Hospitals face growing pressure to reduce their environmental impact, but medical equipment consumes significant energy. This conflict challenges sustainability goals. Green manufacturing in medical displays offers a direct solution.

Energy-efficient designs, eco-friendly materials, product longevity, and environmental certifications are key pillars of green manufacturing in medical displays. These factors contribute to sustainable healthcare and directly align with modern hospital ESG goals.

Sustainability is no longer a secondary consideration in healthcare. It has become a core component of responsible hospital management1. As manufacturers, we have a critical role to play in this global shift. The equipment we design and produce has a direct impact on our partners’ operational costs, carbon footprint2, and ability to meet their ESG targets. We believe that thoughtful engineering and responsible production are not just good for the planet; they are essential for building better, more valuable medical technology. Let us explore how these principles are put into practice.

Energy-Efficient Designs Reduce Operational Carbon Footprint

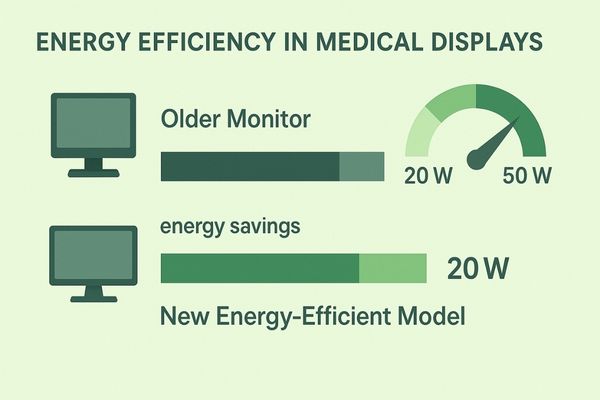

High energy bills and carbon taxes hurt hospital budgets. Medical displays run constantly, contributing significantly to this problem. Energy-efficient designs directly lower these operational costs and emissions.

Energy-efficient medical displays reduce power consumption. This helps hospitals cut operational carbon emissions, which aligns their operations with global decarbonization trends and lowers utility expenses.

A single medical display may not seem like a major power drain, but a large hospital utilizes hundreds of them across various departments. These displays often operate for extended periods, sometimes 24/7 in emergency rooms or intensive care units. The cumulative energy consumption is substantial. Our engineering focus has shifted to maximizing performance per watt. Modern displays achieve this primarily through the use of LED backlight technology3, which is significantly more efficient than older Cold Cathode Fluorescent Lamp (CCFL) systems. Beyond the backlight, intelligent features further reduce power usage. For example, built-in ambient light sensors4 can automatically adjust screen brightness to the minimum level required for a clear diagnosis, preventing unnecessary energy waste. Similarly, presence sensors can place the display in an ultra-low-power standby mode when no user is detected. A basic but essential workhorse like the MD22CA – 2MP Diagnostic Monitor incorporates these efficiencies, leading to tangible savings in electricity costs and a measurable reduction in the hospital’s carbon footprint over the device’s lifespan.

| Feature | Energy-Saving Mechanism | Impact on Hospital |

|---|---|---|

| LED Backlight | Higher light output per watt vs. CCFL | Lowers overall power consumption. |

| Ambient Light Sensor | Adjusts brightness based on room lighting | Prevents running at max brightness unnecessarily. |

| Presence Sensor | Enters low-power mode when idle | Drastically reduces energy use during downtime. |

Eco-Friendly Materials Support Sustainable Production

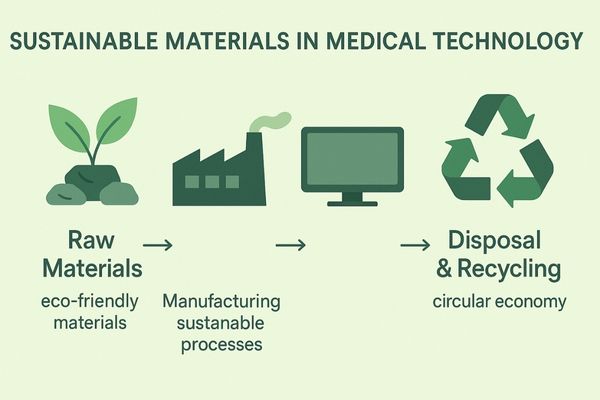

The production and disposal of electronics can introduce toxic materials into the environment. This poses a long-term risk to ecosystems and public health. This requires a commitment to safer materials.

Using recyclable or low-toxicity materials in display production lowers the overall environmental impact. This responsible approach also strengthens a brand’s reputation as an eco-friendly partner.

Our responsibility for a product’s environmental impact begins long before it reaches the hospital. It starts with the selection of raw materials. We are committed to minimizing the use of hazardous substances in our manufacturing processes. This means strict compliance with global standards like the Restriction of Hazardous Substances (RoHS)5 directive, which limits the use of materials like lead, mercury, cadmium, and certain flame retardants. We prioritize using recycled and recyclable materials6 wherever possible, especially in components like the display enclosure and internal structural elements. This reduces our reliance on virgin plastics and metals, lowering the carbon footprint of production. Our commitment extends to packaging. We have moved away from expanded polystyrene (styrofoam) in favor of molded pulp and recycled cardboard, which are biodegradable and easier to recycle. This focus on material health ensures that products like the MS247SA – 24" FHD Endoscopic Monitor are not only effective in the operating room but also safer for the environment throughout their entire lifecycle.

Longevity and Reliability Minimize Electronic Waste

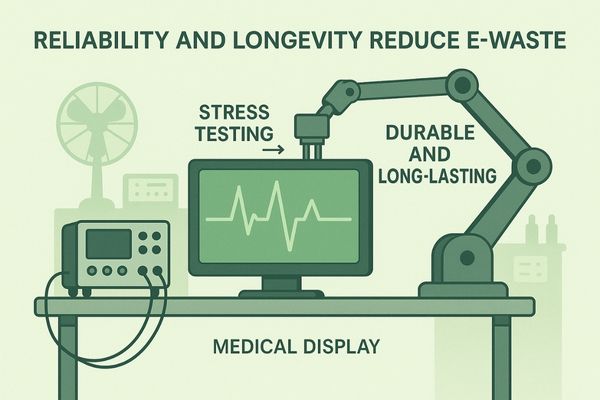

Frequent device replacement is expensive for hospitals and creates a mountain of electronic waste. Unreliable equipment also disrupts critical clinical workflows. Durable displays solve both problems at once.

Extending the lifespan of a display and improving its reliability are core sustainability strategies. Durable devices minimize disposal rates, directly reducing the generation of electronic waste at its source.

The most sustainable product is one that does not need to be replaced. Electronic waste, or e-waste7, is one of the fastest-growing waste streams in the world, and it is filled with valuable but also potentially hazardous materials. A key pillar of our green manufacturing philosophy is to design products that last. This starts with using high-quality components, from industrial-grade power supplies to durable capacitors that can withstand the demands of a hospital environment. Every design undergoes rigorous testing, including thermal cycling, shock and vibration tests, and thousands of hours of operational stress testing. This ensures that the product maintains its performance and DICOM compliance for many years. A reliable display with a longer operational life reduces the total cost of ownership for the hospital and significantly cuts down on e-waste. By building a product like the MS321PC – 32" 4K Surgical Monitor to a high standard of durability, we are making a conscious choice to favor longevity over disposability, which is a fundamental principle of the circular economy8.

Compliance with Environmental Certifications Builds Trust

Hospitals struggle to verify all the "green" claims made by various suppliers. This lack of clear verification creates procurement risk. Recognized certifications provide objective, third-party proof of compliance.

Displays certified to international standards like RoHS or Energy Star gain easier acceptance from hospital procurement teams. This verified compliance becomes a significant factor in market competitiveness.

In a world full of green marketing claims, trust must be earned through transparent, verifiable actions. For medical device manufacturers, this verification comes in the form of globally recognized environmental certifications9. These standards provide hospital procurement departments with a clear, objective benchmark for evaluating a product’s environmental performance. Achieving these certifications is not a simple process. It requires disciplined engineering, careful supply chain management, and detailed documentation. Adhering to these standards demonstrates a genuine commitment to sustainability that goes beyond words. For our customers, seeing a certification like Energy Star10 or RoHS on a product specification sheet simplifies their decision-making process. It provides them with the confidence that the device meets stringent criteria for energy efficiency and material safety. This compliance is essential for winning tenders, especially with government and large hospital networks that have explicit sustainability requirements. The MD26C – 24" Diagnostic Monitor is developed to meet these key international standards, ensuring it is a responsible choice for any healthcare institution.

| Certification | Focus Area | What It Means for Hospitals |

|---|---|---|

| Energy Star | Energy Efficiency | Lower electricity costs and reduced carbon footprint. |

| RoHS | Hazardous Substances | Ensures the product is free from toxic materials like lead and mercury. |

| WEEE | E-Waste Management | Guarantees the manufacturer has a plan for responsible end-of-life recycling. |

Green Manufacturing Aligns with Hospital ESG Goals

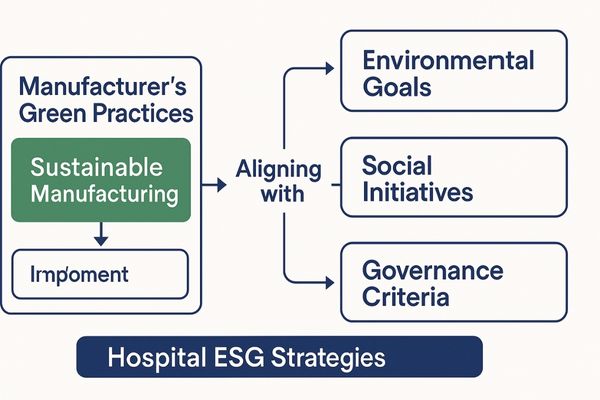

Hospitals are increasingly judged on their overall environmental and social impact. Their supply chain is a major part of this assessment. Partnering with sustainable suppliers directly helps them achieve their goals.

Green manufacturing practices align perfectly with the Environmental, Social, and Governance (ESG) strategies of modern hospitals. This alignment will become a core competitive advantage for medical device suppliers.

The framework of Environmental, Social, and Governance (ESG) is reshaping how large organizations, including hospitals, measure success. It is no longer enough to provide excellent patient care; leading healthcare institutions must also demonstrate that they are responsible corporate citizens. A significant part of a hospital’s environmental footprint comes from its supply chain, particularly the energy consumption and end-of-life disposal of its equipment. This is known as Scope 3 emissions11. When a hospital chooses a supplier that is committed to green manufacturing12, it is making a strategic decision that directly supports its ESG goals. It allows the hospital to report lower associated carbon emissions and demonstrate responsible procurement to its stakeholders, including patients, investors, and regulatory bodies. This partnership transforms the supplier-customer relationship. We are no longer just a vendor of hardware; we become a strategic partner in the hospital’s mission to be more sustainable. Advanced products like our MD85CA are designed with this partnership in mind, delivering clinical excellence within a framework of environmental responsibility.

Conclusion

Green manufacturing is not a trend; it is a fundamental responsibility. It creates medical displays that are more efficient, less wasteful, and fully aligned with the sustainability goals of modern healthcare.

📧 Interested in sustainable medical display solutions? Contact Martin at martin@reshinmonitors.com to learn how Reshin integrates eco-friendly practices into advanced display design.

-

Understanding responsible hospital management is crucial for improving sustainability practices in healthcare facilities. ↩

-

Exploring ways to reduce carbon footprint can lead to innovative strategies for sustainable healthcare. ↩

-

Explore this link to understand how LED backlight technology enhances efficiency and reduces energy consumption in medical displays. ↩

-

Learn about ambient light sensors and their role in optimizing display brightness, leading to significant energy savings. ↩

-

Understanding RoHS is crucial for anyone interested in environmental compliance and sustainable manufacturing practices. ↩

-

Exploring the benefits of these materials can enhance your knowledge of sustainable practices and their impact on the environment. ↩

-

Understanding e-waste’s environmental impact can help you make informed choices about sustainability and recycling. ↩

-

Exploring the circular economy concept can provide insights into sustainable practices that reduce waste and promote resource efficiency. ↩

-

Explore this link to understand how environmental certifications enhance product credibility and support sustainable practices in healthcare. ↩

-

Discover why Energy Star certification is crucial for energy efficiency and how it impacts purchasing decisions in the medical field. ↩

-

Understanding Scope 3 emissions is crucial for hospitals aiming to reduce their environmental impact and enhance their ESG strategies. ↩

-

Exploring green manufacturing can reveal how hospitals can improve sustainability and align with their ESG goals through responsible sourcing. ↩