clear and easy to read, even under direct, intense lighting. This significantly reduces eye strain for the surgical team, who might be looking at these displays for many hours. More importantly, it ensures that critical visual information – like the view from an endoscope or vital patient data – is always clearly visible. At Reshin, we understand that enhancing visual precision is key to supporting successful surgical outcomes. That’s why we prioritize effective AR coatings on our surgical displays.

How do medical-grade coatings ensure chemical resistance and safety?

Are you worried that cleaning medical displays with harsh disinfectants might damage them? This is a common concern. Hospital environments require rigorous cleaning protocols.

Medical-grade coatings are specifically chosen for their ability to withstand frequent cleaning with strong chemical disinfectants. This ensures the display’s surface integrity is maintained. It also protects internal components and ensures long-term operational safety.

Let’s explore the chemical resistance6 aspect. In any healthcare setting, especially operating rooms and intensive care units, infection control is a top priority. This means equipment, including medical displays, must be cleaned and disinfected regularly. The cleaning agents used are often quite harsh – think alcohol-based solutions, hydrogen peroxide, or chlorine-based disinfectants. If a display’s coating isn’t up to the task, these chemicals can cause it to degrade, crack, become cloudy, or even peel off. This not only looks bad but can also compromise the display’s functionality and safety. My second insight points this out directly: displays must resist harsh disinfectants.

At Reshin, when we select coating materials, we pay very close attention to their chemical resistance. The materials undergo rigorous testing. We expose them to a range of common hospital-grade disinfectants7 to see how they hold up over time with repeated applications. The goal is to choose coatings that maintain their optical clarity8 and physical integrity even after many cleaning cycles. This is vital for ensuring the longevity of the display and, more importantly, for maintaining a safe environment for patients and staff. If a coating breaks down, it could potentially expose internal electronics or create a surface that’s harder to clean effectively, which is unacceptable in a medical environment. This diligence ensures that Reshin displays can be a reliable part of any infection control protocol.

What role does antimicrobial coating play in infection control?

Do you consider the surfaces of medical equipment as potential sources of infection? In high-risk areas, every surface matters. Reducing microbial presence is always a goal.

Antimicrobial coatings on medical displays help inhibit the growth of bacteria and other microbes on the screen surface. This provides an additional layer of protection against cross-contamination. It supports overall hygiene standards in critical care areas.

Let’s look closer at antimicrobial coatings9. Hospital-acquired infections (HAIs) are a serious concern worldwide. Surfaces that are frequently touched, known as high-touch surfaces10, can become reservoirs for pathogens. Medical displays, especially those with touchscreens or those frequently adjusted, fall into this category. While regular cleaning and disinfection are the primary defense, antimicrobial coatings can offer an added layer of continuous protection. My third insight mentions that these coatings help prevent microbial growth, which is critical in ICUs and ORs.

These coatings typically incorporate an agent, like silver ions or specific polymers, that is toxic to microbes but safe for humans. This agent is embedded within or bonded to the coating material. It works by disrupting the cellular functions of bacteria or inhibiting their ability to reproduce on the surface. It’s important to understand that antimicrobial coatings are not a substitute for proper cleaning and disinfection procedures. Instead, they are a supplementary measure. They help to keep the microbial load down between cleanings. Some Reshin monitors, in line with our commitment to advancing medical display technology and supporting hygiene, already feature such coatings. It’s one more way we try to contribute to a safer healthcare environment, something that Dr. Amy Chen, who is deeply involved in operating theatre equipment, would value.

Which international standards guide the selection of coating materials?

Are you aware of the strict rules that govern materials used in medical devices? These regulations are in place for safety. Compliance is not optional; it’s essential.

The selection of coating materials for medical displays is guided by several international standards. These include ISO 10993 for biocompatibility, RoHS for hazardous substance limits, and REACH for chemical safety. Adherence ensures coatings are safe and environmentally responsible.

Let’s delve into these important standards. Manufacturing medical devices, including displays, is a highly regulated field. Patient safety is the utmost priority. Therefore, the materials used, especially those that might come into contact with patients or medical staff, or that are used in a clinical environment, must meet strict criteria. My fourth insight lists some key standards:

- ISO 10993 (Biological evaluation of medical devices): This is a series of standards that outlines how to assess the biocompatibility of medical devices and their component materials. It ensures that materials do not cause adverse reactions (like toxicity, irritation, or allergic responses) when they interact with the human body or biological systems. For display coatings, this is crucial, as staff will be touching these screens.

- RoHS (Restriction of Hazardous Substances Directive): Originating in the European Union, RoHS restricts the use of specific hazardous materials found in electrical and electronic products. Common restricted substances include lead, mercury, cadmium, and certain flame retardants. Compliance ensures products are safer for users and the environment, especially during disposal.

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): This is another EU regulation, but its impact is global. REACH aims to improve the protection of human health and the environment through better and earlier identification of the intrinsic properties of chemical substances. Companies must register the chemicals they use and demonstrate their safe use.

Here’s a table summarizing their focus:

| Standard | Full Name | Main Focus | Relevance to Coatings |

|---|---|---|---|

| ISO 10993 | Biological evaluation of medical devices | Ensuring materials are safe for human contact/interaction (biocompatibility) | Coatings must not cause skin irritation or toxic effects. |

| RoHS | Restriction of Hazardous Substances Directive | Limiting specific harmful substances in electronics | Coatings must not contain restricted heavy metals, etc. |

| REACH | Registration, Evaluation, Authorisation and Restriction of Chemicals | Managing risks from chemicals throughout their lifecycle | Ensuring chemicals used in coatings are safe and registered. |

At Reshin, we take these standards very seriously. It’s part of our mission to provide high-quality and safe display solutions. Adhering to these international guidelines ensures that our products meet the highest safety and environmental benchmarks, which is a fundamental expectation in the medical field.

How does Reshin optimize coating selection for durability and clinical usability?

Are you looking for medical displays that are not only clear but also tough enough for daily hospital use? Durability is key. It ensures a long service life and reliable performance.

Reshin carefully balances durability with clinical performance in its coating choices. We use materials like anti-glare tempered glass and apply protective antimicrobial layers. This approach enhances both the resilience and the usability of our monitors in demanding clinical settings.

Let’s look at how we at Reshin put all these considerations together. Selecting the right coating isn’t just about meeting one criterion; it’s about finding the optimal balance for the specific application. As a specialist monitor manufacturer, we draw on Martin’s deep experience in surgical imaging to make informed decisions. Our goal is to create displays that are not only visually superb but also robust and practical for the demanding healthcare environment. My fifth insight mentions our approach: balancing durability and performance, using anti-glare tempered glass11 and antimicrobial layers in models like the MS550P.

For durability, we often opt for materials like chemically strengthened or tempered glass, especially for screens that might be subject to impacts or frequent touching. This type of glass is much more resistant to scratches and breakage than standard glass or plastic. On top of this durable base, we apply specialized coatings. The anti-reflective and anti-glare properties are crucial for visual performance, as we’ve discussed. The chemical resistance ensures the display can withstand rigorous cleaning. And, where appropriate, antimicrobial layers12 add an extra measure of hygiene. For instance, our Reshin MS550P, designed for challenging environments, incorporates these features. We also consider the tactile feel of the coating, especially for touchscreens, ensuring it’s smooth and responsive. It’s a multi-faceted approach, always aiming to enhance both the resilience and the clinical usability of our displays, supporting medical professionals like Dr. Amy Chen in their critical work.

Conclusion

Selecting medical display coatings involves careful consideration of AR properties, chemical resistance, antimicrobial benefits, and adherence to safety standards for optimal clinical performance. For medical displays with expertly engineered coating solutions, contact Reshin at martin@reshinmonitors.com.

- Learning about the best coatings for medical displays can help ensure clarity and durability in critical environments. ↩

- Exploring the relationship between surgical imaging and medical display design can provide insights into improving patient outcomes. ↩

- Explore how AR coatings enhance visibility and reduce glare in operating rooms, crucial for successful surgeries. ↩

- Learn about the advantages of anti-reflective coatings in improving image clarity and reducing eye strain for surgeons. ↩

- Discover the impact of surgical lighting on display screens and the importance of clear visuals during procedures. ↩

- Understanding chemical resistance is crucial for ensuring the longevity and safety of medical displays in healthcare settings. ↩

- Learn about hospital-grade disinfectants to appreciate their role in infection control and the need for resistant materials in medical displays. ↩

- Explore the significance of optical clarity in medical displays for effective monitoring and patient safety in healthcare environments. ↩

- Explore this link to understand the science behind antimicrobial coatings and their role in infection control, especially in healthcare settings. ↩

- Discover the significance of high-touch surfaces in healthcare and how they contribute to the spread of infections, along with preventive measures. ↩

- Explore how anti-glare tempered glass enhances visibility and durability in healthcare settings, ensuring optimal performance for medical displays. ↩

- Learn about the importance of antimicrobial layers in medical devices and how they contribute to patient safety and hygiene. ↩