A display’s brightness can fluctuate, hiding critical clinical details. This inconsistency can lead to diagnostic errors. Advanced backlight correction provides the stable luminance needed for clinical confidence.

Reliable medical imaging depends on advanced backlight correction. These systems ensure uniform luminance, provide real-time adjustments, compensate for device aging, and align with strict calibration standards for diagnostic and surgical clarity.

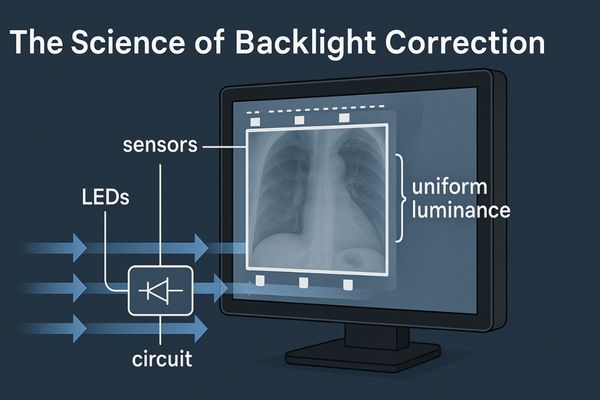

The light-emitting diode (LED) backlight1 is the source of light for all modern LCD monitors. In a consumer display, its job is simply to make the image visible. In a medical display, its role is far more critical. The backlight must deliver a perfectly uniform and stable field of light. Any deviation can alter how an image is perceived, introducing risk into the diagnostic process. Sophisticated correction mechanisms are built into every medical display to control the backlight’s behavior. These systems are essential for ensuring the visual reliability2 that clinicians depend on.

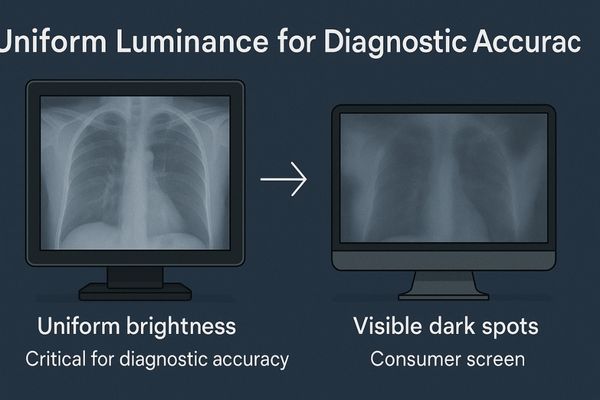

Uniform Luminance is Essential for Diagnostic Accuracy

An uneven screen makes one part of a scan look darker than another. This inconsistency can mask subtle pathologies. Uniform screen luminance ensures a consistently reliable view across the entire image.

Uneven screen brightness can obscure or mimic pathologies. Backlight correction mechanisms create a uniform luminance field across the entire display. This is a fundamental requirement for accurate diagnostic interpretation.

Luminance uniformity refers to the consistency of brightness across the entire surface of the screen. In an ideal display, the center, corners, and edges would all have the exact same luminance value. However, in reality, all LCD panels have some degree of non-uniformity. On a consumer monitor, this can result in visible blotches or dim corners, which is distracting but not critical. On a diagnostic display, this same issue could be catastrophic. A darker area on the screen could obscure a faint nodule, while a brighter spot might wash out subtle tissue texture. Medical displays solve this problem with specialized uniformity correction technology3. During manufacturing, each display is measured at hundreds of points across its surface. A detailed correction map is created and stored in the monitor’s firmware. This system then makes real-time, pixel-level adjustments to counteract any non-uniformity, ensuring a perfectly even luminance field. This feature, present in displays like the MD33G – 3MP Grayscale Diagnostic Monitor, is foundational to providing a trustworthy canvas for interpretation.

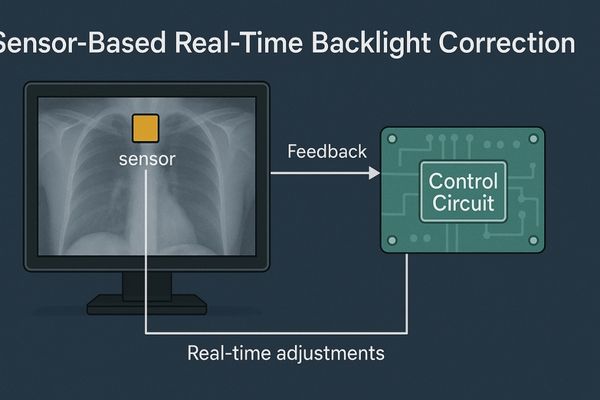

Sensor-Based Backlight Correction Enables Real-Time Adjustment

A monitor’s brightness can drift as it warms up. This subtle change can affect image perception. Integrated sensors provide real-time correction to ensure consistently stable performance.

Built-in sensors continuously monitor the backlight’s output and feed this data to the display’s circuitry. This process allows for real-time adjustments to maintain stable luminance and counteract drift from temperature changes.

Even the most uniform display is subject to performance drift4. As a monitor warms up after being turned on, its backlight output can change. Brightness can also fluctuate with changes in ambient room temperature. While these shifts may be imperceptible to the naked eye, they can move the display out of its calibrated state. To prevent this, medical displays are equipped with internal sensors that provide a continuous feedback loop5. A photodiode is placed near the backlight to constantly measure its light output. If this sensor detects any deviation from the target luminance, it sends a signal to the monitor’s control board. The board then adjusts the power going to the backlight to instantly correct the output. This all happens in real time, without any user intervention. This ensures the display’s brightness remains stable from the moment it is turned on until it is turned off. Displays like the MD22CA – 2MP Diagnostic Monitor feature this technology, providing "walk-away" stability that clinicians can rely on.

| Correction Method | How It Works | Key Benefit |

|---|---|---|

| Manual Calibration | An external sensor is used periodically | Restores accuracy at a single point in time. |

| Sensor-Based Correction | An internal sensor works continuously | Maintains accuracy and stability in real time. |

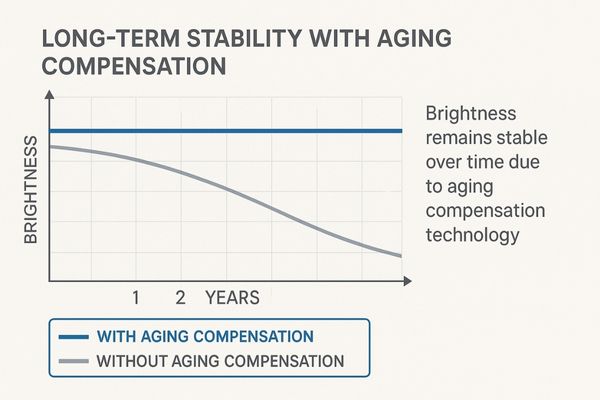

Aging Compensation Maintains Long-Term Display Stability

All displays eventually grow dimmer over time. This natural aging process can slowly degrade diagnostic quality. Aging compensation technology actively counteracts this effect to ensure reliability for years.

A backlight’s light output naturally decreases with thousands of hours of use. Aging compensation mechanisms track this decline and gradually increase power to the backlight. This maintains the monitor’s calibrated brightness level.

The LEDs used in a display’s backlight have a finite lifespan. Over many thousands of hours of operation, their light output will gradually and permanently decrease. Without any intervention, a monitor calibrated to 500 cd/m² when new might only be able to produce 400 cd/m² after a few years of heavy use. This would render it unsuitable for diagnostic work. To solve this, medical displays incorporate an aging compensation system6. This system works in tandem with the internal stability sensor. The monitor’s firmware keeps a log of its operational hours and tracks the long-term trend of its luminance output. As it detects the inevitable decline associated with age, it systematically increases the electrical current supplied to the LEDs. This boost in power compensates for the reduced efficiency of the aging diodes, allowing the display to maintain its target brightness for much longer. This extends the useful clinical life of the monitor, protecting the hospital’s investment and ensuring a lower total cost of ownership7. This feature is a critical component in long-lasting products like our MD85CA.

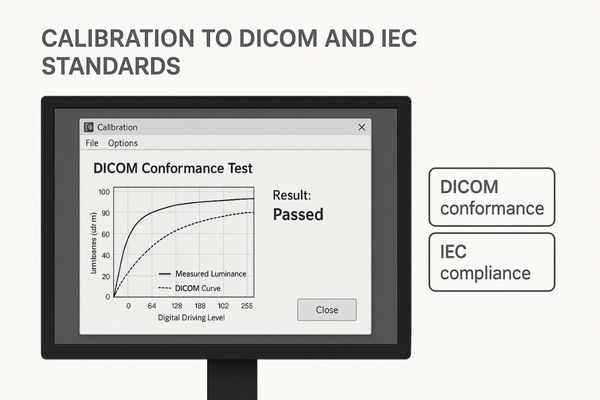

Calibration Protocols Align with DICOM and IEC Standards

An uncalibrated display is a major source of potential diagnostic error. Its grayscale representation is unreliable. Calibration to international standards like DICOM ensures every image is seen correctly and consistently.

Calibration precisely aligns a display’s performance with established standards such as DICOM Part 14 for grayscale and IEC guidelines for quality assurance. This guarantees perceptual consistency across different monitors and locations.

Backlight correction mechanisms are the hardware foundation, but calibration is the process that puts them to work for a specific purpose. For diagnostic imaging, that purpose is defined by standards like DICOM and IEC. DICOM Part 14 defines the Grayscale Standard Display Function (GSDF)8, the universally accepted curve for rendering medical images. Calibration is the process of adjusting a monitor’s backlight and color output to perfectly match this curve. The International Electrotechnical Commission (IEC) provides guidelines for quality assurance, including acceptance testing for new devices and regular constancy testing to ensure they remain in spec. A medical display’s calibration software9 uses an external or built-in sensor to measure the screen’s output. It then uses the internal correction hardware to make fine adjustments until the monitor’s performance precisely aligns with the selected standard. The MD120C – 12MP High-Precision Diagnostic Monitor with AI Calibration even uses AI algorithms to make this process faster and more accurate, ensuring unwavering compliance with these critical clinical standards.

| Standard / Guideline | Primary Focus | Clinical Purpose |

|---|---|---|

| DICOM Part 14 GSDF | Grayscale Display | Ensures consistent image appearance for diagnosis. |

| AAPM TG18 | Quality Control Patterns | Provides test patterns for visual and quantitative evaluation. |

| IEC 62563-1 | Acceptance/Constancy Tests | Defines protocols for verifying display performance over time. |

Advanced Algorithms Optimize Backlight Performance in Surgery

The intense lights of an operating room can wash out a standard monitor screen. Simply turning up the brightness can distort colors. Smart algorithms are needed to optimize the visual experience.

In bright surgical settings, displays must deliver extremely high luminance without sacrificing color accuracy. Advanced backlight algorithms dynamically manage luminance and color channels to provide a clear and true-to-life image.

The visual requirements in an operating room are very different from those in a dark radiology reading room. Surgical displays must contend with extremely high ambient light from powerful overhead lamps. A display must be exceptionally bright to remain clearly visible. However, simply driving the backlight to its maximum level can have negative side effects, such as washing out dark tones and oversaturating colors. This can compromise the surgeon’s ability to distinguish between subtle tissue variations. To address this, advanced surgical monitors10 use sophisticated backlight control algorithms11. Instead of a static backlight level, these algorithms dynamically analyze the video signal in real time. For darker scenes, the backlight may be slightly dimmed to enhance black levels and detail in shadowed areas. For bright scenes, it boosts the backlight while simultaneously adjusting the color processing to maintain accurate hues. This dynamic optimization, found in models like the MS321PC – 32" 4K Surgical Monitor, ensures the surgeon sees a consistently clear, high-contrast, and color-accurate image of the surgical field, regardless of the challenging lighting conditions.

Conclusion

Backlight correction is a system of technologies. It works to ensure the stable, uniform, and accurate luminance that is absolutely essential for reliable and confident medical imaging.

📧 Want to integrate displays with advanced backlight correction into your workflow? Contact Martin at martin@reshinmonitors.com to learn more about Reshin’s solutions.

-

Understanding LED backlights is crucial for grasping their role in display technology, especially in medical applications. ↩

-

Exploring visual reliability will highlight its significance in diagnostics and patient safety in medical imaging. ↩

-

Exploring uniformity correction technology reveals how it enhances image accuracy, vital for diagnostics. ↩

-

Understanding performance drift is crucial for maintaining display accuracy, especially in medical settings. ↩

-

Exploring continuous feedback loops can enhance your knowledge of display technology and its importance in precision. ↩

-

Understanding this system is crucial for maintaining display performance and ensuring accurate diagnostics in medical settings. ↩

-

Exploring this concept helps hospitals make informed decisions about their investments and long-term budgeting. ↩

-

Understanding GSDF is crucial for ensuring accurate medical image rendering, making this resource invaluable for professionals in the field. ↩

-

Exploring calibration software options can enhance the accuracy of medical displays, ensuring compliance with industry standards. ↩

-

Explore this link to discover top surgical monitors that enhance visibility and precision in operating rooms. ↩

-

Learn how backlight control algorithms optimize display quality for better visibility in various lighting conditions. ↩