Medical imaging equipment manufacturers frequently face costly warranty claims, support calls, and on-site visits for issues that aren’t actually caused by their core technology. Could these expensive service problems actually originate from unstable display components that undermine your entire system’s performance?

High-stability medical-grade monitors help imaging device manufacturers reduce after-sales risks by minimizing brightness drift, color variation, early panel decay, and cross-site performance differences. From my OEM engineering experience, models such as MS270P, MS322PB, and MS430PC deliver predictable long-term performance and significantly reduce support burden.

As an engineering specialist supporting OEM imaging device manufacturers, I’ve consistently observed that display instability1 becomes a hidden driver of after-sales cost. End-users often misattribute any visual inconsistency to the imaging device itself, which leads to unnecessary troubleshooting and misplaced warranty claims. When this misattribution happens across multiple facilities, it amplifies operational risk and erodes customer trust.

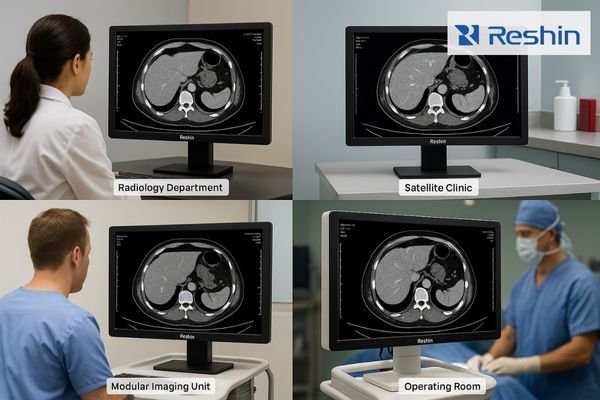

For heads of product, service directors, and OEM business leaders, display-related risk management is essential. High-stability monitors directly increase system reliability by addressing luminance consistency, color stability, signal integrity, and mechanical durability, ensuring the imaging device is evaluated based on its true performance.

What Display Failure Modes Cause the Most After-Sales Issues?

Imaging device manufacturers frequently discover that a significant portion of their support calls originate from visual quality complaints rather than actual device functionality issues. What specific display failure modes are silently driving up warranty costs and eroding customer satisfaction?

Most costly after-sales issues arise from subtle display degradations that end-users cannot easily diagnose—such as luminance decay, uniformity loss, color drift, and intermittent signal issues. These problems are often interpreted as device failures, creating hidden risk for OEM manufacturers and increasing warranty claims and support workload.

Understanding these patterns allows manufacturers to prioritize the display elements most strongly linked to after-sales risk. Display degradation develops gradually, making it difficult for end-users to recognize root causes. Small shifts in brightness or uniformity quickly influence clinical perception, leading users to believe the imaging device is underperforming. Over time, these recurring concerns create widespread dissatisfaction and repeated service calls.

By proactively addressing known failure points—panel aging, non-uniform backlights, grayscale drift, and signal artifacts—manufacturers can avoid unnecessary troubleshooting cycles. Strengthening display reliability2 at the component level improves clinical experience, reduces field complaints, and ultimately protects the brand reputation of the entire imaging system.

Primary Display Failure Patterns and Their After-Sales Business Impact

The most problematic display failures in medical imaging environments develop gradually and often escape proper end-user diagnosis:

| Display Failure Mode | Typical End-User Complaint | Actual Root Cause | Business Impact |

|---|---|---|---|

| Luminance Decay | "Images appear darker than before" | Backlight degradation without stabilization | A major portion of image-quality complaints |

| Non-Uniform Brightness | "Center looks different from edges" | Panel aging inconsistency | Requires costly on-site diagnosis |

| Color/Grayscale Drift | "Images don’t match previous installs" | Aging without calibration | Creates perception of device inconsistency |

| Intermittent Signal Artifacts | "Screen flickers or blanks" | Consumer-grade interfaces | High troubleshooting burden |

| Mechanical Degradation | "Monitor feels worn/damaged" | Non-medical construction | Damages brand perception |

How Does High Luminance Stability Reduce Warranty Claims and After-Sales Risk?

Many imaging OEMs find that “dark image” complaints represent a major share of service calls within the first 12–18 months. How significant is backlight stability in reducing these costly support incidents?

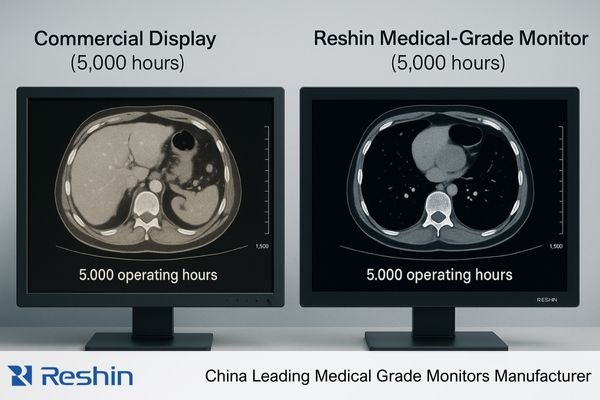

Luminance stability has one of the strongest impacts on long-term after-sales performance. In many of my OEM deployments, conventional displays experienced rapid brightness loss, triggering “dark image” or “detail loss” complaints. Medical-grade monitors with CBS or closed-loop stabilization maintain consistent luminance and prevent most brightness-related service events.

Brightness decay affects far more than visual comfort—it impacts diagnostic confidence and user perception of device quality. When luminance drops, subtle structures appear harder to differentiate, and clinicians often believe the imaging device is underperforming. This leads to repeated troubleshooting sessions that consume engineering resources, even though the device itself is not at fault.

High-stability medical-grade monitors3 actively monitor backlight behavior and compensate for aging, keeping luminance output within controlled ranges. Maintaining predictable brightness levels reduces recalibration needs, ensures long-term DICOM behavior, and stabilizes visual expectations across installations. For OEMs, this directly translates into fewer support tickets, fewer on-site visits, and higher customer satisfaction during multi-year deployments.

Using stabilized displays helps OEMs reduce brightness-related complaints, maintain DICOM consistency longer, and deliver a more predictable clinical experience across all installations.

Why Do Color Consistency and Calibration Reduce Cross-Site Support Costs?

Multi-site healthcare networks frequently report that identical imaging systems “look different” across locations. Could color inconsistency in displays be creating phantom device performance issues?

Color variation between sites becomes one of the most common hidden sources of after-sales burden. I’ve supported OEM deployments across dozens of facilities where aging differences between displays created mismatched image tones, leading users to assume the imaging device was inconsistent. Factory calibration and drift control eliminate these discrepancies.

Color drift is especially problematic in enterprise networks where clinicians frequently compare systems. Even minor variations in grayscale, gamma, or color temperature can cause doubt about device reliability. When multiple installations present different visual characteristics, users lose confidence in system standardization, accelerating support escalations.

High-stability medical-grade displays address this challenge through uniformity correction, panel characterization, consistent component binning, and long-term drift management. These features ensure that every unit performs within tightly controlled visual tolerances. Standardized output across facilities reduces calibration visits, prevents unnecessary device-side troubleshooting, and helps OEMs maintain consistent imaging performance across their largest customer accounts.

How Do Better Signal Interfaces Reduce Integration Risks?

Integration teams often encounter unstable display performance during installation or after delivery. How do medical-grade interfaces eliminate these costly troubleshooting cycles?

Intermittent blanking, flicker, and signal-drop complaints often originate from consumer-grade HDMI ports or poorly shielded connectors. In my integration projects, medical-grade monitors with SDI, locking HDMI, and enhanced EMI resistance eliminated nearly all signal-stability complaints and reduced troubleshooting time dramatically.

Signal reliability profoundly impacts perceived device quality. Even when the imaging system works flawlessly, a momentary signal drop can invalidate the entire end-user experience. In ORs, endoscopy towers, or mobile carts—where cables flex frequently and electromagnetic interference is common—consumer ports fail prematurely or lose connection intermittently.

Medical-grade interfaces address these issues through improved shielding, dedicated grounding, medical-specific signaling protocols, and locking connectors. These enhancements maintain signal integrity4, reduce installation complexity, and prevent accidental disconnections. For OEMs, stable connectivity ensures that system performance is judged accurately, not undermined by external interface issues.

Reliable input handling preserves signal integrity, supports longer cable runs, and reduces the likelihood of repeat support calls attributed to image interruptions.

How Can Medical-Grade Mechanical Design Reduce Field Failures?

Medical environments place displays under stresses that commercial monitors are not built to withstand. How important is medical-grade mechanical design in preventing warranty claims?

Mechanical reliability plays a far greater role in warranty cost than many OEMs expect. In my fieldwork, commercial displays frequently suffered bezel cracks, fluid ingress, loose mounts, and dust buildup. Medical-grade enclosures with reinforced glass, sealed surfaces, and rigid mounting systems significantly reduce these failures.

Physical durability determines how displays perform over years of daily use, especially in surgical and mobile environments. Repeated cleaning cycles, exposure to disinfectants, accidental impacts, and constant repositioning place heavy demands on enclosure integrity. Commercial monitors lack the structural reinforcement, sealant properties, and mechanical precision required for these environments.

Medical-grade designs incorporate sealed front surfaces, impact-resistant materials, thermal optimization, cable-strain protection, and reinforced VESA mounts. These features reduce physical-damage claims, minimize safety risks, and extend display lifespan. For OEMs, the long-term benefit is reduced field failures, fewer replacement costs, and strengthened customer confidence in product durability.

How Do High-Stability Monitors Improve OEM Delivery Predictability and Support Planning?

Manufacturers often face batch variations where displays of the same model present different visual characteristics. How do high-stability medical monitors improve delivery predictability?

Component variance creates major operational uncertainty for OEMs. I’ve seen multiple deployments delayed due to visible differences between supposedly identical panels. High-stability medical monitors use strict component binning, uniformity correction, and extended QA testing to ensure consistent unit-to-unit performance.

Consistency is crucial for OEM manufacturing workflows5. When different batches of displays exhibit different brightness levels, color temperatures, or uniformity characteristics, integration teams must spend additional time validating each delivery. This slows production, increases testing costs, and creates uncertainty for large deployment schedules.

Medical-grade displays undergo tighter manufacturing control, including individual panel measurement, performance matching, burn-in testing, and traceable calibration records. These controls reduce integration rejections, simplify inventory planning, and improve predictability for system builders who rely on consistent behavior across units. As a result, support variance decreases, long-term reliability improves, and institutional customers gain confidence in OEM quality standards.

Better unit-to-unit consistency minimizes integration time, reduces support variability, and supports smoother OEM production planning.

Which Monitor Models Are Best for Reducing After-Sales Risk?

With numerous displays claiming medical-grade status, which models actually reduce after-sales burden in real deployments?

Based on my OEM engineering experience, Reshin models such as the MS270P, MS322PB, and MS430PC deliver exceptional stability across surgical, imaging, and endoscopy applications. Their luminance stabilization, uniformity correction, locking interfaces, and reinforced design directly address failure modes that drive after-sales cost.

These models include luminance stabilization, uniformity correction, medical-grade connectivity, and reinforced mechanical design—directly addressing the most common after-sales risks encountered in OEM deployments.

| Model | Specifications | Key Stability Features | Best For Reducing |

|---|---|---|---|

| MS270P | 27" FHD Surgical Monitor | Backlight stabilization, sealed bezel, 10-bit processing | Color inconsistency, early darkening |

| MS322PB | 32" 4K Surgical Monitor | SDI/HDMI with locking connectors, uniformity correction | Signal interruptions, multi-site variation |

| MS430PC | 43" 4K Surgical Monitor | Reinforced chassis, optical bonding, wide temperature tolerance | Physical failures, glare complaints |

Conclusion

Display stability is one of the most underappreciated factors influencing the total after-sales cost of medical imaging systems. Throughout this article, we examined how luminance decay, uniformity variation, color drift, signal instability, and mechanical failures drive warranty claims and customer dissatisfaction. High-stability medical-grade displays address these issues directly, providing OEMs with improved reliability, fewer service events, and stronger perceived product quality.

Strengthening display stability directly reduces after-sales risk and enhances system performance across deployments. If your OEM team is planning an upgrade or evaluating new displays, our engineering group can assist with selection and technical assessment. Contact us here:

📧 info@reshinmonitors.com

🌐 https://reshinmonitors.com/

-

Understanding display instability can help manufacturers reduce after-sales costs and improve customer satisfaction. ↩

-

Exploring ways to enhance display reliability can lead to better performance and customer trust in imaging devices. ↩

-

Exploring high-stability monitors can reveal how they enhance imaging quality and reduce support issues in clinical settings. ↩

-

Understanding signal integrity is crucial for ensuring high-quality performance in medical devices, enhancing user experience. ↩

-

Exploring this resource will provide insights into optimizing OEM processes for better efficiency and quality. ↩