Radiologists routinely miss subtle breast tissue abnormalities when viewing mammograms on improperly calibrated displays. Could your diagnostic monitors be silently compromising detection rates without showing obvious signs of failure?

DICOM curve drift in mammography diagnostic monitors can distort grayscale consistency and compromise lesion visibility. This article explores the ten most common causes of DICOM drift and outlines proven strategies to prevent it across professional breast imaging environments.

As part of Reshin’s global calibration engineering team, we’ve supported hospitals worldwide in resolving DICOM compliance challenges. Below, we detail the ten most frequent causes of DICOM curve drift specific to mammography diagnostic monitors — and practical ways to prevent them.

What Causes DICOM Curve Drift in Mammography Diagnostic Monitors?

Radiologists often notice inconsistent image presentation across viewing stations but may not understand the underlying technical causes. What specific factors drive mammography displays away from their calibrated DICOM state?

DICOM curve drift primarily results from panel aging, backlight decay, and temperature-dependent luminance changes. Over time, the photometric characteristics of LCD panels diverge from their original calibration, especially in high-brightness mammography displays. Regular usage cycles, varying ambient conditions, and component wear gradually distort grayscale response.

Component-Level Factors in DICOM Calibration Drift

At the hardware level, several mechanisms contribute to DICOM curve drift1:

- LCD Panel Aging – The liquid crystal material gradually changes its electro-optical properties, altering its voltage-transmission relationship.

- Backlight Degradation – LED backlights lose luminance output over time, typically 10–15% per 10,000 operating hours.

- Electronic Drift – Voltage references, amplifiers, and converters experience shifts over time and temperature.

- Optical Interface Stress – Mechanical fatigue and temperature cycling degrade optical coupling between layers.

The cumulative effect manifests as grayscale inconsistency — particularly critical in mammography where subtle density differences drive diagnostic accuracy.

The Mammography DICOM Challenge in Diagnostic Monitors

Mammography displays face unique DICOM drift challenges due to:

| Factor | Impact on DICOM Compliance | Diagnostic Significance |

|---|---|---|

| High Brightness | Accelerated backlight aging | Critical for microcalcification detection |

| Extended Luminance Range | Complex calibration curve | Distinguishing overlapping tissues |

| Low-Contrast Detection | Sensitive to dark-level drift | Essential for subtle lesion visibility |

| Continuous Reading | Thermal stabilization difficulty | Impacts interpretive consistency |

These combined factors make mammography displays far more prone to DICOM drift than general diagnostic displays, demanding tighter QA control.

How Does Ambient Light Affect DICOM Consistency in Mammography Reading Rooms?

Many radiology departments underestimate environmental influence on DICOM performance. How exactly does the reading room affect DICOM accuracy?

Ambient illumination alters perceived luminance contrast and affects DICOM compliance. Excessive light reflection or glare distorts grayscale mapping, especially at low luminance levels crucial for microcalcification detection. Mammography reading rooms should maintain illumination below 20 lux with controlled reflection and anti-glare surfaces.

Environmental Control for DICOM Consistency in Mammography Reading Rooms

To maintain consistent DICOM performance2:

- Maintain ambient light between 15–20 lux.

- Use neutral gray walls (Munsell N8) to stabilize reflections.

- Avoid direct light within the radiologist’s field of view.

- Keep consistent lighting throughout the day.

- Position displays perpendicular to light sources.

These practices align with American College of Radiology recommendations for stable mammography interpretation environments.

Why Is Regular Luminance Calibration Critical for Mammography Displays?

Calibration frequency remains a debated topic. Why is regular luminance calibration3 particularly vital for mammography diagnostic monitors?

Luminance calibration ensures every grayscale level aligns with the DICOM GSDF curve. Drift causes inconsistent contrast across studies. For mammography—where subtle density variations indicate pathology—precise calibration every 1–3 months is essential.

Calibration Standards for Mammography DICOM Compliance

| Parameter | General Radiology | Mammography |

|---|---|---|

| Maximum Luminance | ≥350 cd/m² | ≥420 cd/m² |

| Luminance Ratio | ≥250:1 | ≥350:1 |

| GSDF Conformance | ±20% | ±10% |

| Calibration Frequency | Quarterly | Monthly–Quarterly |

| Uniformity Tolerance | ±30% | ±15% |

Note: Specific QA intervals and limits should follow applicable local regulations and the latest professional guidelines.

For help establishing a compliant calibration program for mammography diagnostic monitors, contact info@reshinmonitors.com.

What Role Does the Backlight Play in DICOM Stability?

The illumination system behind an LCD panel critically influences calibration stability.

Backlight degradation directly impacts luminance uniformity and DICOM curve alignment. LED modules lose brightness over time due to thermal stress and voltage decay. Premium mammography displays use temperature-compensated LED control and real-time feedback sensors for stable luminance.

Backlight Performance and DICOM Stability in Mammography Displays

High-quality diagnostic displays apply feedback sensors, thermal monitoring, and conservative drive currents to extend backlight life. These features ensure luminance uniformity across the panel—essential for maintaining diagnostic reliability in long-duration breast imaging sessions.

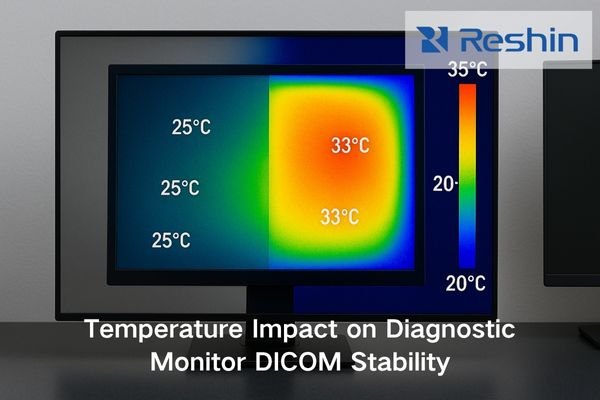

How Do Temperature Variations Affect DICOM Accuracy in Mammography Displays?

Temperature shifts alter LCD liquid crystal behavior and backlight output, causing grayscale response drift. Displays placed near HVAC outlets are especially vulnerable. Maintaining 20–24°C with less than ±2°C variation ensures minimal DICOM deviation and better calibration stability.

Consistent environmental temperature management reduces calibration workload and improves display life.

How Do Built-in DICOM Sensors Prevent Curve Deviation?

Integrated DICOM sensors measure luminance output and auto-adjust the backlight to prevent drift from aging or environment. Dual-sensor redundancy in mammography displays enhances accuracy and ensures compliance without manual recalibration.

Continuous feedback-based calibration reduces manual QA downtime and maintains DICOM conformance within ±5% over thousands of operating hours.

What Maintenance Practices Extend Calibration Stability?

Preventive maintenance4 keeps displays stable between formal recalibrations. Warm-up periods, monthly luminance checks, and quarterly uniformity tests prevent drift.

| QA Activity | Frequency | Purpose |

|---|---|---|

| SMPTE Pattern Review | Daily–Weekly | Quick grayscale visual check |

| Center Luminance | Monthly | Confirm brightness stability |

| Uniformity Assessment | Quarterly | Ensure screen consistency |

| Calibration Verification | Quarterly | Confirm GSDF alignment |

Use medical-grade photometers and maintain NIST-traceable calibration logs for compliance.

How Do Software Updates Influence DICOM Performance?

Firmware and QA software updates modify look-up tables (LUTs) and correction coefficients. Improper updates may desynchronize calibration data, causing visible tone shifts.

Before any update:

- Backup current calibration data.

- Test updates on non-clinical systems first.

- Validate calibration after installation.

Change control is key to maintaining DICOM accuracy across mammography workstations.

How Does Display Uniformity Affect DICOM Compliance in Mammography Imaging?

Uneven luminance introduces localized DICOM deviations. Factory uniformity correction and temperature-compensated circuits ensure consistent luminance across the screen—critical for detecting microcalcifications.

| Test Method | Implementation | Tolerance |

|---|---|---|

| 5-Point Test | Center + Corners | <15% deviation |

| 9-Point Test | Center + Mid-Edges | <15% deviation |

| Uniformity Map | Photometer Heatmap | No hotspot >15% |

| Visual Check | Uniform Gray Field | No visible banding |

Quarterly QA uniformity testing ensures compliance with ACR and MQSA standards (specific limits vary by region).

How Can Manufacturers Minimize DICOM Drift Through Design?

Manufacturers prevent drift using high-stability LED drivers, temperature-compensated circuits, and factory multi-point calibration. Adaptive luminance algorithms and redundant sensors ensure long-term DICOM precision.

Design-Level Stability Strategies for DICOM-Ready Diagnostic Monitors

| Technology | Implementation | Benefit |

|---|---|---|

| Closed-Loop Luminance Control | Real-time adjustment | Maintains brightness stability |

| Predictive Aging Algorithms | Compensate known drift | Reduces manual recalibration |

| Multi-Sensor Systems | Redundant verification | Ensures calibration accuracy |

| Thermal Mapping | Temperature-based correction | Prevents thermal drift |

| Automatic DICOM Verification | Self-test cycles | Continuous compliance |

Reshin diagnostic displays integrate these methods to guarantee reliable long-term DICOM performance in mammography.

Conclusion

DICOM curve drift directly affects diagnostic consistency and lesion detectability in mammography imaging. By combining proactive calibration, environmental control, and built-in stabilization, medical facilities can achieve reliable long-term luminance uniformity and GSDF conformance.

Understanding how backlight stability, thermal management, and software design interact allows radiology departments to prevent drift proactively rather than reactively—ensuring consistent diagnostic performance across every reading session.

Recommended Diagnostic Displays for DICOM Stability

Selecting the right diagnostic monitor is the most effective way to prevent long-term DICOM curve drift and ensure consistent grayscale accuracy in mammography imaging. Reshin’s latest generation of medical-grade displays integrates hardware-level DICOM stabilization, multi-sensor feedback, and advanced luminance compensation to maintain GSDF compliance throughout the monitor’s lifecycle.

| Model | Resolution | Brightness | Key Features | Ideal Use Case |

|---|---|---|---|---|

| MD52G | 5MP (2560×2048) | 1100 cd/m² | Dual front sensors, real-time DICOM auto-calibration, temperature-compensated LED | Mammography and breast tomosynthesis |

| MD45C | 5MP (2560×2160) | 1200 cd/m² | FPGA-based grayscale processing, adaptive drift correction | Precision diagnostic reading rooms |

| MD120C | 12MP (4200×2800) | 1200 cd/m² | Multi-sensor feedback system, enhanced luminance uniformity | Multi-modality breast imaging |

Each Reshin diagnostic display is designed and manufactured under ISO 13485 quality management, ensuring compliance with ACR, FDA, and DICOM GSDF standards. These models deliver exceptional long-term performance and calibration stability — ideal for facilities seeking maximum diagnostic accuracy and minimal maintenance requirements.

Reshin Solutions for Mammography DICOM Stability

Reshin’s diagnostic display series incorporates redundant stabilization systems, thermal compensation, and real-time luminance correction to ensure long-term DICOM precision. Whether upgrading existing diagnostic monitors or developing new imaging systems, our engineering team delivers tailored calibration and QA solutions for mammography applications.

Key Takeaways on Mammography DICOM Calibration

- Regular calibration maintains DICOM GSDF accuracy.

- Temperature and ambient light control prevent drift.

- Built-in sensors automate luminance stabilization.

- Preventive QA extends operational consistency.

- Firmware management preserves LUT integrity.

- Factory multi-point calibration ensures long-term precision.

📧 info@reshinmonitors.com

🌐 https://reshinmonitors.com/

Reshin — China’s Largest Medical-Grade Monitor Manufacturer

-

Understanding DICOM curve drift is crucial for maintaining image quality in mammography. Explore this link to learn more about its causes and solutions. ↩

-

Understanding DICOM performance is crucial for accurate imaging. Explore this link to enhance your knowledge on optimizing DICOM systems. ↩

-

Understanding luminance calibration is crucial for ensuring accurate mammography readings, which can impact patient diagnosis. ↩

-

Understanding preventive maintenance can enhance display performance and longevity, ensuring optimal viewing experiences. ↩