In my experience working with surgical display development teams, company-wide events like our annual gala provide a rare chance to align technical direction with manufacturing reality—without losing sight of what the OR actually needs.

Reshin’s 2026 annual gala in Shenzhen brought colleagues across functions together to reinforce manufacturing-first priorities for surgical display development. The event emphasized quality gates, traceability, and OR-readiness as system outcomes, showing how medical-grade reliability depends on repeatable delivery, disciplined change control, verification routines, and steady cross-team collaboration from design through field deployment.

From my work with surgical visualization systems, the most valuable outcome of our January 24, 2026 gathering was the shared clarity it created: a manufacturing-first mindset is not a slogan, but a daily decision framework. It shapes how we prioritize stability over shortcuts, how we coordinate under delivery pressure, and how we keep surgical display development grounded in long-run reliability, verification discipline, and usability in demanding OR workflows.

A company-wide annual gala in Shenzhen that set our direction for 2026

Our annual company gathering provided essential alignment between technical development and manufacturing execution priorities.

On January 24, 2026, Reshin held its company-wide annual gala in Shenzhen, bringing colleagues across functions together to reflect on the past year and align on what comes next for surgical display development and manufacturing excellence. From my technical vantage point, the most valuable outcome was the shared clarity it created around how a manufacturing-first mindset shows up in daily decisions, team coordination under real delivery pressure, and sustained focus on OR-ready reliability.

In my OR integration work at Reshin, I’ve learned that successful surgical display development is rarely “owned” by a single team. It is built through clean interfaces between design, manufacturing, quality, and field feedback—so that what we promise on paper can be produced consistently, verified clearly, and supported reliably after deployment.

Cross-Functional Alignment and Communication

The gala created a shared working context between engineering, manufacturing, quality assurance, and field support. Instead of treating decisions as isolated technical debates, we revisited how choices ripple across feasibility, inspection points, acceptance readiness, and long-term stability in clinical environments.

Strategic Direction for Manufacturing Excellence

Company-wide alignment also helps technical teams translate priorities into executable actions: clearer criteria for what “done” means, earlier verification checkpoints, and fewer assumptions during handoffs. That is the practical foundation for building surgical displays that can keep performing through long operating hours and varied OR setups.

One factory-floor mindset: quality gates, traceability, and readiness for the OR

The event emphasized manufacturing discipline as the foundation for surgical display reliability and clinical acceptance.

What stood out across the event was a shared manufacturer’s mindset that keeps discussions close to what can be executed on the factory floor and proven in the field. For surgical displays, that mindset translates into controllable quality gates, disciplined change management, and traceability that supports verification and acceptance, ensuring that OR-ready status is not a claim but a reproducible result sustained through product lifecycles.

This factory-floor perspective keeps development teams focused on deliverable outcomes rather than theoretical improvements. When we discuss a new feature or a performance target, the conversation quickly expands to include how it will be built, how it will be checked, and how it will be supported. That is how innovation stays compatible with repeatability.

Manufacturing-first thinking also helps teams avoid a common trap: treating reliability as an afterthought to be “tested in” later. In OR settings, downtime and inconsistency are not minor inconveniences—they create unacceptable risk and operational disruption. The discipline is to design and verify with real installation and maintenance constraints in mind from the start.

General Manager Chen Ping’s training on our journey—and the engineering discipline behind it

Leadership training connected company development history to the systematic discipline required for medical device manufacturing success.

General Manager Chen Ping’s training on Reshin’s development history connected company milestones to the discipline required to sustain them through building key capabilities in-house, treating validation and documentation as first-class deliverables, and making OR-ready status a system outcome rather than a single metric.

When I look back at successful OR deployments, a consistent pattern appears: long-term stability is usually the result of small choices made early—choices that are easy to overlook when schedules tighten. The training reinforced the idea that capability building is not only about what we can design, but what we can repeatedly prove, record, and support at scale.

| Development Milestone | Engineering Discipline | Manufacturing Impact | OR Integration Benefit | Sustainability Factor |

|---|---|---|---|---|

| In-House Capabilities | Controlled design validation | Predictable quality outcomes | Consistent field performance | Reduced external dependencies |

| Documentation Standards | Comprehensive verification records | Traceable manufacturing processes | Simplified acceptance procedures | Regulatory compliance support |

| System-Level Thinking | Integrated reliability approach | Coordinated quality gates | Dependable OR deployment | Long-term serviceability |

| Field Validation Focus | Real-world testing protocols | Production-representative samples | Validated clinical compatibility | Continuous improvement loops |

| Cross-Team Coordination | Shared quality objectives | Aligned manufacturing priorities | Unified field support | Sustainable team development |

For those of us closer to product and manufacturing processes, the message was practical: credibility is earned through repeatable delivery and the willingness to verify, document, and improve consistently. In medical-grade displays, that consistency is what allows performance to remain predictable through long procedures and varied OR conditions.

Recognition and celebration that strengthened team cohesion

Award recognition and celebration activities reinforced the collaborative culture essential for manufacturing excellence.

The gala set aside time to recognize standout contributions, followed by lighter lucky-draw celebrations that kept the atmosphere warm and inclusive. From a technical team viewpoint, that combination matters because stable manufacturing outcomes rely on people who maintain standards, catch issues early, and cooperate across boundaries.

From an engineering standpoint, recognizing individual and team contributions does more than boost morale—it protects the habits that make quality repeatable. Standards are kept because people care, and because teams trust each other enough to raise concerns early rather than hiding them until they become urgent.

Individual Excellence Recognition

Recognition programs highlight the kind of work that strengthens delivery: consistent attention to quality gates, careful problem-solving under constraints, and coordination that prevents small deviations from turning into field issues later.

Team Building and Inclusive Culture

Celebration activities create shared experiences that tighten working relationships across engineering, manufacturing, and support functions. Those relationships matter most when schedules compress or unexpected issues surface—because fast, calm collaboration is often the difference between a contained adjustment and a disruptive rework.

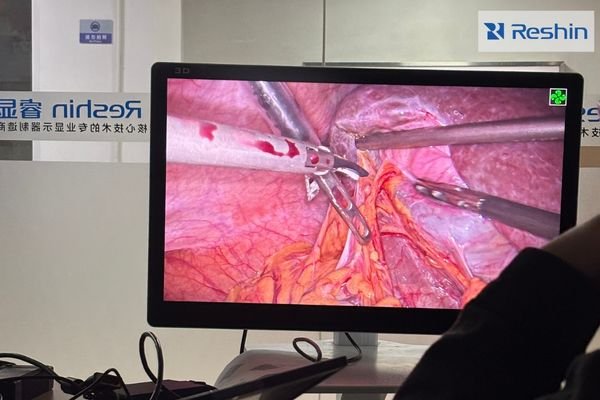

Two 31.5-inch surgical display launches that point to the next step

New product launches demonstrate our commitment to advanced surgical visualization while maintaining manufacturing discipline.

From a manufacturer’s perspective, new products are best explained through real OR workflows and deliverability where 31.5-inch class displays support readability at typical viewing distances and fit multi-source scenarios requiring stable 4K signal handling and predictable color and brightness behavior over long operating hours.

This year’s direction includes surgical displays designed for depth-sensitive procedures and enhanced contrast applications while maintaining the same adoption essentials including mounting practicality, cleaning compatibility, acceptance validation, and serviceability across years of clinical use.

| Clinical Role / Application | Usage Pattern | Display Requirements | Recommended Model | Key Integration Considerations |

|---|---|---|---|---|

| 3D Surgical Applications | Depth-sensitive procedures | Advanced 3D processing, stable stereoscopic display | MS324PA | Specialized mounting, validated 3D compatibility |

| High-Contrast Visualization | Detail-intensive surgical work | Mini-LED backlighting, enhanced contrast control | MS323PA | Image calibration workflow, integration checks |

The technical approach emphasizes practical integration within existing routing and redundancy systems while supporting stronger visualization capability. Just as importantly, the manufacturing-first lens keeps the focus on consistency—so that image quality behavior, calibration expectations, and service routines remain predictable across deployments rather than varying case by case.

Both launches reflect the same underlying philosophy: advanced features matter, but they only create value when they can be produced consistently, verified systematically, and supported smoothly in real OR environments.

What I took back to work: tighter loops, clearer handoffs, better outcomes

Personal reflections on practical improvements for daily engineering and manufacturing coordination.

After the gala, what stayed with me was a very practical checklist for day-to-day execution including keeping feedback loops tight between design, production, and quality teams, making handoffs clearer with fewer assumptions and more verifiable criteria, and treating every field observation as a chance to harden the next build cycle.

That kind of quiet improvement is what manufacturing-first teams rely on. It reduces surprises during acceptance, lowers the cost of late-stage changes, and makes performance more predictable across different OR installations. Over time, those small improvements compound into smoother delivery and fewer disruptions for clinical teams.

Practical implementation means fewer “implicit” agreements and more checkable criteria: clearer design-to-manufacturing handoffs, earlier validation checkpoints during development cycles, and systematic capture of field feedback. When these loops stay tight, the next build benefits immediately—not only in lab results, but in real deployment stability.

Conclusion

Walking away from the Shenzhen annual gala, I felt renewed confidence in a simple approach that keeps promises grounded in what we can repeatedly deliver through manufacturing discipline and systematic quality verification. In surgical displays, that means treating reliability as a system property achieved through coordinated team effort, treating verification as a standard habit rather than an occasional requirement, and maintaining real, frequent cross-team collaboration that ensures the next year builds on quieter, more dependable outcomes that customers can trust. The event reinforced that successful medical device development requires balancing innovation ambitions with manufacturing realities, ensuring that every technical advancement can be produced consistently and validated thoroughly before deployment in clinical environments where performance and reliability directly impact surgical outcomes.

Our commitment at Reshin emphasizes that annual alignment events like this gala serve not just as celebration opportunities but as essential coordination mechanisms that keep technical teams focused on deliverable improvements rather than theoretical advances, ensuring that surgical display development maintains the systematic discipline necessary for medical device manufacturing excellence. When company-wide alignment combines recognition of individual contributions with clear strategic direction and practical execution focus, the result is stronger team cohesion and more reliable delivery of surgical displays that meet the demanding requirements of modern OR environments throughout their operational lifecycles.

✉️ info@reshinmonitors.com

🌐 https://reshinmonitors.com/