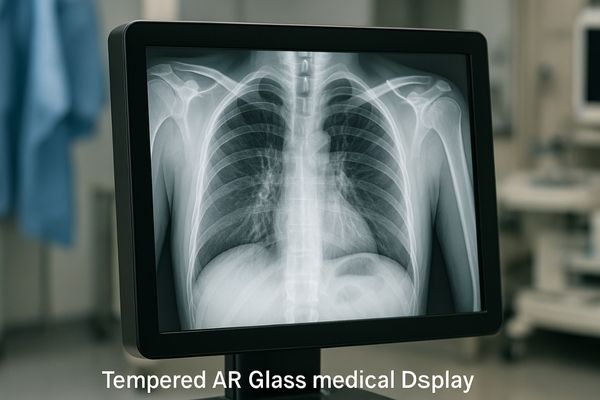

Struggling with screen glare during critical procedures? Poor visibility can compromise focus. Medical displays need optimal clarity, and tempered anti-reflective glass provides a crucial solution.

Tempered anti-reflective (AR) glass significantly enhances medical display performance by minimizing glare, improving image contrast, and increasing durability. This specialized glass ensures clearer visuals for accurate diagnosis and safer surgical interventions, while also supporting infection control.

The screen you look at in a clinical setting is more than just a piece of glass. It is a critical component that can impact patient outcomes. We will explore how tempered anti-reflective glass meets the demanding requirements of modern healthcare. Understanding this technology helps appreciate its value in surgical and diagnostic environments.

Why is anti-reflective glass essential in surgical and diagnostic displays?

Are reflections obscuring vital details on your medical screen? This common issue can lead to misinterpretations. Anti-reflective glass addresses this problem directly, enhancing visibility for better patient care.

Anti-reflective glass is essential because it drastically reduces glare from ambient and surgical lights. This improves image contrast and readability, allowing medical professionals to see critical anatomical details clearly and make accurate assessments.

I find that the quality of visual information is paramount in any medical procedure. Anti-reflective (AR) glass1 plays a key role here. It works by using thin-film optical coatings that cause destructive interference for reflected light waves. This significantly reduces the amount of light that bounces off the screen surface. In brightly lit environments, such as operating rooms with intense surgical lights, or diagnostic rooms with various light sources, this reduction in glare is not just a convenience; it is a necessity. Surgeons can maintain focus on the surgical site displayed on the monitor without being distracted or hindered by reflections. Similarly, radiologists interpreting complex scans benefit from the enhanced clarity, as subtle grayscale variations become more discernible. This improvement in contrast and detail perception directly contributes to diagnostic accuracy2 and confidence. The ability to see true-to-life colors and precise details, especially in minimally invasive surgery3 or when reviewing PACS images, cannot be overstated.

The Science Behind Glare Reduction

AR coatings typically consist of multiple layers of dielectric materials. Each layer has a specific thickness and refractive index.

- Destructive Interference: When light hits the coated surface, some reflects off the top of the coating, and some reflects off the underlying glass. The coating thickness is designed so these reflected waves are out of phase, cancelling each other out.

- Increased Transmission: By reducing reflection, more light from the display passes through to the viewer, resulting in a brighter, clearer image.

Impact on Different Medical Fields

The benefits of AR glass extend across various medical applications.

| Medical Field | Benefit of AR Glass | Example Scenario |

|---|---|---|

| Surgery (Endoscopy) | Clearer view of internal structures, reduced eye strain | Laparoscopic surgery with overhead OR lights |

| Radiology (PACS) | Improved grayscale differentiation, accurate diagnosis | Reading mammograms or CT scans in a review room |

| Dentistry | Better visibility of intraoral images, precise work | Viewing X-rays or intraoral camera feeds chairside |

| Ophthalmology | Enhanced detail in retinal scans, accurate assessment | Analyzing Optical Coherence Tomography (OCT) images |

Medical professionals rely on what they see. AR glass ensures they see the most accurate and unobstructed image possible. This directly supports better clinical decision-making.

How does tempered glass enhance safety and durability in clinical settings?

Worried about accidental impacts damaging your expensive medical displays? Breakage can disrupt procedures and pose safety risks. Tempered glass offers a robust solution for demanding clinical environments.

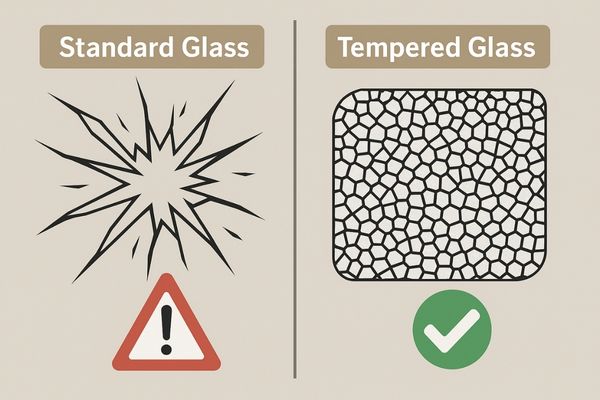

Tempered glass enhances safety by being four to five times stronger than standard glass. If it breaks, it shatters into small, dull-edged pieces, reducing injury risk. Its durability minimizes replacements and operational downtime.

I believe the physical resilience of medical equipment is as important as its technical performance. Tempered glass significantly contributes to this resilience. The tempering process involves heating glass to high temperatures and then rapidly cooling its surface. This creates a state of high compression on the surface and tension in the interior. This internal stress distribution is what gives tempered glass its remarkable strength. It can withstand much greater impacts, pressures, and thermal stresses than ordinary, or annealed, glass. In a busy hospital environment, equipment is often moved, bumped by carts, or subject to accidental contact. A display protected by tempered glass is far less likely to crack or shatter from such incidents. This durability translates to a longer lifespan for the display, reducing the total cost of ownership. Fewer breakages also mean less disruption to clinical workflows. Imagine the consequences of a critical display failing during a complex surgical procedure. Tempered glass provides an essential layer of protection against such events, ensuring operational continuity.

The Tempering Process and Its Effects

Understanding how tempered glass4 is made helps appreciate its properties.

- Thermal Tempering: Glass is heated to approximately 620°C (1148°F) and then rapidly cooled with air jets. The surface cools and contracts faster than the interior.

- Chemical Tempering: Glass is submerged in a molten potassium salt bath. Larger potassium ions exchange with smaller sodium ions in the glass surface, creating compressive stress.

Key Durability Advantages

Tempered glass offers several advantages that contribute to its longevity in clinical use.

- Impact Resistance: It can withstand significant force without breaking. This protects the delicate underlying LCD panel.

- Scratch Resistance: While not scratch-proof, tempered glass is more resistant to surface scratches from routine cleaning or accidental contact with instruments than many plastic screen protectors. This helps maintain optical clarity over time.

- Thermal Shock Resistance: It can endure rapid temperature changes without shattering, which can be relevant in environments with fluctuating temperatures or during certain cleaning processes.

This enhanced toughness makes tempered glass an ideal choice for devices that face constant use and potential physical stress.

How does tempered glass enhance safety and durability in clinical settings?

Is equipment safety a top priority in your medical facility? Beyond just resisting impacts, tempered glass offers specific safety advantages. Its unique properties protect both patients and staff.

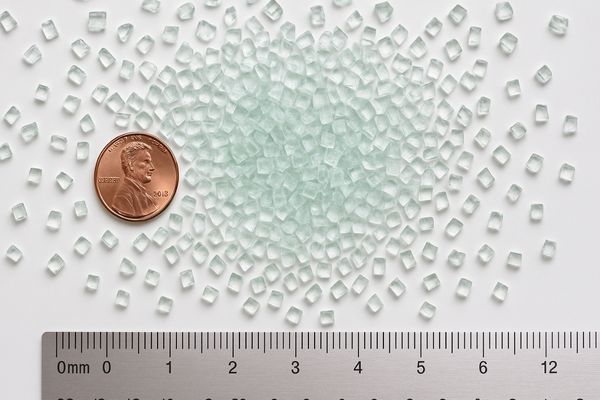

Tempered glass enhances safety because, upon breaking, it fragments into small, granular, and relatively harmless pieces instead of sharp, jagged shards. This significantly reduces the risk of cuts and injuries in clinical environments.

I always emphasize that equipment design must prioritize user and patient safety5. Tempered glass is a prime example of a material engineered with safety in mind. The primary safety benefit comes from its characteristic fracture pattern6. Unlike annealed glass, which breaks into dangerous, sharp shards, tempered glass7 crumbles into small, pebble-like pieces with dull edges. This greatly diminishes the risk of lacerations if a display screen were to break due. This is particularly important in environments like operating rooms, emergency departments, or patient rooms where accidental damage might occur. If a display is damaged, the priority is to prevent injury to anyone nearby and to quickly and safely manage the situation. Tempered glass facilitates this. Furthermore, the inherent strength of tempered glass reduces the likelihood of breakage in the first place, contributing to a safer overall environment. Its ability to withstand the rigors of daily clinical use, including frequent cleaning and repositioning, also means it maintains its integrity over time, preventing failures that could compromise safety or procedural efficacy.

Comparative Safety Features

Let’s compare the safety aspects of different glass types commonly considered for displays.

| Feature | Annealed Glass (Standard) | Tempered Glass | Laminated Glass |

|---|---|---|---|

| Breakage Pattern | Large, sharp shards | Small, blunt granules | Fragments adhere to interlayer |

| Impact Strength | Low | High (4-5x annealed) | High (interlayer absorbs energy) |

| Injury Risk | High | Low | Very Low (shards contained) |

| Post-Breakage | Shards scatter widely | Granules may fall, less dangerous | Glass largely stays in place |

While laminated glass also offers excellent safety, tempered glass provides a strong balance of impact resistance, safe breakage, and optical clarity suitable for medical display front surfaces, often combined with AR coatings. The increased strength also contributes to overall device stability, preventing flex or damage to internal components.

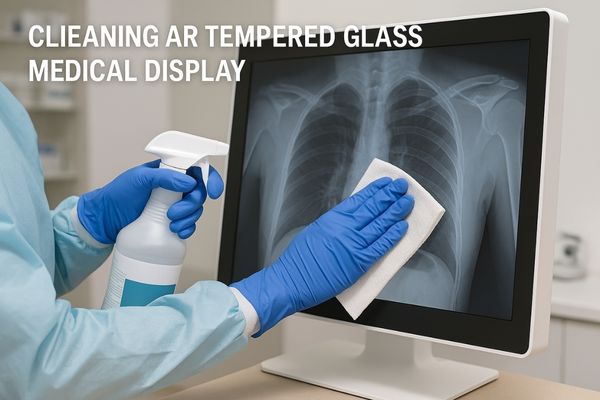

How does AR-treated tempered glass support infection control protocols?

Is maintaining a sterile environment a constant challenge? Surfaces in clinical settings must be easy to clean and disinfect. AR-treated tempered glass offers features that aid infection control.

AR-treated tempered glass supports infection control with its smooth, non-porous surface. This makes it easy to clean and disinfect thoroughly with hospital-grade agents without damaging the glass or its anti-reflective properties.

I recognize that infection prevention8 is a critical aspect of healthcare. The materials used in medical devices must support rigorous hygiene practices. AR-treated tempered glass9 excels in this regard. Its surface is exceptionally smooth and seamless. This lack of pores or crevices means there are fewer places for microorganisms like bacteria and viruses to harbor and multiply. Consequently, cleaning and disinfection are more effective. Medical staff can confidently wipe down these displays with standard hospital-grade disinfectants, knowing that the surface can withstand repeated chemical exposure without degrading. The anti-reflective coating itself is typically very durable and resistant to common cleaning agents when applied correctly. This ensures that the optical performance of the display is maintained even with frequent cleaning. In sterile environments such as operating rooms or intensive care units, where the risk of healthcare-associated infections (HAIs)10 is high, having equipment that is easy to keep hygienically clean is paramount. AR-tempered glass directly contributes to a safer patient environment by facilitating effective infection control measures.

Key Properties Aiding Disinfection

Several properties of AR-treated tempered glass make it suitable for environments requiring strict hygiene.

- Chemical Resistance: High-quality AR coatings and tempered glass are resistant to a wide range of disinfectants, including alcohol-based solutions and quaternary ammonium compounds, commonly used in hospitals. This ensures the optical and physical integrity of the screen is not compromised by cleaning protocols.

- Non-Porous Surface: Glass, by its nature, is non-porous. This prevents the absorption of liquids and contaminants, making it easier to remove them completely during cleaning.

- Durability: The robust nature of tempered glass means it can withstand the physical act of wiping and scrubbing without scratching easily, ensuring the surface remains smooth and easy to clean over its lifespan.

Importance in High-Touch Areas

Medical displays, especially those on mobile carts or at patient bedsides, are high-touch surfaces.

| Feature | Benefit for Infection Control |

|---|---|

| Smooth, seamless surface | Reduces microbial harboring sites, facilitates easy cleaning. |

| Resistance to disinfectants | Allows for effective disinfection without material degradation. |

| Durability | Withstands frequent cleaning cycles over the product’s lifespan. |

| Clear visibility (AR) | Reduces need to touch screen to adjust view due to glare. |

By choosing displays with AR-treated tempered glass, healthcare facilities can better adhere to their infection control protocols, ultimately contributing to patient and staff safety.

How does Reshin apply AR tempered glass in its surgical display lineup?

Are you looking for surgical displays that combine top-tier visuals with robust, hygienic design? The choice of screen material is critical. We carefully integrate advanced glass technology into our products.

Reshin applies multi-layer AR-coated tempered glass in its surgical displays, often with full lamination and anti-smudge treatments. This provides exceptional image clarity, glare reduction, impact resistance, and an easy-to-clean surface for optimal surgical performance.

In our pursuit of optimal surgical visualization, we have placed significant emphasis on the protective front glass of our displays. For our surgical monitor lines, such as the MS series, we utilize high-quality tempered glass that undergoes a multi-layer anti-reflective coating11 process. This multi-layer approach is more effective than single-layer coatings as it reduces reflections across a broader spectrum of light wavelengths, leading to superior glare control under diverse OR lighting conditions. The result is a clearer, crisper image with enhanced contrast, allowing surgeons to perceive subtle details critical for positive outcomes. Furthermore, we often employ a full lamination technique12. This involves optically bonding the AR-tempered glass directly to the LCD panel. Full lamination eliminates the air gap between the glass and the display, which reduces internal reflections, further boosts contrast, and improves readability. It also enhances the display’s structural integrity, making it more resistant to impact and preventing dust or moisture ingress. To complete the solution, an anti-smudge (oleophobic) coating13 is frequently applied. This helps repel fingerprints and bodily fluids, making the screen easier to clean and maintain its pristine view. This comprehensive approach ensures our surgical displays deliver not just excellent optical performance but also the durability and hygienic properties essential for the demanding surgical environment. Our 32" and 43" 4K monitors, for example, benefit greatly from this technology, providing the clarity surgeons need.

Advanced Glass Integration in Reshin Displays

Our strategy for incorporating AR tempered glass involves several key technological considerations:

- Multi-Layer AR Coating: We specify coatings that typically reduce surface reflectance to less than 0.5% or 1%, compared to around 4-8% for untreated glass. This significantly improves light transmission and reduces eye strain.

- Optical Bonding (Full Lamination): This process uses a clear adhesive to bond the glass to the LCD.

- Benefits:

- Reduces parallax error for touchscreens (if applicable).

- Increases ruggedness and shock absorption.

- Prevents condensation and fogging in the air gap.

- Benefits:

- Anti-Smudge/Anti-Fingerprint Coatings: These oleophobic and sometimes hydrophobic coatings create a low surface energy layer that repels oils and water, making the screen easier to wipe clean and maintain visibility.

This meticulous integration ensures that the protective glass enhances, rather than detracts from, the visual performance of our high-resolution medical displays, while also meeting the stringent physical and hygienic demands of clinical use. We believe this attention to detail in material science and engineering is crucial for providing medical professionals with tools they can rely on.

Conclusion

Tempered anti-reflective glass is vital for medical displays. It ensures clear visibility, protects the equipment, and supports hygiene. This technology directly enhances diagnostic accuracy and surgical precision. To equip your facility with medical displays featuring premium tempered AR glass, contact Reshin at martin@reshinmonitors.com.

-

Explore how AR glass enhances visual clarity in medical procedures, crucial for accurate diagnostics and surgical focus. ↩

-

Learn about the impact of visual clarity on diagnostic accuracy, essential for effective patient care and treatment decisions. ↩

-

Discover the importance of visual clarity in minimally invasive surgery, enhancing precision and patient outcomes. ↩

-

Explore the advantages of tempered glass in medical settings, including its impact resistance and durability, crucial for operational efficiency. ↩

-

Discover innovative design strategies that prioritize user and patient safety in healthcare environments, ensuring better outcomes. ↩

-

Learn about the importance of fracture patterns in glass materials and how they impact safety in various applications. ↩

-

Explore the safety advantages of tempered glass, especially in medical settings, to understand its critical role in patient safety. ↩

-

Explore this resource to understand essential strategies for infection prevention, crucial for patient safety and healthcare quality. ↩

-

Discover how AR-treated tempered glass enhances hygiene and safety in medical environments, making it a vital choice for healthcare facilities. ↩

-

Learn about HAIs and effective prevention strategies to improve patient outcomes and reduce infection rates in healthcare settings. ↩

-

Explore how multi-layer anti-reflective coatings enhance surgical display performance and improve visibility in operating rooms. ↩

-

Learn about the full lamination technique and its advantages for display clarity and durability in surgical environments. ↩

-

Discover the benefits of anti-smudge coatings for maintaining clean and clear surgical displays, crucial for hygiene. ↩