Raw imaging data is uncalibrated and often contains digital noise. This makes accurate clinical interpretation impossible, risking patient safety and introducing potential errors in diagnosis or surgical procedures.

Digital Signal Processing in medical-grade monitors ensures real-time, standard-compliant visualization by managing grayscale mapping, color calibration, and image enhancement. In surgery, it delivers ultra-low latency imaging; in diagnostics, it guarantees accurate, consistent images for confident decision-making.

Digital Signal Processing1, or DSP, is the sophisticated engine at the heart of every high-performance medical monitor. It functions as a specialized computer dedicated to a single, critical task: transforming the raw, unprocessed data from an imaging source—like an endoscope or a CT scanner—into a visually accurate, stable, and clinically reliable image2. This transformation is not a simple passthrough of data. It involves a complex sequence of calculations and corrections performed in real time. For surgical applications, the priority is delivering this processed image with imperceptible delay. For diagnostic radiology, the focus shifts to ensuring that every single shade of gray conforms perfectly to international standards. Without this powerful processing core, even the most advanced LCD panel would be incapable of meeting the stringent demands of modern healthcare. The DSP is what unlocks the full clinical potential of the imaging systems we rely on daily.

Role of DSP in Medical-Grade Monitors for Surgical and Diagnostic Applications

An advanced panel is useless if the signal feeding it is uncalibrated. This leads to inconsistent images that can hinder critical clinical work in both the OR and reading room.

DSP is the core engine of medical monitors, converting raw data into calibrated, standard-compliant images. It enables low-latency surgical video and precise grayscale mapping for accurate radiological diagnosis.

The role of Digital Signal Processing3 is fundamental yet distinct across different clinical settings. It acts as a specialized translator, ensuring the raw data from an imaging modality is rendered perfectly for the intended application. In surgical environments, its primary function is to deliver an image with both speed and clarity. When a surgeon is navigating complex anatomy with a laparoscope, the DSP must process the video feed with near-zero latency, ensuring that what the surgeon sees on the screen is perfectly synchronized with their hand movements. A display like the MS270P relies on its DSP to achieve this real-time performance. In diagnostic applications, the DSP’s role shifts to an obsessive focus on accuracy and consistency. It meticulously maps every pixel to the DICOM Grayscale Standard Display Function4 (GSDF), corrects for any non-uniformity in the panel’s backlight, and ensures the image remains stable over thousands of hours of use. It is this processing that gives a radiologist the confidence to diagnose subtle pathologies from a CT scan or X-ray, knowing the image has not been distorted or misinterpreted by the display itself.

Real-Time Performance and Low-Latency Processing in the Operating Room

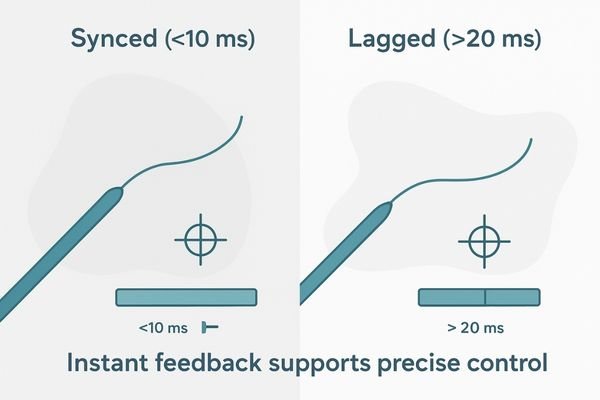

Any delay between a surgeon’s action and the on-screen image can be disorienting. This latency disrupts hand-eye coordination, elevating the risk of procedural errors and patient injury.

Optimized DSP pipelines in surgical monitors use minimal buffering and high-bandwidth interfaces. This achieves single-digit millisecond latency, ensuring perfect synchronization between surgical instruments and the displayed image.

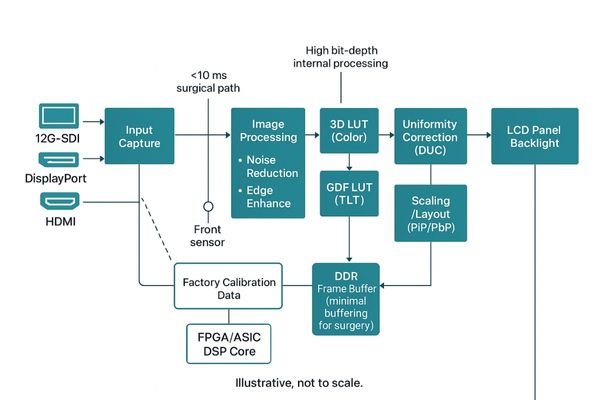

In the operating room, latency is not a measure of inconvenience; it is a critical safety parameter. A delay of even 50 milliseconds between a surgeon’s actions and the visual feedback can compromise procedural integrity. To combat this, the DSPs within medical-grade surgical monitors are engineered for one primary purpose: speed. The entire processing pipeline is optimized to minimize delay at every stage. This involves using high-bandwidth interfaces like 12G-SDI or DisplayPort to receive the raw video signal, employing efficient processing algorithms that require minimal data buffering, and often utilizing parallel processing techniques to handle multiple tasks simultaneously. The goal is to keep the total end-to-end latency5—from signal input to pixel illumination—in the single-digit millisecond range. This near-instantaneous response is what allows a surgeon to trust the image on a monitor like the MS321PB implicitly. It ensures that the delicate movements required for minimally invasive surgery6 are guided by a visual field that is a true, real-time representation of the anatomy, thereby maintaining flawless hand-eye coordination.

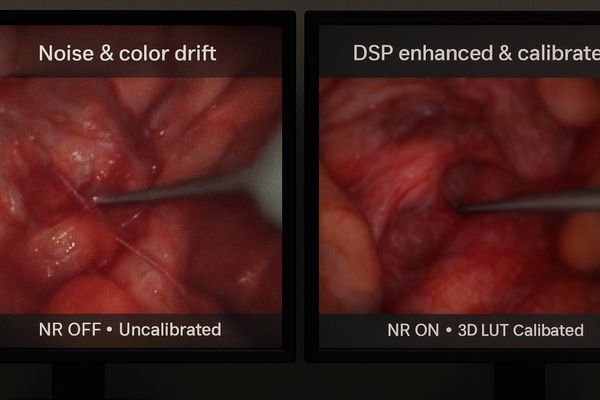

Color Accuracy, Image Enhancement, and Noise Reduction in Surgical Displays

Poor color reproduction can cause a surgeon to misidentify tissue types. Image noise can obscure fine details, creating uncertainty during critical moments of a procedure.

DSP uses 3D Look-Up Tables for precise color calibration and can implement real-time algorithms to sharpen details, reduce noise, and expand the color gamut without introducing artifacts.

Beyond speed, the DSP in a surgical display is responsible for delivering an image of the highest possible quality. Accurate color reproduction is paramount for tissue differentiation, helping surgeons distinguish between healthy tissue, blood vessels, and pathological areas. The DSP achieves this precision through the use of sophisticated 3D Look-Up Tables (LUTs)7, which allow for multi-dimensional color calibration far beyond simple red, green, and blue adjustments. This enables the monitor to be accurately calibrated to specific color gamut standards, such as BT.709 or the wider DCI-P3 space. Furthermore, the DSP can execute real-time image enhancement algorithms8. These can sharpen the appearance of fine structures like nerves and vessel walls or intelligently reduce the digital noise often present in images from endoscopic cameras, especially under low-light conditions. A monitor like the MS275P uses its DSP to perform these enhancements without introducing new visual artifacts or perceptible lag, ensuring surgeons receive a clear, clean, and color-accurate view of the surgical field at all times.

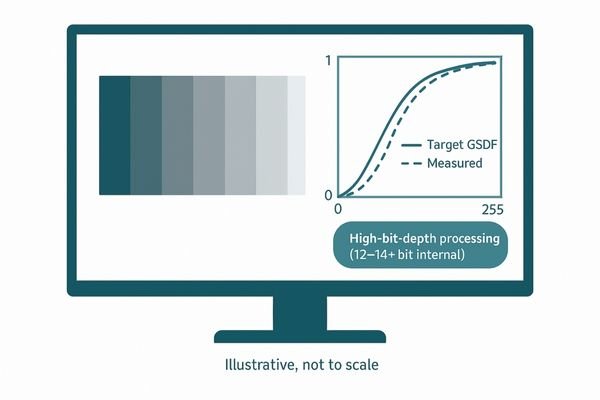

DICOM Part 14 Grayscale Mapping and High-Bit-Depth Processing in Radiology

Standard displays cannot render the full range of grayscale data in medical images. This can cause faint lesions or subtle fractures to be completely invisible to the radiologist.

DSPs in radiology monitors manage DICOM GSDF mapping to ensure perceptually uniform brightness. By processing images at 14 bits or higher, they enable precise visualization of over 1024 grayscale levels.

For diagnostic imaging, the DSP’s most critical task is the faithful reproduction of grayscale data according to the DICOM Part 14 Grayscale Standard Display Function (GSDF)9. This international standard is not arbitrary; it is based on human visual perception and ensures that changes in luminance on the screen correspond to how our eyes perceive differences in brightness. This is essential for diagnostic confidence. The DSP takes the raw pixel values from a medical image and, using a high-precision Look-Up Table10, maps them perfectly to the DICOM curve. To achieve this, high-end diagnostic monitors process data internally at a high bit depth, often 12, 14, or even 16 bits, even if the panel itself is 10-bit. This oversampling minimizes rounding errors and allows for extremely fine adjustments. A monitor like the MD120C leverages its DSP to render over 1024 distinct shades of gray simultaneously. This capability allows radiologists to perceive incredibly subtle variations in tissue density, which is crucial for detecting faint pathologies like early-stage tumors or hairline fractures.

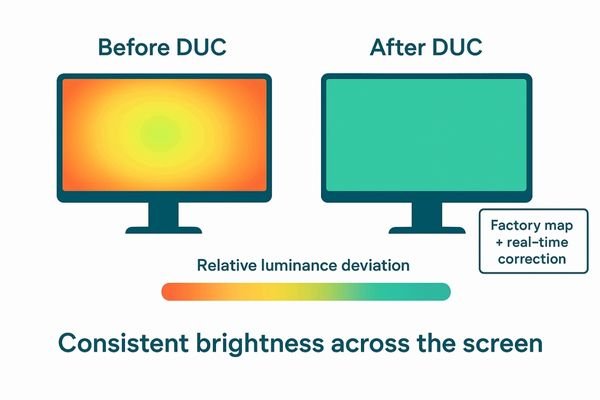

Uniformity Correction, Calibration Stability, and Image Consistency

Over time, all displays develop slight variations in brightness across the screen. This non-uniformity can cause an identical lesion to appear differently depending on its on-screen location.

DSP actively corrects for luminance and color non-uniformity in real time. Integrated sensors and feedback loops enable continuous self-calibration, ensuring stable, consistent image representation over the device’s lifetime.

No physical display panel is perfectly uniform from edge to edge. Minor variations in manufacturing and material properties can lead to some areas being slightly brighter or having a different color tint than others. If left uncorrected, this non-uniformity could lead a clinician to misinterpret image data. The DSP plays a vital role in mitigating this hardware limitation through a process known as Digital Uniformity Correction (DUC)11. During factory calibration, the screen is measured at hundreds of points, and a detailed correction map is stored in the monitor’s memory. The DSP then uses this map to adjust the signal for each pixel in real time, creating a perceptually uniform image. Furthermore, the DSP is key to long-term stability. Many advanced medical displays, including models like the MD52G, incorporate a front-facing sensor. This sensor works with the DSP in a closed-loop system, periodically measuring the monitor’s light output and automatically adjusting the internal LUTs to maintain perfect DICOM compliance12 and brightness stability as the backlight ages. This ensures consistent diagnostic quality day after day, year after year.

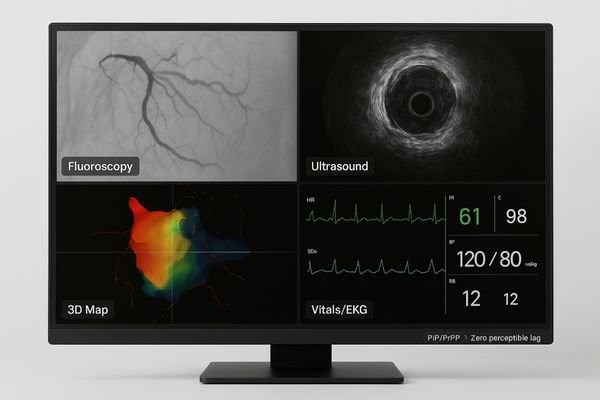

High-Resolution and Multi-Source Rendering for Complex Clinical Workflows

Managing multiple imaging sources on separate screens is inefficient and increases cognitive load. Clinicians waste time turning their heads instead of focusing on the patient.

DSP enables large, high-resolution monitors to render multiple video and data sources simultaneously without losing clarity. This capability streamlines complex workflows and improves situational awareness for clinical teams.

Modern clinical environments, from hybrid operating rooms to interventional radiology suites, rely on a multitude of imaging and data sources. The ability to view these sources simultaneously on a single, large-screen display is a major workflow enhancement, and it is made possible by powerful DSP13. A high-resolution 4K or 8K display requires an enormous amount of processing power to manage multiple inputs. The DSP must be able to receive, scale, position, and render video feeds from fluoroscopy, ultrasound, 3D mapping systems, and vital signs monitors—all at the same time and without introducing lag. This involves sophisticated Picture-in-Picture (PiP)14 and Picture-by-Picture (PbP) processing. For a large-format display like the MS550P, the DSP handles these complex layouts seamlessly, ensuring each source image is displayed with maximum clarity and diagnostic integrity. This consolidation of information reduces the cognitive load on the medical team, minimizes head-turning, and improves overall situational awareness, ultimately leading to faster, safer, and more efficient procedures.

| DSP Function | Role in Surgical Displays | Role in Diagnostic Displays |

|---|---|---|

| Latency Management | Ultra-low latency processing for real-time hand-eye coordination. | Less critical; focus is on processing accuracy. |

| Color & Grayscale | Precise 3D LUT color calibration for tissue differentiation. | High-bit-depth DICOM GSDF mapping for grayscale accuracy. |

| Image Enhancement | Real-time noise reduction and sharpness algorithms. | Generally avoided to maintain raw data integrity. |

| Uniformity & Stability | Corrects for color and luminance uniformity. | Actively corrects uniformity and performs self-calibration. |

| Multi-Source Display | Renders multiple live video feeds (PiP/PbP) with low latency. | Displays various static and dynamic images for review. |

DSP Architecture, LUT Design, and Hardware Implementation

A monitor’s performance is limited by its underlying hardware. A consumer-grade chipset cannot handle the complex, high-precision calculations required for certified medical imaging.

Medical displays use high-performance FPGA or ASIC-based DSPs with high-bit-depth LUTs. This hardware supports advanced features like 4K/60Hz processing, flexible gamma modes, and real-time scaling while maintaining clinical accuracy.

The robust performance of a medical-grade monitor is built upon a foundation of specialized hardware. Unlike consumer displays that use mass-market System-on-a-Chip (SoC) solutions, medical displays employ more powerful and flexible DSP architectures. These are typically built around either a Field-Programmable Gate Array (FPGA)15 or an Application-Specific Integrated Circuit (ASIC)16. FPGAs are highly customizable and allow engineers to design a processing pipeline tailored specifically for medical imaging tasks, which is ideal for complex, low-volume products like the MD85CA. ASICs are custom-designed chips that offer maximum performance and efficiency for a specific set of functions, often used in higher-volume models. At the core of these architectures are the Look-Up Tables (LUTs). These are not simple tables; they are high-bit-depth memory blocks (e.g., 14 or 16 bits) that store the precise correction values for gamma, grayscale, and color. This hardware allows the monitor to process high-bandwidth 4K/60Hz signals, support multiple gamma presets (e.g., DICOM, Gamma 2.2), and perform high-quality image scaling in real time, all while maintaining the internal processing precision required for uncompromised clinical performance.

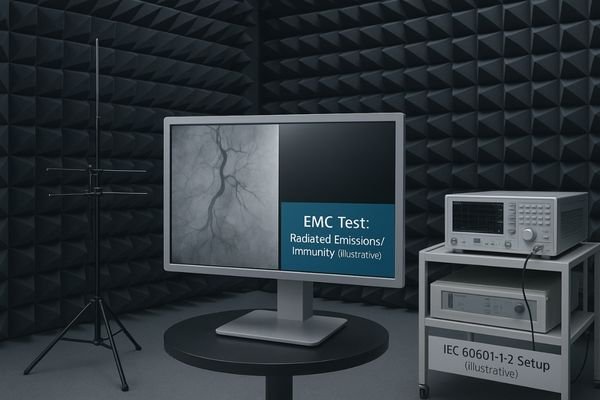

Compliance with IEC 60601 Safety Standards and Medical Imaging Guidelines

Using uncertified electronics in a patient environment is a safety risk. Electrical interference can disrupt life-support equipment, posing a direct threat to patient well-being.

DSP hardware and software design must adhere to IEC 60601-1 safety and 60601-1-2 EMC standards. This ensures the monitor operates safely near patients without causing or being susceptible to electromagnetic interference.

The design of the DSP and its surrounding electronics is heavily governed by strict regulatory standards for medical devices. Compliance is not optional; it is a prerequisite for market access and patient safety. The foundational standard is IEC 60601-117, which covers basic safety and essential performance, including protection against electrical hazards. Equally important, especially for a device with high-frequency processing, is IEC 60601-1-2, which addresses electromagnetic compatibility (EMC)18. The DSP must be designed with robust shielding and power filtering to ensure it does not emit electromagnetic interference that could disrupt other sensitive devices in the operating room or ICU, such as patient monitors or infusion pumps. Conversely, it must be immune to interference from external sources like electrosurgical units. The design of a compliant surgical display like the MS321PC involves careful circuit board layout, component selection, and extensive testing in certified laboratories to validate adherence to these standards. This rigorous process ensures the monitor can be deployed safely and reliably in any electrically noisy and patient-critical environment.

Conclusion

From low-latency surgical video to DICOM-compliant diagnostic review, Digital Signal Processing is the enabling technology that ensures medical-grade monitors deliver accurate, safe, and consistent performance.

📧 Want to integrate displays with advanced DSP capabilities into your clinical workflow? Contact Martin at martin@reshinmonitors.com to learn more about Reshin’s high-performance solutions.

-

Explore this link to understand how DSP enhances medical imaging, ensuring accuracy and reliability in diagnostics. ↩

-

Discover the techniques used to create clinically reliable images, crucial for effective diagnosis and treatment. ↩

-

Explore this link to understand how Digital Signal Processing enhances imaging in various clinical environments. ↩

-

Learn about the DICOM GSDF to see how it ensures accurate medical imaging for diagnostics. ↩

-

Understanding end-to-end latency is crucial for ensuring safety and precision in surgical procedures. ↩

-

Exploring the benefits of minimally invasive surgery can highlight its advantages in patient recovery and surgical outcomes. ↩

-

Understanding 3D LUTs can enhance your knowledge of color calibration in medical imaging, crucial for surgical precision. ↩

-

Exploring real-time image enhancement algorithms will reveal their importance in improving surgical visuals and outcomes. ↩

-

Understanding GSDF is vital for ensuring accurate grayscale reproduction in diagnostic imaging, enhancing diagnostic confidence. ↩

-

Exploring high-precision Look-Up Tables reveals how they optimize image quality and accuracy in medical diagnostics. ↩

-

Understanding DUC is crucial for ensuring accurate image interpretation in medical diagnostics. ↩

-

Exploring DICOM compliance will enhance your knowledge of standards that ensure image quality in healthcare. ↩

-

Learn about the critical role of DSP in managing complex imaging tasks for better patient outcomes. ↩

-

Explore how PiP technology enhances medical imaging and workflow efficiency in clinical settings. ↩

-

Explore this link to understand how FPGAs enhance medical imaging with customization and performance. ↩

-

Learn about ASICs and their role in optimizing performance for medical applications. ↩

-

Understanding IEC 60601-1 is crucial for ensuring safety and compliance in medical devices, making this resource invaluable for designers. ↩

-

Exploring EMC’s role in medical devices helps ensure they function safely in critical environments, a must-read for engineers. ↩