Medical displays are exposed to liquids and dust daily. This constant exposure can lead to equipment failure at critical moments. Ingress Protection (IP) ratings provide assurance against these environmental hazards.

This article explores the top five IP (Ingress Protection) ratings relevant to medical displays. I will detail the specific protections offered by IPX1, IPX4, IP5X, IP6X, and IP65, explaining their importance in various clinical environments from general wards to sterile operating rooms.

Ingress Protection ratings1 are not just technical specifications; they are a fundamental measure of a medical display’s reliability and safety in a clinical setting. Defined by the international standard IEC 605292, an IP rating clarifies the level of sealing effectiveness against intrusion from foreign bodies (like dust and dirt) and moisture. The rating consists of two digits. The first digit (0-6) indicates protection against solids, while the second digit (0-9) indicates protection against liquids. An "X" in place of a digit means the enclosure is not rated for that category. In a hospital, failure to select a display with an appropriate IP rating can have serious consequences. A routine cleaning with a disinfectant wipe could introduce fluid into an unsealed enclosure, causing an electrical short. Airborne dust in a busy environment could accumulate inside a monitor, leading to overheating and premature component failure. For equipment like the MS270P surgical display, which is used in environments where fluid exposure is routine, having a certified IP rating is a non-negotiable requirement for ensuring device longevity, performance reliability, and compliance with stringent hospital hygiene protocols.

Understanding IP Rating Digits

| Digit | First Digit (Solids Protection) | Second Digit (Liquids Protection) |

|---|---|---|

| 0 | No protection. | No protection. |

| 1 | Protected against objects >50mm. | Protected against vertically dripping water. |

| 2 | Protected against objects >12.5mm. | Protected against water dripping at a 15° angle. |

| 3 | Protected against objects >2.5mm. | Protected against spraying water. |

| 4 | Protected against objects >1mm. | Protected against splashing water from any direction. |

| 5 | Dust-protected (limited ingress). | Protected against low-pressure water jets. |

| 6 | Dust-tight (no ingress). | Protected against powerful water jets. |

1. IPX1 protects against vertically dripping water exposure

Condensation or minor drips seem harmless. But for sensitive electronics, even a small amount of vertical dripping water can cause damage. An IPX1 rating provides essential baseline protection against this risk.

IPX1 certification ensures that a display’s enclosure can withstand vertically dripping water for at least 10 minutes. This rating is suitable for controlled environments where direct water exposure is minimal but condensation or drips are a possibility.

The IPX1 rating is the first level of protection against water ingress3. While it may seem minimal, it is a crucial specification for equipment used in environments with controlled climates where condensation can occur. The testing procedure involves placing the device in its normal operating position and subjecting it to the equivalent of 1 mm of rainfall per minute for ten minutes. This simulates scenarios like drips from overhead pipes, condensation forming on a cool surface in a humid room, or incidental drips during nearby procedures. An unrated device could easily fail under these conditions as water finds its way through seams and ventilation holes to the internal electronics. An entry-level monitor like the MS192SA, while not intended for fluid-intensive surgical environments, benefits from an IPX1 rating4 to ensure its reliability in general clinical areas. This level of protection provides a necessary safeguard against the most common and basic form of liquid exposure, preventing unexpected failures and extending the operational life of the equipment in standard hospital wards or consultation rooms.

2. IPX4 shields displays from splashing water from any direction

Cleaning protocols and accidental splashes are common in hospitals. Unprotected displays are vulnerable to damage from these multidirectional fluids. IPX4 provides robust protection against this everyday clinical reality.

An IPX4 rating signifies that the display is protected against splashing water from all directions. This is a common requirement for devices used near sinks or in areas that undergo spray cleaning and disinfection protocols.

The jump to an IPX4 rating5 represents a significant increase in liquid protection, making it suitable for a much wider range of clinical applications. The IPX4 test involves subjecting the enclosure to a powerful oscillating spray of water from all directions for at least five minutes. This simulates the conditions of a thorough spray cleaning or an accidental splash of bodily fluids or irrigation solutions during a medical procedure. In environments like emergency rooms, intensive care units, and many operating rooms, this level of protection is often considered the minimum standard. The ability to withstand splashing water ensures that the device can be cleaned effectively without risk of internal damage, supporting vital infection control protocols. an IPX4 rating is essential. It provides the confidence that the monitor can perform reliably even when positioned close to the surgical field where fluid splashes are a constant and expected occurrence. This ruggedness is key to maintaining operational uptime in dynamic and demanding medical settings.

3. IP5X provides dust protection for operating room environments

Airborne dust and other particulates are present in all environments. These particles can infiltrate electronics, causing overheating and failure. IP5X provides a crucial barrier against this invisible threat.

An IP5X rating indicates that the enclosure is "dust-protected." While not completely sealed against all dust, it prevents enough dust from entering to interfere with the safe and satisfactory operation of the internal components.

An IP5X rating6 addresses the first digit of the IP code, focusing on protection against solid particles. To achieve this rating, a device’s enclosure must prevent the ingress of enough dust to cause malfunction. The test involves placing the device in a dust chamber containing fine talcum powder and running it for up to eight hours to ensure that no harmful deposits accumulate inside. This level of protection is critical in environments where air quality is important but not necessarily sterile, such as general operating rooms, procedure rooms, and busy diagnostic labs. The accumulation of dust on internal electronic components can act as an insulator, trapping heat and leading to overheating, performance degradation, and eventual failure. Furthermore, dust can interfere with moving parts like cooling fans. By ensuring a dust-protected design7, as seen in a diagnostic monitor like the MS321PB, the device’s longevity and reliability are significantly enhanced. It guarantees consistent performance over many years, free from the gradual decline caused by internal contamination.

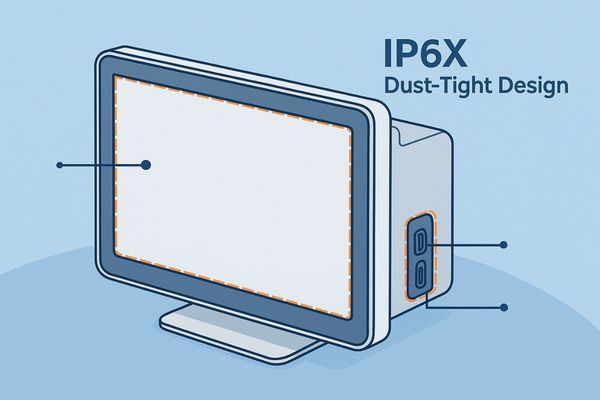

4. IP6X ensures complete dust-tight sealing for sterile conditions

In sterile fields and cleanrooms, any particle contamination is unacceptable. Standard electronics are not built for these environments. A fully sealed, dust-tight enclosure is the only viable solution.

IP6X is the highest level of protection against solid ingress. It signifies that the enclosure is completely "dust-tight," meaning no dust can enter the device under any test condition, making it ideal for sterile environments.

The IP6X rating represents the pinnacle of protection against solid particles. The "6" indicates that the enclosure is completely sealed against dust ingress, offering a total barrier. The certification test is rigorous, subjecting the device to a vacuum within its enclosure while it is surrounded by agitated talcum powder. The vacuum attempts to pull dust in through any potential opening; a successful test confirms that no dust whatsoever has penetrated the seal after an eight-hour period. This level of protection is essential for equipment intended for use in sterile environments8, pharmaceutical cleanrooms, or specialized surgical suites where particle contamination could compromise patient safety or research integrity. A fully sealed design also eliminates the need for cooling fans, which can harbor and circulate contaminants. A dual-screen diagnostic monitor such as the MD46C, if designed for such a demanding environment, would require an IP6X rating9 to guarantee that it does not introduce any foreign particulates, thereby upholding the strict hygiene and sterility standards of its intended application.

5. IP65 combines strong dust and low-pressure water resistance

Harsh clinical environments demand protection from both dust and liquids. A device must withstand both cleaning jets and airborne particles. A combined rating like IP65 provides this comprehensive defense.

The IP65 rating signifies a device that is both completely dust-tight (IP6X) and protected against low-pressure water jets from any direction (IPX5). This makes it highly resilient and suitable for frequent, intensive cleaning protocols.

An IP65 rating provides a powerful combination of protection that makes a display exceptionally versatile and durable for demanding medical environments. The first digit, "6," guarantees that the enclosure is completely dust-tight, ensuring no solid particles can compromise the internal electronics. The second digit, "5," certifies that the enclosure can withstand being sprayed by low-pressure water jets from any angle without harmful effects. The IPX5 test involves using a nozzle to spray water at the device for at least three minutes, a much more rigorous trial than the splashing test for IPX4. This dual protection makes an IP65-rated monitor an excellent choice for operating rooms, emergency departments, and other areas where devices must endure both airborne particulates and frequent, thorough wash-downs with cleaning and disinfecting solutions. an IP65 rating10 is a mark of superior engineering. It assures the clinical team that the display is built to withstand the realities of a harsh surgical environment, delivering unwavering performance day after day.

Summary of Featured IP Ratings

| IP Rating | Solids Protection | Liquids Protection | Typical Use Case |

|---|---|---|---|

| IPX1 | Not Rated | Vertically Dripping Water | Controlled environment, condensation risk. |

| IPX4 | Not Rated | Splashing Water | General clinical areas, near sinks. |

| IP5X | Dust-Protected | Not Rated | Environments with airborne particulates. |

| IP6X | Dust-Tight | Not Rated | Sterile fields, cleanrooms. |

| IP65 | Dust-Tight | Low-Pressure Water Jets | Operating rooms, frequent wash-downs. |

Conclusion

Selecting a medical display with the correct IP rating is crucial for ensuring device reliability, safety, and compliance with hospital infection control and hygiene standards.

📧 Need help choosing IP-rated displays that meet strict hospital hygiene requirements? Contact Martin at martin@reshinmonitors.com

- Understanding Ingress Protection ratings is crucial for ensuring the reliability and safety of medical displays in clinical settings. ↩

- Exploring IEC 60529 will provide insights into the standards that ensure medical equipment is safe and reliable. ↩

- Exploring the impact of water ingress can help you protect your devices and enhance their longevity. ↩

- Understanding the IPX1 rating is essential for ensuring equipment reliability in environments prone to moisture. ↩

- Understanding the IPX4 rating is crucial for ensuring the safety and reliability of medical devices in fluid-prone environments. ↩

- Understanding the IP5X rating is crucial for ensuring device longevity and reliability in various environments. ↩

- Exploring dust-protected designs can reveal how they prevent overheating and ensure consistent performance in critical settings. ↩

- Exploring sterile environments reveals best practices for maintaining cleanliness, essential for safety in healthcare and research. ↩

- Understanding the IP6X rating is crucial for ensuring equipment meets hygiene standards in sensitive environments. ↩

- Understanding the IP65 rating is crucial for ensuring the durability and reliability of medical devices in challenging environments. ↩