You invested in a high-resolution display for ultimate clarity. But over time, its performance drifts, and that initial precision fades, potentially compromising your diagnostic confidence.

Yes, advanced resolution displays require special calibration. Their high pixel density demands meticulous uniformity adjustments and adherence to standards like DICOM. Standard calibration methods are often insufficient to maintain the necessary accuracy and consistency across millions of pixels.

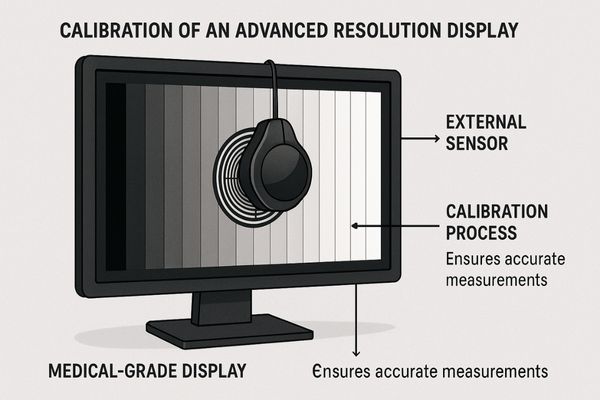

An advanced medical display is more than just a screen with a high megapixel count. It is a precision instrument. To function as intended, it must render images with absolute consistency in brightness, grayscale, and color. As pixel densities increase, the challenge of maintaining this consistency across the entire screen becomes much more complex. Simple visual adjustments are no longer adequate. These displays require specialized calibration procedures1 to ensure that every single pixel contributes to a diagnostically accurate image. This process is not a one-time setup but an ongoing commitment to quality assurance2, essential for meeting clinical standards and ensuring patient safety.

What calibration methods are necessary for maintaining accuracy in high-resolution medical displays?

You have a top-tier display. But are you using the right methods to keep it accurate? Relying on basic tools for an advanced screen can lead to undetected image distortions.

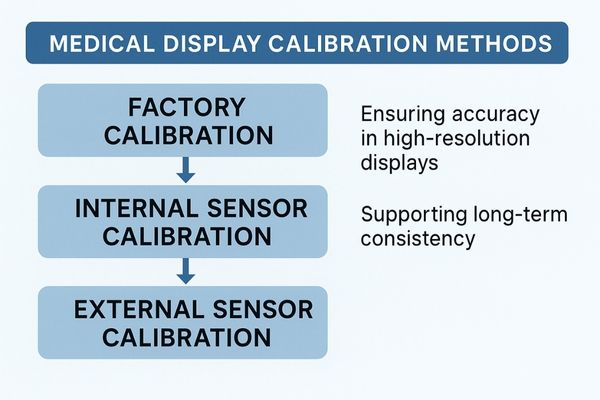

Maintaining accuracy requires a combination of factory pre-calibration, built-in sensor self-calibration, and periodic verification with external photometers. These methods work together to ensure luminance uniformity, color accuracy, and strict adherence to the DICOM GSDF curve.

Calibrating a high-resolution medical display3 is a multi-layered process. It begins at the factory, where we perform an initial, highly detailed calibration. This process measures and corrects the output of every pixel region on the screen to create a uniform canvas. However, all displays experience performance drift over time. To counteract this, high-end monitors use automated internal systems. Some, like our MD120C 12MP High-Precision Diagnostic Monitor, feature a built-in front sensor that swings into place to measure the screen and make automatic adjustments. This ensures consistent performance without interrupting clinical workflow. Finally, for the highest level of quality assurance, hospitals should perform periodic checks with a high-precision external sensor4 and specialized software. This third-party verification confirms that both the factory and internal calibrations are performing correctly. This comprehensive approach is the only way to guarantee that a high-resolution display remains a reliable diagnostic tool throughout its service life.

Comparison of Calibration Methods

| Method | Description | Best For | Frequency |

|---|---|---|---|

| Factory Calibration | Initial, highly detailed uniformity and color correction performed by the manufacturer. | Establishing the baseline performance of a new monitor. | Once (at time of manufacture) |

| Internal Sensor Calibration | An integrated sensor automatically measures and adjusts the display’s output. | Daily or weekly consistency checks with minimal user intervention. | Automated (Scheduled) |

| External Sensor Calibration | A high-precision external photometer is used with software for a full audit and recalibration. | Annual quality assurance or when troubleshooting display issues. | Annually (or as needed) |

How does higher pixel density impact the frequency or type of calibration required?

You have monitors with different resolutions. You wonder if they all need the same care. Applying a one-size-fits-all calibration schedule could mean neglecting your most advanced screens.

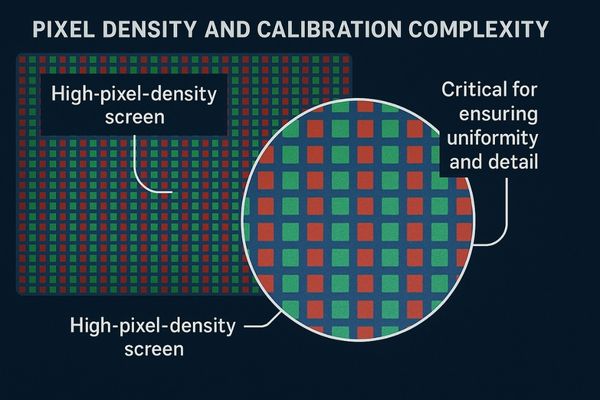

Higher pixel density increases the importance of uniformity calibration. While it may not strictly increase the frequency, it makes each calibration more critical. Ensuring millions of tiny, tightly packed pixels have consistent brightness and color requires more sophisticated sensor technology and correction algorithms.

The primary impact of higher pixel density is on the complexity of uniformity calibration5. A 2MP display has about two million pixels to manage. An 8MP 4K display has over eight million. As the number of pixels increases and their physical size decreases, the potential for tiny variations in luminance from one part of the screen to another also grows. Even a small deviation, when multiplied across thousands of pixels, can create a noticeable patchiness or blotchiness that could obscure subtle pathology. Therefore, the calibration process for a high-density screen6 must be more granular. The sensors used must be able to accurately measure smaller areas of the screen, and the monitor’s internal electronics must have sophisticated look-up tables (LUTs) to apply fine-tuned corrections to different screen regions. This is why a display like our MD50C 5MP Color Mammography Monitor undergoes such a rigorous factory calibration process. It is essential to ensure that the brightness of a pixel in the top-left corner is identical to one in the bottom-right, guaranteeing a perfectly uniform canvas for diagnosis.

Are there specific tools or software used for calibrating advanced resolution displays?

You need to perform a calibration. But do you have the right equipment? Using consumer-grade tools on a medical display will not provide the precision required for clinical work.

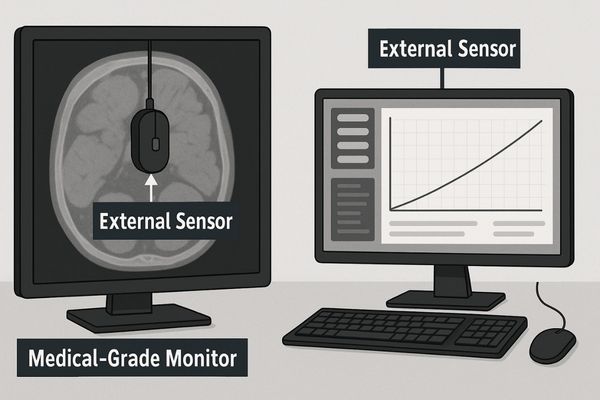

Yes, specialized tools are essential. These include medical-grade external photometers or colorimeters and proprietary quality assurance software. This software often automates the process, running test patterns, taking measurements, and generating compliance reports for hospital records.

Calibrating an advanced resolution medical display is not a task for off-the-shelf hardware or software. The process requires a dedicated ecosystem of tools designed for clinical precision. The first component is the sensor. While some monitors have built-in sensors for daily checks, periodic audits require a high-precision external photometer7. These devices are more sensitive than integrated sensors and provide an unbiased measurement of the screen’s true output. The second component is the quality assurance (QA) software8. This software is the brain of the operation. It communicates with the sensor and the monitor, displaying specific test patterns (like those from the AAPM TG18 standard) for the sensor to measure. The software then compares these measurements against the target standard, such as the DICOM GSDF. If deviations are found, it generates a new correction profile and uploads it to the monitor. This software also creates a detailed report, providing an essential audit trail for hospital accreditation and quality control. Our MD45C Dual-screen Diagnostic Monitor is compatible with leading QA software suites, simplifying this critical task for IT and clinical engineering departments.

Key Calibration Tools and Their Functions

| Tool | Type | Primary Function |

|---|---|---|

| External Photometer | Hardware | Measures the precise luminance (brightness) of the display. Used for grayscale and DICOM calibration. |

| External Colorimeter | Hardware | Measures the precise color coordinates (chromaticity) of the display. Used for color-critical applications. |

| QA Software | Software | Automates the calibration process, generates test patterns, analyzes sensor data, and creates compliance reports. |

| Built-in Sensor | Hardware (Integrated) | Provides automated, quick checks of screen consistency to counteract short-term drift. |

Why do manufacturers like Reshin emphasize regular calibration for their high-end monitors?

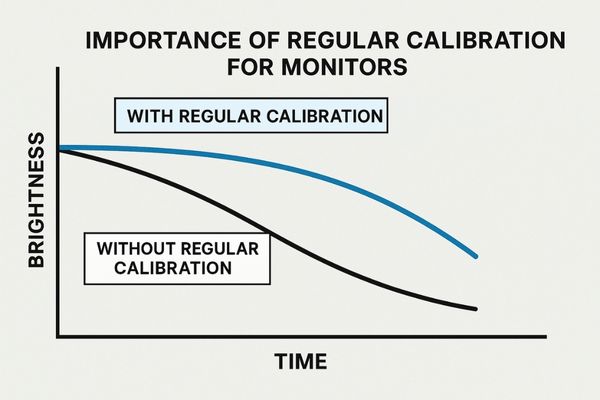

You buy a premium monitor and assume it will stay perfect. But this is a risky assumption. Without regular checks, even the best display’s performance will degrade over time.

We emphasize regular calibration because all display components, especially the backlight and LCD panel, age over time. This aging causes performance to "drift" away from the perfect factory settings. Regular calibration corrects this drift, ensuring diagnostic accuracy and protecting the investment.

A medical monitor is a dynamic system, not a static object. Its components are under constant stress. The backlight, whether LED or CCFL, slowly loses its maximum brightness over thousands of hours of use. The liquid crystals in the panel can also change their response characteristics over time due to heat and electrical charge. This gradual degradation is known as "drift." If left uncorrected, this drift will cause a monitor to fall out of compliance with the DICOM standard9, leading to images that are too dark, too bright, or have inconsistent grayscale rendering. A radiologist could unknowingly lose the ability to perceive subtle differences in tissue density. We emphasize regular calibration10 because it is the only way to counteract this natural aging process. By regularly measuring the display’s output and making small adjustments, the monitor’s performance can be held stable at its optimal level for many years. This proactive maintenance, especially for workhorses like our MD32C 3MP Diagnostic Monitor, is fundamental to ensuring long-term diagnostic confidence and maximizing the return on a significant equipment investment.

Does specialized calibration contribute to compliance with standards such as DICOM for medical imaging?

You know calibration is important. But how does it directly relate to compliance? Understanding this link is key to justifying the time and resources needed for proper maintenance.

Yes, specialized calibration is the primary mechanism for maintaining DICOM Part 14 compliance. The DICOM standard defines how a display should look; calibration is the active process of adjusting the monitor to ensure it meets and continues to meet that standard.

DICOM compliance11 is not a permanent feature of a monitor. It is a state of performance that must be actively maintained. The DICOM Part 14 standard sets a very specific target for how a monitor should display shades of gray, known as the Grayscale Standard Display Function (GSDF)12. A monitor is only compliant when its actual performance matches this target curve. When a monitor like our MD85CA leaves our factory, it is perfectly calibrated to the GSDF. However, due to the inevitable performance drift over time, its output will slowly move away from this target. Specialized calibration is the tool used to measure this deviation and correct it. The calibration software measures the monitor’s current grayscale response, compares it to the ideal DICOM curve, and then fine-tunes the monitor’s internal settings to bring it back into alignment. Without this regular, specialized calibration, a monitor cannot be considered truly DICOM compliant over the long term. It is the essential link between the standard and the actual performance of the device in a clinical setting.

Conclusion

Advanced resolution displays demand special, regular calibration to counteract performance drift. This process is essential for maintaining diagnostic accuracy, ensuring uniformity, and guaranteeing continuous compliance with critical medical standards like DICOM. To discover medical displays with intelligent, automated calibration features, contact Reshin at martin@reshinmonitors.com.

-

Understanding specialized calibration procedures is crucial for ensuring accurate medical imaging and patient safety. ↩

-

Exploring the importance of quality assurance can enhance your knowledge of maintaining high standards in medical imaging. ↩

-

Understanding calibration practices is crucial for maintaining display accuracy in medical settings. ↩

-

Exploring this topic will provide insights into ensuring the reliability of diagnostic tools. ↩

-

Understanding uniformity calibration is crucial for ensuring accurate and consistent display performance, especially in medical imaging. ↩

-

Exploring the challenges of high-density screens can provide insights into the complexities of modern display technology and its applications. ↩

-

Learn about the role of high-precision external photometers in ensuring accurate medical display measurements and audits. ↩

-

Explore this link to understand how QA software enhances calibration accuracy and compliance in medical displays. ↩

-

Understanding the DICOM standard is crucial for ensuring compliance and optimal image quality in medical diagnostics. ↩

-

Regular calibration is essential for maintaining monitor performance and diagnostic accuracy over time. ↩

-

Understanding DICOM compliance is crucial for ensuring accurate medical imaging and patient safety. Explore this link for in-depth insights. ↩

-

The GSDF is vital for consistent image quality in medical displays. Discover more about its significance and application in healthcare. ↩