Signal & I/O Platform

Modular HDMI/DP/12G-SDI/Type-C matrix with unified firmware and drivers—one scalable board strategy that lowers cost and extends product lifetime.

Modular HDMI/DP/12G-SDI/Type-C matrix with unified firmware and drivers—one scalable board strategy that lowers cost and extends product lifetime.

Tool-less fronts, defined access points, cable guides, and FRU modules enable fast swaps in minutes—minimizing downtime in critical environments.

DICOM LUTs with CBS stabilization, APL tracking, noise suppression, shading correction, and window-level gamma for consistent, clinical imaging accuracy.

Custom fixtures, switching scripts, optical calibration rigs, and aging dashboards deliver repeatable outputs with data to prove compliance.

Full-flat AR/AG glass, sealed front, thermal tuning, and robust mechanics—ready for carts, arms, and VESA with serviceability built in.

Version-controlled ECNs, BOMs, ICDs, and calibration scripts with CE/IEC evidence ensure releases are auditable and integration-ready.

Pre-defined PIP/PBP/Quad layouts with lockable presets—speeding setup while keeping comparison workflows consistent across sites.

OSD guidelines, autorotation, and hotkeys reduce clicks and fatigue—supporting faster, safer operation for clinical teams.

Window-level gamma, white-point, and sharpness let users compare modalities side-by-side without moving to extra workstations.

Cart/arm/VESA compatibility with full-flat, cleanable fronts simplifies deployment and supports strict infection-control routines.

Scripted DICOM/gamma/white-point routines reach targets quickly and reproducibly—keeping output stable across departments.

Functional, boundary, and regression cases control evolution—catching issues early and preserving backwards compatibility.

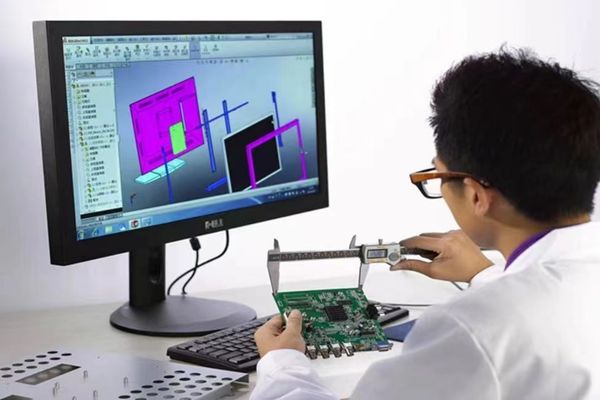

We deliver medical-grade displays with stable, repeatable quality—built under standardized SOPs, precision assembly and optical bonding, cleanroom-ready practices, calibrated output, and full manufacturing traceability.

Yes. We tailor templates, window-level gamma/white-point, interface mixes (HDMI/DP/12G-SDI/Type-C), optical options, and mounting. All changes are version-controlled.

Each unit’s SN links to station records: incoming checks, key parameters, test logs, firmware defaults, burn-in result, packing list, and outbound batch.

Audited, tiered AVL with PPAP/FAI; dual-sourcing where practical; ongoing IQC with AQL gates and supplier scorecards to manage risk.

We verify interface compatibility, run switching scripts, check multi-view templates, and tune display KPIs; parameters are locked in firmware by SN.

Scripted profiles per model expose early-life failures and drift under load; profiles and criteria can align with your acceptance plan.

Model-standard kitting verifies accessories; outer labels carry SN/batch/weight; palletizing follows destination rules with shared tracking.

Tickets tie to SN and build data; we run 5-Why/fishbone, apply temporary and permanent actions, update firmware/SOP, and notify partners.

To provide the best experiences, we use technologies like cookies to store and/or access device information, Consenting to thesetechnologies will allow us to process data such as browsing behavior or unique lDs on this site, Not consenting or withdrawing consentmay adversely affect certain features and functions.

We will contact you within 1 working day, please pay attention to the email with the suffix “@reshinmonitors.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@reshinmonitors.com”.