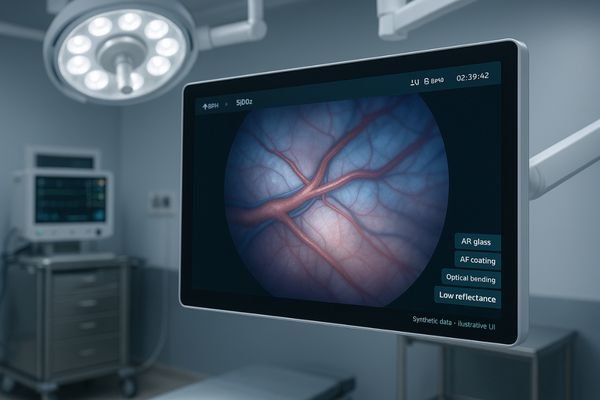

Glare from surgical lights can obscure critical anatomical details on a monitor, creating reflections that compromise precision. This forces surgeons to adjust their position, wasting time and focus.

This guide explains why anti-reflection (AR) and anti-fingerprint (AF) coatings are essential. We will cover how optical bonding enhances AR, how to evaluate coatings in the OR, their impact on hygiene and workflow, C-arm video integrity, and key integration details.

Recommended surgical monitors with AR/AF (2025)

• Reshin MS321PB — AR protective glass + optical bonding; 12G-SDI 2160p60; multi-view

• Sony LMD-X3200MD — Scratch-resistant anti-reflection panel structure for bright ORs

• FSN FM-E3203D — Surface treatment: anti-reflection + anti-fingerprint

In the modern operating room, visual clarity is not just a feature—it is a prerequisite for safety and efficiency. A monitor’s ability to overcome the challenging lighting conditions of the OR is paramount. While a high contrast ratio1 on a spec sheet looks impressive, it is the performance in the actual environment that matters. This is where advanced surface treatments like anti-reflection and anti-fingerprint coatings2 become critical. They directly address the real-world problems of glare and contamination, enhancing a surgeon’s ability to see clearly and ensuring the equipment remains ready for every procedure.

Why AR & AF Coatings Matter in the OR (Perceived Contrast & Hygiene)

Reflections from overhead lights can veil fine structures on-screen, while fingerprints and smudges create distracting blemishes. This forces clinicians to constantly adjust their view, impacting focus and procedural flow.

AR coatings dramatically improve perceived contrast in bright ORs by cutting glare, preserving detail. AF coatings reduce smears from gloves and gels, ensuring consistent visibility and faster turnovers, which directly supports infection control protocols.

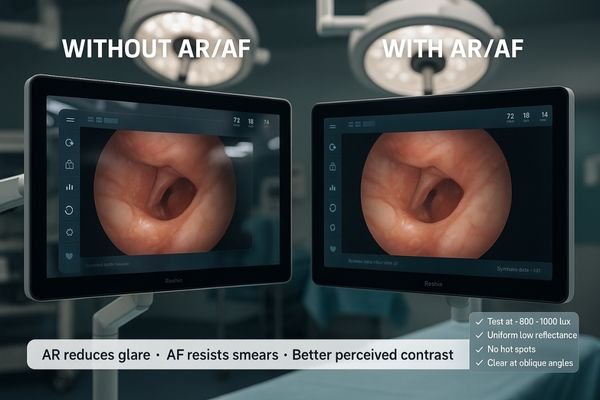

AR in-room checklist

• Test under your typical surgical lighting (≈800–1000 lux)

• Check center and corners for uniform low reflectance (no hot spots)

• Confirm clarity at oblique boom angles (no veiling glare)

• Look for dull, neutral reflections (avoid mirror-like highlights)

The practical value of AR and AF coatings3 extends far beyond a cleaner-looking screen. In a brightly lit operating room, often illuminated at 800–1000 lux, specular reflections are a significant problem. An AR coating works to minimize these reflections, allowing the surgeon to see the image on the screen rather than a reflection of the light source. This directly improves the perceived contrast, making the edges of tissues and the definition of fine structures more apparent. The on-paper contrast ratio of the panel becomes secondary to its real-world performance under intense lighting. Similarly, an oleophobic AF coating4 is not just about aesthetics. It provides measurable ROI for a busy surgical department. By resisting smudges from gloved hands and repelling surgical gels, it drastically reduces the time and effort required for wipe-downs between cases. This helps ensure tight turnover schedules are met and that image quality remains consistent for every procedure throughout the day.

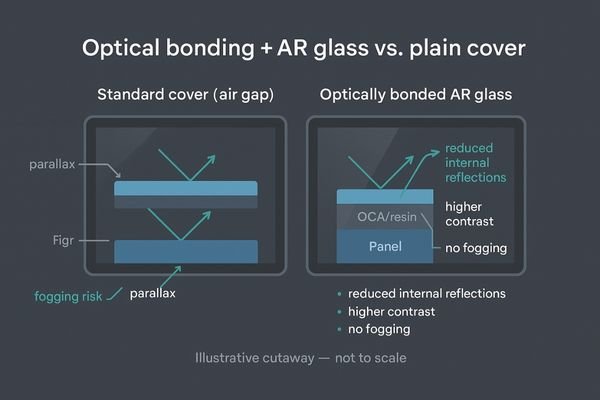

Optical Bonding + AR Glass vs. Plain Cover (Glare, Fogging, Cleanability)

A standard monitor has an air gap between the panel and its protective cover. This gap creates internal reflections that reduce contrast and can trap moisture, leading to fogging.

Optically bonded AR glass eliminates the air gap, drastically reducing internal reflections and parallax error. This enhances contrast, prevents fogging, and creates a durable, easy-to-clean surface ideal for the OR environment.

Optical bonding5 is a manufacturing process where a layer of transparent resin is used to completely fill the air gap between the LCD panel and the outer protective glass. This single step delivers multiple clinical advantages. First, it virtually eliminates internal reflections. By creating a single optical index, it allows more light from the panel to pass through to the viewer, significantly boosting the effective contrast ratio and perceived image clarity, especially when viewed from an angle. This is particularly valuable for C-arm systems6, where surgeons and technicians view the screen from oblique angles on OR booms. Second, it makes the display impervious to fogging caused by temperature differentials. The solid structure also adds significant durability and impact resistance. Finally, the flush, bonded surface is easier to clean and disinfect. A monitor like the MS321PB integrates optical bonding with AR protective glass, providing a robust solution that delivers superior optical performance and durability tailored to the physical demands of the surgical environment.

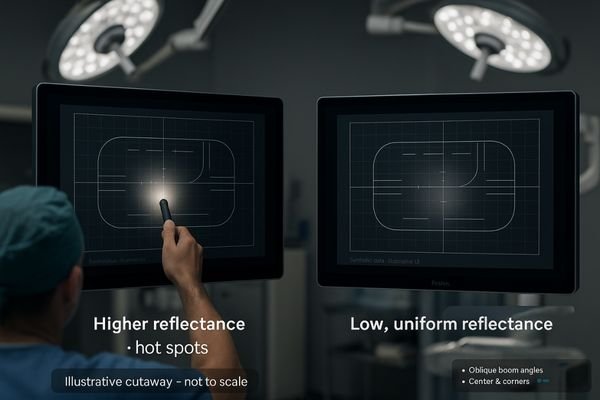

How to Judge “Anti-Reflection” in Practice (Illuminance, Reflectance, Uniformity)

Lab-based reflectance percentages do not tell the whole story. A coating can perform well in a dark room but fail under the intense, multi-angle lighting of a real operating room.

Judge AR performance in your own OR, under your typical surgical lighting. A superior coating provides low, uniform reflectance across the entire screen, eliminating "hot spots" and preserving image clarity from all viewing angles.

Evaluating an AR coating7 requires a practical, in-situ approach. The most effective method is to request an in-room demonstration from vendors. Position the monitor on the surgical boom exactly where it will be used and turn on the surgical lights8 to your typical operating levels. Observe the screen from various angles, paying close attention to the intensity and character of any reflections. A high-quality AR stack, properly tuned for the OR, will produce only a faint, dull reflection with a consistent color, often a subtle purple or green. More importantly, this low level of reflectance should be uniform across the entire surface. If you notice bright "hot spots" or mirror-like images of the light fixtures, especially near the center or corners, it indicates the coating is not effectively diffusing the specular glare. This simple, real-world test provides far more valuable information than a spec sheet and reveals how the display will truly perform during a procedure.

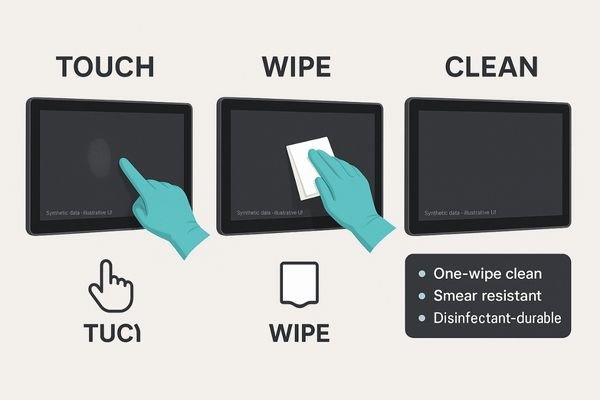

Anti-Fingerprint Coatings in Daily OR Workflows (Smudge Control & Disinfectants)

During a procedure, screens are frequently touched by gloved hands, leaving behind smudges and residue. If difficult to clean, this residue can build up and degrade image quality over time.

An effective AF coating resists smudges and allows for quick, easy wipe-downs with common hospital disinfectants. This ensures consistent image clarity and helps staff adhere to strict infection control SOPs without adding procedural delays.

AF hygiene checklist

• One-wipe clean with approved disinfectants

• No persistent smears from gloves/gels

• Coating durability after repeated cleaning cycles

An Anti-Fingerprint (AF) coating9 is an oleophobic (oil-repelling) layer that creates a very low-friction surface. In the OR, this translates into two key workflow benefits. First, it minimizes the adhesion of fingerprints, smears from surgical gels, and other contaminants. Instead of a large, greasy smudge, contact often leaves only a faint, easily removable mark. Second, it simplifies the cleaning process between cases. Staff can wipe the screen clean with approved disinfectants in a single, quick pass, rather than having to scrub at stubborn residue. This not only saves valuable time during room turnover but also ensures a higher level of hygiene compliance. A good AF coating must also be durable enough to withstand repeated cleaning10 with the chemical disinfectants used in hospitals. This durability ensures the coating’s benefits do not degrade over the monitor’s lifespan, providing a consistent, easy-to-maintain surface that supports both optical clarity and infection control.

C-arm Video Integrity under AR Glass (12G-SDI, 2160p60, EMI)

A pristine optical surface is meaningless if the video signal itself is compromised. The high-resolution, high-frame-rate video from modern C-arms and endoscopy systems demands a robust and reliable signal path.

To maintain video integrity, pair superior optics with a 12G-SDI input. This combination delivers uncompressed, low-latency 4K 60Hz video and superior EMI resistance, which is essential for artifact-free imaging from C-arms.

The AR glass is the final stage in the imaging chain, but the signal must arrive intact. For demanding 4K 60Hz video from C-arm or endoscopic sources, a 12G-SDI (Serial Digital Interface)11 connection is the gold standard. Unlike HDMI, which is a consumer standard, SDI is designed for professional broadcast and medical environments. It uses a single coaxial cable with a locking BNC connector, preventing accidental disconnection. This single cable can carry an uncompressed 2160p60 signal over long distances without the need for unreliable extenders. Furthermore, the shielding of coaxial cables provides excellent resistance to electromagnetic interference (EMI)12, a critical factor in an OR filled with various electronic devices. This ensures that the pristine, low-latency video from the imaging source is delivered to the panel without artifacts, corruption, or signal dropouts. A monitor equipped with both optimal AR glass and a 12G-SDI input provides a true end-to-end solution for video integrity.

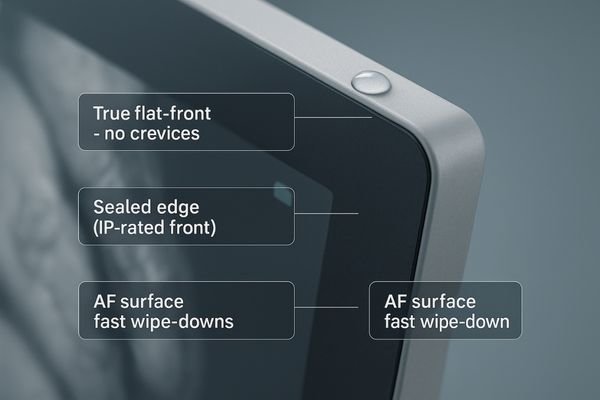

Integration & Mounting Details for OR Booms (Flat-Front, Seals, I/O Mix)

Monitors mounted on OR booms face unique physical and hygienic challenges. Crevices can trap contaminants, and poor cable access can complicate installation and maintenance.

A flat-front, sealed-edge design is crucial for infection control. It eliminates residue traps and, when paired with an AF coating, allows for fast, effective wipe-downs. A versatile I/O mix simplifies integration with diverse OR equipment.

The physical design of a surgical monitor is as important as its electronic performance. A "true flat" front surface, where the protective glass extends from edge to edge without a raised bezel, is a key feature for infection control. This design eliminates the crevices that can trap fluids and contaminants, making the entire front surface easy to wipe down. When this is combined with an IP (Ingress Protection) rating13 that certifies the front is sealed against liquids, it creates a surface that supports the most stringent cleaning protocols. This helps distributors and hospital integrators meet infection-control SOPs without requiring special staff training. Additionally, a thoughtfully designed input/output (I/O) panel with a mix of modern and legacy ports (like SDI, DisplayPort, and DVI) ensures the monitor can be easily integrated with both new and existing endoscopy towers, C-arms, and PACS systems, simplifying the installation and upgrade process for an entire fleet.

| Integration Feature | Benefit for OR Booms |

|---|---|

| True Flat-Front Design | Eliminates crevices, simplifying cleaning and improving hygiene. |

| IP-Rated Front Seal | Protects internal components from liquids during cleaning and use. |

| Versatile I/O Ports | Ensures compatibility with a wide range of surgical imaging equipment. |

| Durable AF Coating | Resists smudges and withstands repeated disinfection for faster turnovers. |

Conclusion

The best surgical monitors are defined not by specifications in a vacuum, but by their ability to deliver clear, artifact-free images in the challenging environment of the operating room. 🔬

👉 For advanced surgical display solutions and tailored recommendations, contact martin@reshinmonitors.com.

-

Learn about the significance of high contrast ratios in improving visibility and efficiency during surgeries. ↩

-

Explore how these coatings enhance visual clarity and safety in surgical environments. ↩

-

Explore how AR and AF coatings enhance visibility and efficiency in surgical settings, ensuring optimal performance. ↩

-

Learn how oleophobic AF coatings reduce maintenance time and improve image quality, crucial for busy surgical departments. ↩

-

Explore this link to understand how optical bonding enhances display performance and durability, crucial for medical applications. ↩

-

Discover how optical bonding improves image clarity and usability in C-arm systems, essential for surgical precision. ↩

-

Understanding AR coating evaluation can enhance your surgical display experience and ensure optimal performance. ↩

-

Exploring the impact of surgical lights on AR coatings can help you make informed decisions for better visibility during procedures. ↩

-

Explore this link to understand how AF coatings enhance hygiene and efficiency in healthcare settings. ↩

-

Learn about the durability of coatings to ensure long-lasting hygiene and maintenance in medical facilities. ↩

-

Explore this link to understand the advantages of 12G-SDI in professional video applications. ↩

-

Learn about EMI’s impact on video quality and how to mitigate its effects in your setup. ↩

-

Learn about the importance of IP ratings in ensuring the safety and durability of medical equipment against liquids. ↩