Glare from overhead lights on a display can obscure critical patient information. This forces clinicians to squint or reposition themselves, causing eye strain and risking diagnostic errors. Specialized anti-glare coatings offer a direct solution.

This article compares matte, glossy, and nano-texture coatings for medical displays. We explore add-on layers for cleanability and provide guidance on matching the right coating to specific clinical needs.

The surface of a medical display screen is a critical optical component. It is the final interface between the diagnostic image and the clinician’s eye. The coating applied1 to this surface dictates how it interacts with ambient light in the room. A poor choice can lead to distracting reflections that mask subtle details, while the right choice can enhance visibility and reduce user fatigue. The ideal coating is not the same for every situation; it depends entirely on the lighting conditions and the visual demands of the clinical task. We will now examine the different types of anti-glare technologies2 and their unique characteristics.

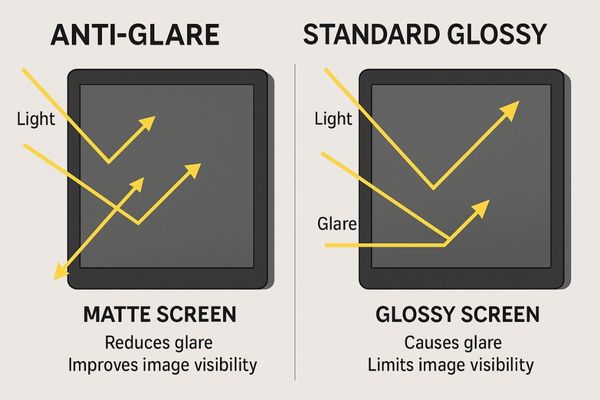

Matte Coatings Scatter Light for Reduced Reflection

Bright lights in an operating room cause distracting screen reflections. This forces you to constantly adjust your position just to see clearly. Matte coatings directly scatter this disruptive light away from your eyes.

Matte coatings use a micro-textured surface to diffuse ambient light, which significantly reduces direct, mirror-like glare. This is ideal for brightly lit environments but can slightly reduce perceived image sharpness.

The most common form of anti-glare technology is the matte coating3. This approach involves applying a layer with a roughened or micro-textured surface to the front of the display. Instead of reflecting light directly back at the viewer like a mirror, this textured surface scatters the incoming ambient light in many different directions. As a result, a bright overhead light source appears as a diffused, soft glow instead of a sharp, debilitating reflection. This makes matte coatings highly effective in environments with bright or uncontrollable lighting, such as general wards, busy clinics, or consultation rooms. However, this scattering mechanism is not without a trade-off. The same texture that diffuses external light can also slightly diffuse the light coming from the display’s pixels. This can cause a minor reduction in perceived sharpness and contrast. For general-purpose viewing on a device like the MD10C – 1MP Diagnostic Monitor, this effect is often negligible and well worth the significant reduction in glare.

| Coating Type | Glare Reduction | Image Sharpness | Best Environment |

|---|---|---|---|

| Matte | High | Good | Bright, Uncontrolled Light |

| Glossy | Low | Excellent | Dark, Controlled Light |

| Nano-Texture | High | Excellent | Bright, Demanding Use |

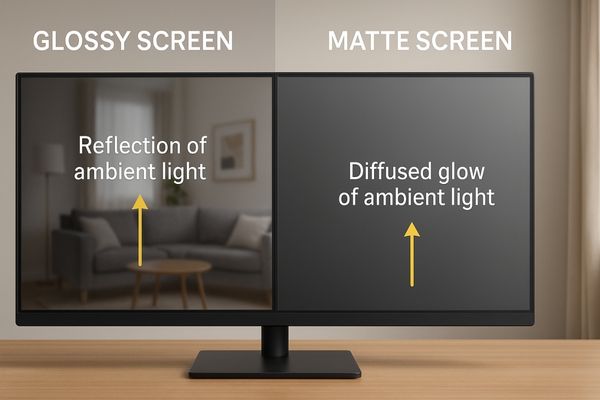

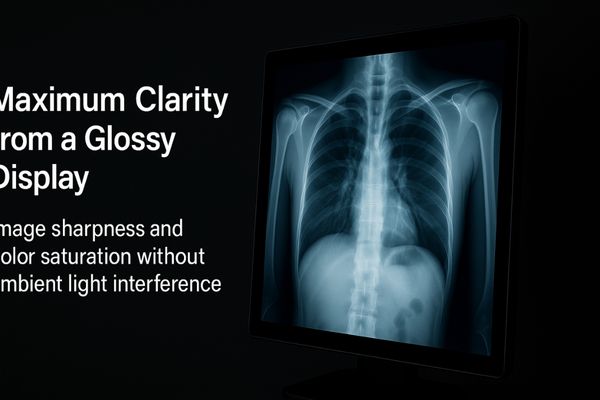

Glossy Coatings Preserve Clarity but Require Controlled Lighting

You need the sharpest possible image for accurate diagnosis. Standard anti-glare screens can sometimes soften critical details. Glossy screens offer maximum clarity but are highly vulnerable to reflections.

Glossy coatings have a perfectly smooth surface, allowing maximum light transmission from the panel. This results in the highest possible sharpness and color saturation but can create mirror-like reflections in bright settings.

A glossy screen4 has no textured anti-glare layer. Its surface is perfectly smooth, like a pane of glass. This allows the light from each pixel to travel in a straight, uninterrupted path to the viewer’s eye. The result is an image that appears exceptionally sharp, crisp, and vibrant, with deep blacks and saturated colors. For applications where detecting the most subtle textures and density variations is paramount, a glossy screen provides the highest level of image fidelity5. The significant drawback, however, is glare. Any direct light source in the room will create a clear, mirror-like reflection on the screen’s surface, which can obscure the image beneath it. For this reason, glossy displays are only suitable for environments where the ambient lighting can be completely controlled. This makes them an excellent choice for a dedicated radiology reading room, where lights are kept low to maximize diagnostic focus. In such a setting, a monitor like the MD33G – 3MP Grayscale Diagnostic Monitor can deliver its full visual potential without interference.

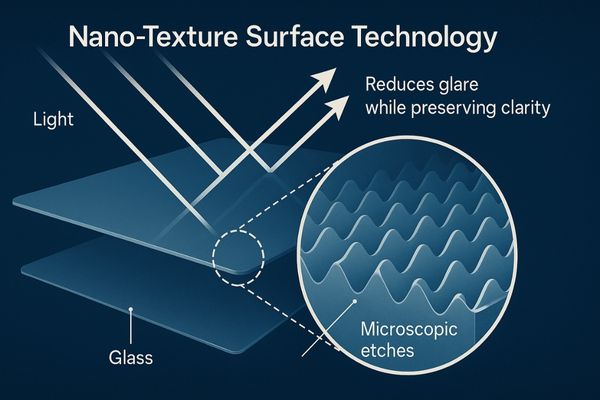

Nano-Texture Coatings Combine Low Glare with High Sharpness

You want the anti-glare performance of a matte screen without sacrificing image sharpness. The choice often feels like a difficult compromise. Nano-texture glass provides a superior solution without this trade-off.

Nano-texture coatings use microscopic etches on the glass itself to control light direction. This reduces glare effectively while preserving the original image sharpness, offering the best of both worlds.

Nano-texture technology6 represents a significant advancement over traditional coatings. Instead of applying a separate layer to the screen’s surface, the glass itself is precision-etched at a nanometer scale. This process creates a highly sophisticated surface that maintains sharpness while controlling reflections. Unlike the larger, random texturing of a matte finish that scatters light widely, the nano-texture guides light in a more controlled way. It dissipates the energy from ambient light sources to prevent glare but does so without interfering with the collimated light coming from the pixels directly behind the glass. The image therefore retains its native contrast and sharpness, free from the haziness or sparkle sometimes associated with matte coatings. This makes it the ideal solution for the most demanding clinical environments, such as the operating room, where bright overhead surgical lights coexist with the need for absolute image clarity. A high-performance display7 like the MS430PC – 43" 4K Surgical Monitor uses this technology to deliver uncompromising visual performance.

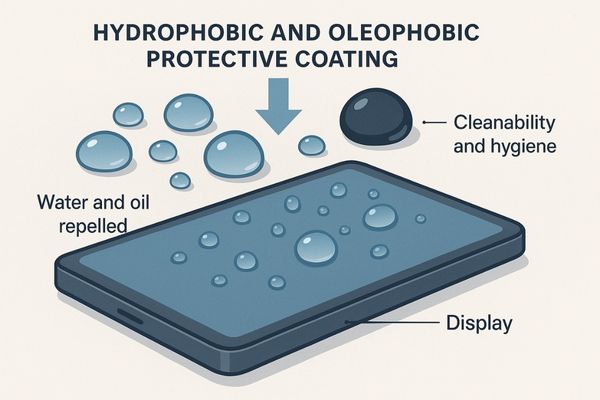

Hydrophobic and Oleophobic Layers Improve Cleanability

Keeping screens clean in a sterile environment is a constant challenge. Fingerprints, liquids, and smudges can compromise visibility and hygiene. Special coatings make cleaning faster and more effective.

Hydrophobic layers repel water, while oleophobic layers repel oils from fingerprints. These coatings create an ultra-smooth surface that prevents smudges from adhering, making the display easier to clean and maintain.

In addition to anti-glare properties, the outermost surface of a medical display can be treated with other functional layers. Two of the most important are hydrophobic and oleophobic coatings8. A hydrophobic (water-fearing) layer increases the surface tension of water, causing it to bead up and roll off rather than smearing. An oleophobic (oil-fearing) layer works similarly with oils, including the natural oils found in fingerprints. Together, these invisible coatings create a slick, non-stick surface. This a critical feature in a clinical environment. It means that fingerprints and other smudges do not adhere as strongly to the screen, and any splashes of liquid can be wiped away cleanly without leaving streaks or residue. This not only keeps the image clear but also supports infection control protocols9 by making the display easier to fully disinfect. For large, high-touch monitors used in surgery, such as the MS550P – 55" 4K Surgical Monitor, these coatings are essential for maintaining both optical clarity and a sterile field.

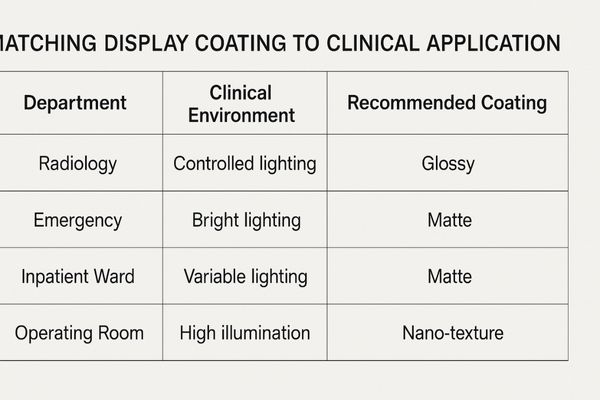

Coating Selection Should Match Clinical Application Needs

A coating that is perfect for a dark radiology room is completely wrong for a bright operating room. Choosing the wrong type leads to user frustration and suboptimal visual performance. The clinical application must guide the final choice.

The optimal anti-glare coating depends entirely on the specific clinical environment. Surgical teams need strong glare reduction, while radiologists may prioritize raw sharpness in controlled lighting. This choice directly impacts daily usability.

There is no single "best" anti-glare solution10 for all medical applications. The final decision must be based on a careful assessment of the intended use case. Different departments have vastly different lighting conditions and visual priorities. The goal is to align the screen’s properties with the environment to maximize diagnostic efficacy and user comfort. A multi-modality monitor11 like the MD85CA

– 8MP Multi-modality Diagnostic Monitor might be used in several different departmental settings, highlighting the importance of understanding these trade-offs.

Critical Application Environments

- Operating Room: This environment has intense, direct overhead lighting. The highest priority is aggressive glare reduction to prevent surgical lights from blinding the surgeon. Nano-texture is the ideal choice, with high-quality matte as a close second.

- Radiology Reading Room: This is a dark, light-controlled environment. The priority is maximum image sharpness and contrast to detect subtle pathologies. A glossy screen is highly effective here, as is a nano-texture screen.

- General Wards and ICU: Lighting is variable and often bright, with light from windows and overhead fixtures. A robust matte coating provides the most practical, all-around performance, effectively managing reflections from multiple sources.

| Clinical Area | Primary Lighting Condition | Key Priority | Recommended Coating |

|---|---|---|---|

| Operating Room | Intense, Direct | Maximum Glare Reduction | Nano-Texture, Matte |

| Radiology Room | Dark, Controlled | Maximum Sharpness | Glossy, Nano-Texture |

| ICU/Ward | Variable, Bright | All-Around Performance | Matte |

Conclusion

The right anti-glare coating is not a minor feature. It is essential for ensuring visual performance, enhancing user comfort, and supporting diagnostic confidence in every type of clinical setting.

📧 Want to equip your facility with displays featuring advanced anti-glare coatings? Contact Martin at martin@reshinmonitors.com to explore Reshin’s optimized solutions.

-

Learn about the impact of different coatings on visibility and user experience in medical displays, crucial for effective diagnostics. ↩

-

Explore this link to understand how various anti-glare technologies can enhance medical display performance and improve diagnostic accuracy. ↩

-

Explore this link to understand how matte coatings work and their benefits in reducing glare on displays. ↩

-

Understanding the pros and cons of glossy screens can help you make informed decisions for your display needs. ↩

-

Exploring image fidelity will enhance your knowledge of display technologies and their applications. ↩

-

Explore how Nano-texture technology enhances display clarity and reduces glare, making it ideal for clinical environments. ↩

-

Learn about the features that make high-performance displays essential for surgical precision and image clarity. ↩

-

Explore this link to understand how these coatings enhance display functionality and hygiene in medical environments. ↩

-

Learn about the importance of infection control protocols in healthcare settings and how they relate to medical display technology. ↩

-

Explore this link to discover various anti-glare solutions tailored for medical settings, enhancing both comfort and diagnostic accuracy. ↩

-

Learn about multi-modality monitors and how they can improve diagnostic efficacy across different medical departments. ↩